Optical fiber gas laser generation device used for generating 1.5-micron laser

A gas laser and generating device technology, applied in the field of lasers, can solve the problems of long effective working distance, low conversion efficiency, and high pumping threshold, and achieve the effects of high damage threshold, high peak power, and lowering pumping threshold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

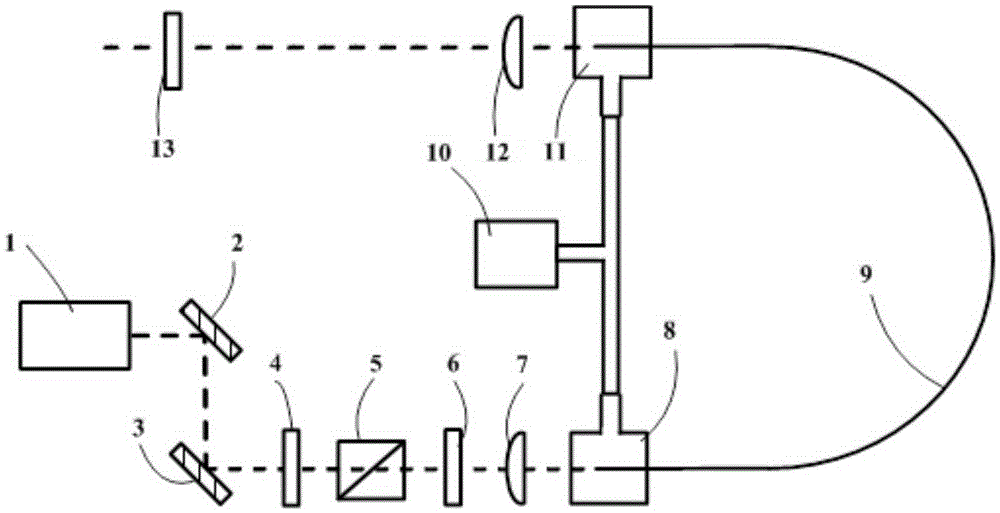

[0024] The accompanying drawings constituting a part of this application are used to provide further understanding of the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, and do not constitute an improper limitation of the present invention.

[0025] see figure 1 , the fiber gas laser generating device for generating 1.5 μm laser provided by the present invention includes: a pump source 1, a pump coupling device for coupling the pump laser light to a hollow-core photonic crystal fiber 9, a hollow-core photonic crystal fiber 9 and a quasi- Straight filtering device; the hollow photonic crystal fiber 9 is filled with working gas; the output end of the pump source 1 is optically connected to the input end of the pump coupling device, and the output end of the pump coupling device is optically connected to one end of the hollow photonic crystal fiber 9; The other end of the hollow-core photonic cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com