Seafood flavoring sauce and preparation method thereof

A seafood seasoning sauce and ingredient list technology, applied in food science and other directions, can solve the problems of difficult to control the production process, increase the company's production cost, labor-intensive product quality, etc., and achieve low production cost, convenient operation, and healthy eating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A seafood seasoning sauce made from the following components in mass percentage:

[0036] A bill of materials

[0037] serial number

raw material name

Unit (mass ratio%)

1

9.72

2

garlic

5.67

3

red onion

5.54

4

ginger

1.12

5

scallops

5.54

6

water

8.19

7

3.60

8

Fried Fish Mince

3.35

9

8.00

10

salt

2.94

11

6.73

12

White sugar

1.70

13

fructose syrup

4.00

14

10.00

15

Shredded Shrimp

1.12

16

soybean paste

16.76

Total:

93.98

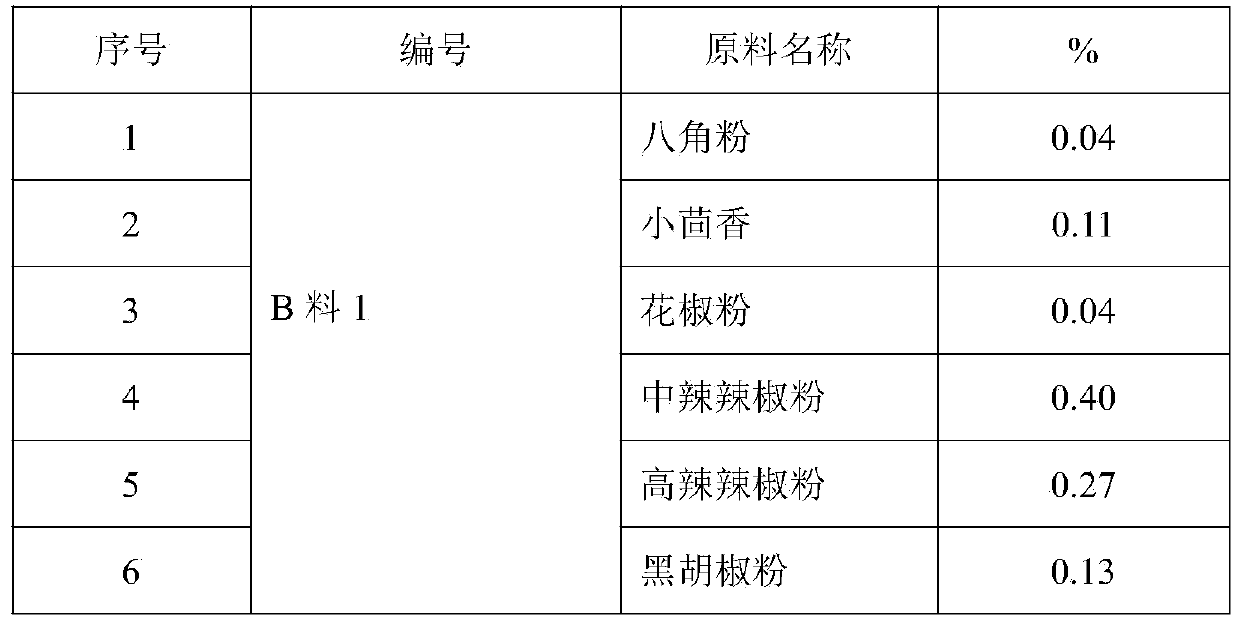

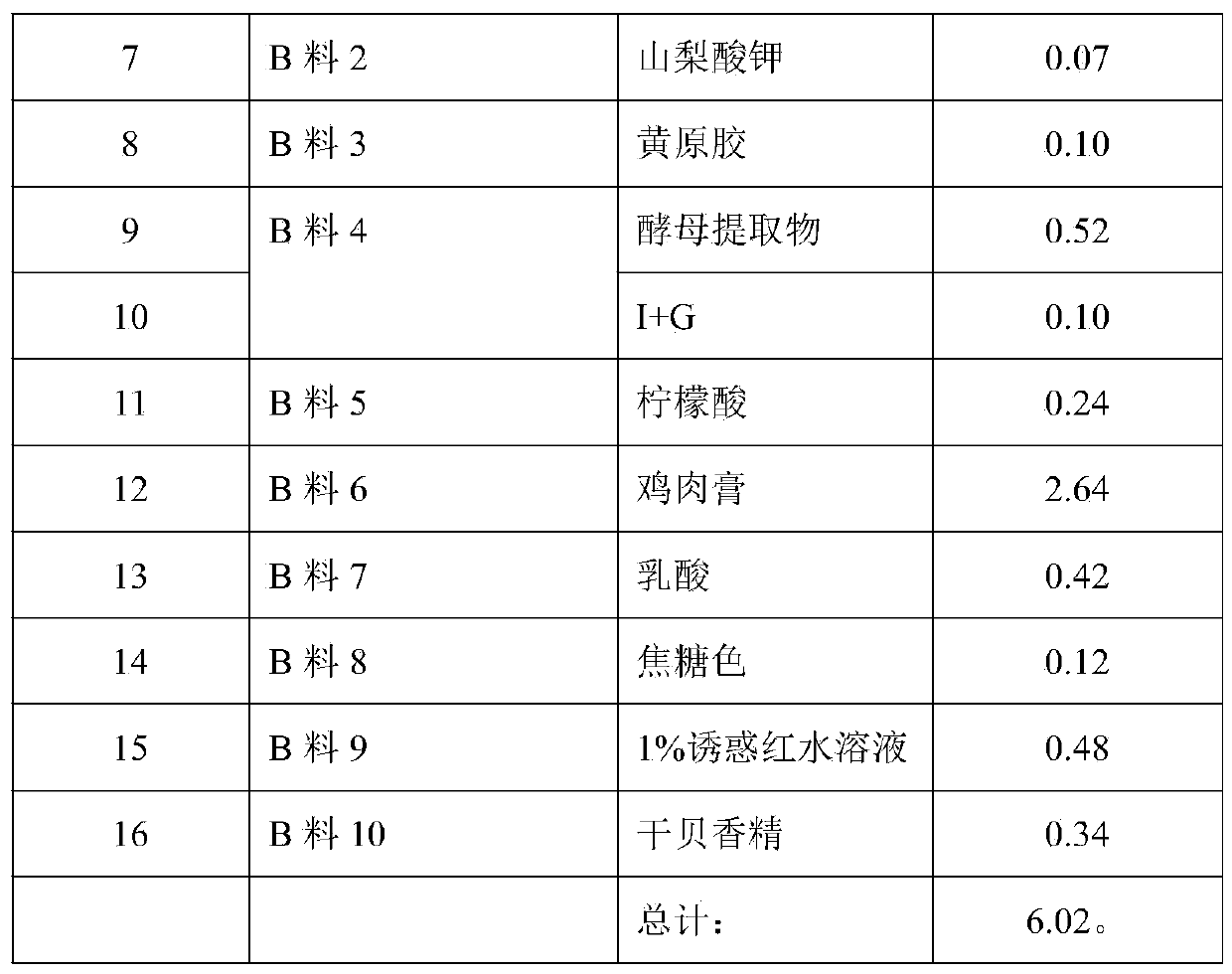

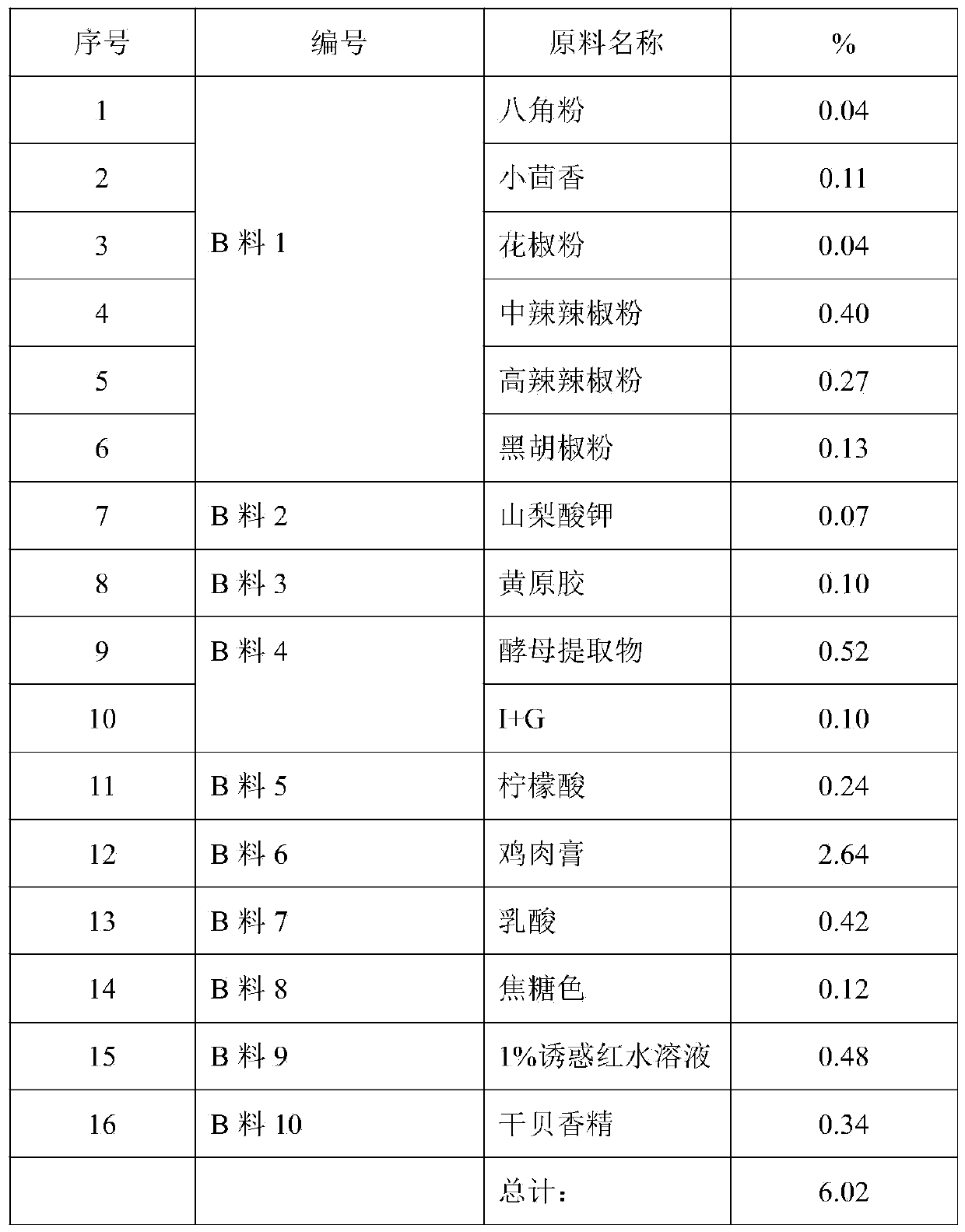

[0038] B bill of materials

[0039]

[0040]

[0041] The preparation method is as follows:

[0042] Step 1, Material A raw material handling and weighing:

[0043] 1) Peel and crush the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com