Low-temperature quick welding method for zirconia or zirconia-based composite materials

A zirconia-based, composite material technology, used in welding equipment, welding/welding/cutting items, resistance welding equipment, etc., and can solve problems such as low current/voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

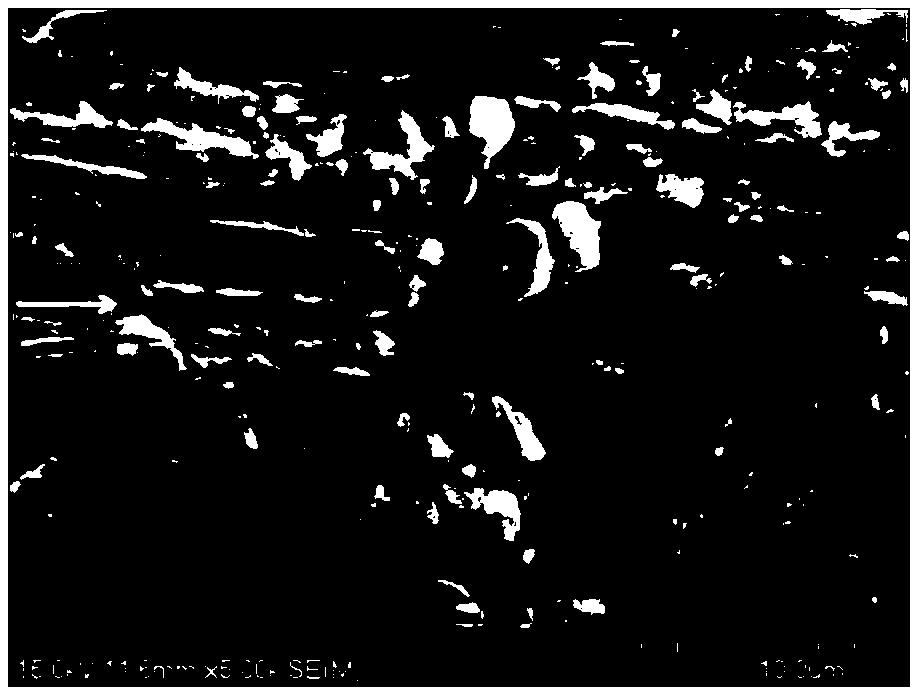

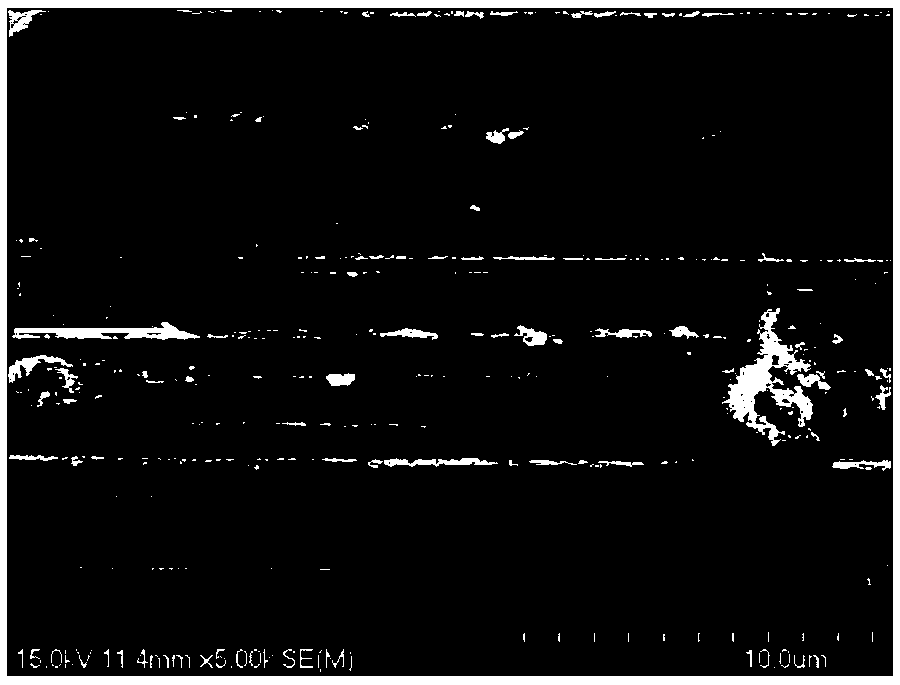

Image

Examples

Embodiment 1

[0023] Step 1: Polishing the surface of the sintered dense zirconia or zirconia-based composite material to below 1 μm;

[0024] Step 2: Closely stick the surfaces of zirconia or zirconia-based composite materials to be welded together, and apply a pressure of 3MPa, that is, the applied pressure is equal to the compressive strength multiplied by the welding area;

[0025] Step 3: Heating until the welding temperature is 700°C; the heating method adopts radiation heating, laser heating or sintering furnace heating, or other heating methods

[0026] Step 4: Apply a current density of 350mA / mm to the welded part 2 and keep it for 10 minutes to complete the welding of zirconia or zirconia-based composite materials; the current of the current density not less than the critical value is: the current density not less than the critical value multiplied by the area to be welded is equal to the applied during operation current value.

Embodiment 2

[0028] Step 1: Polishing the surface of the sintered dense zirconia or zirconia-based composite material to below 1 μm;

[0029] Step 2: Closely stick the surfaces of zirconia or zirconia-based composite materials to be welded together, and apply a pressure of 0.5 MPa, that is, the applied pressure is equal to the compressive strength multiplied by the welding area;

[0030] Step 3: Heating until the welding temperature is 700°C; the heating method adopts radiation heating, laser heating or sintering furnace heating, or other heating methods

[0031] Step 4: Apply a current density of 450mA / mm to the welded part 2 and keep it for 10 minutes to complete the welding of zirconia or zirconia-based composite materials; the current of the current density not less than the critical value is: the current density not less than the critical value multiplied by the area to be welded is equal to the applied during operation current value.

Embodiment 3

[0033] Step 1: Polishing the surface of the sintered dense zirconia or zirconia-based composite material to below 1 μm;

[0034] Step 2: Closely stick the surfaces of zirconia or zirconia-based composite materials to be welded together, and apply a pressure of 1 MPa, that is, the applied pressure is equal to the compressive strength multiplied by the welding area;

[0035] Step 3: heating until the welding temperature is 600°C; the heating method adopts radiation heating, laser heating or sintering furnace heating, or adopts other heating methods

[0036] Step 4: Apply a current density of 450mA / mm to the welded part 2 and keep it for 5 minutes to complete the welding of zirconia or zirconia-based composite materials; the current of the current density not less than the critical value is: the current density not less than the critical value multiplied by the area to be welded is equal to the applied during operation current value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com