Multi-rope cooperative control system testbed of ultradeep mine hoist

A mine hoist and collaborative control technology, which is applied in the fields of hoisting equipment, elevators, transportation and packaging in mines, can solve the problems of complex working conditions, difficult on-site testing of hoisting equipment, and restricting the development and utilization strategy of deep resources, etc. Easy maintenance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

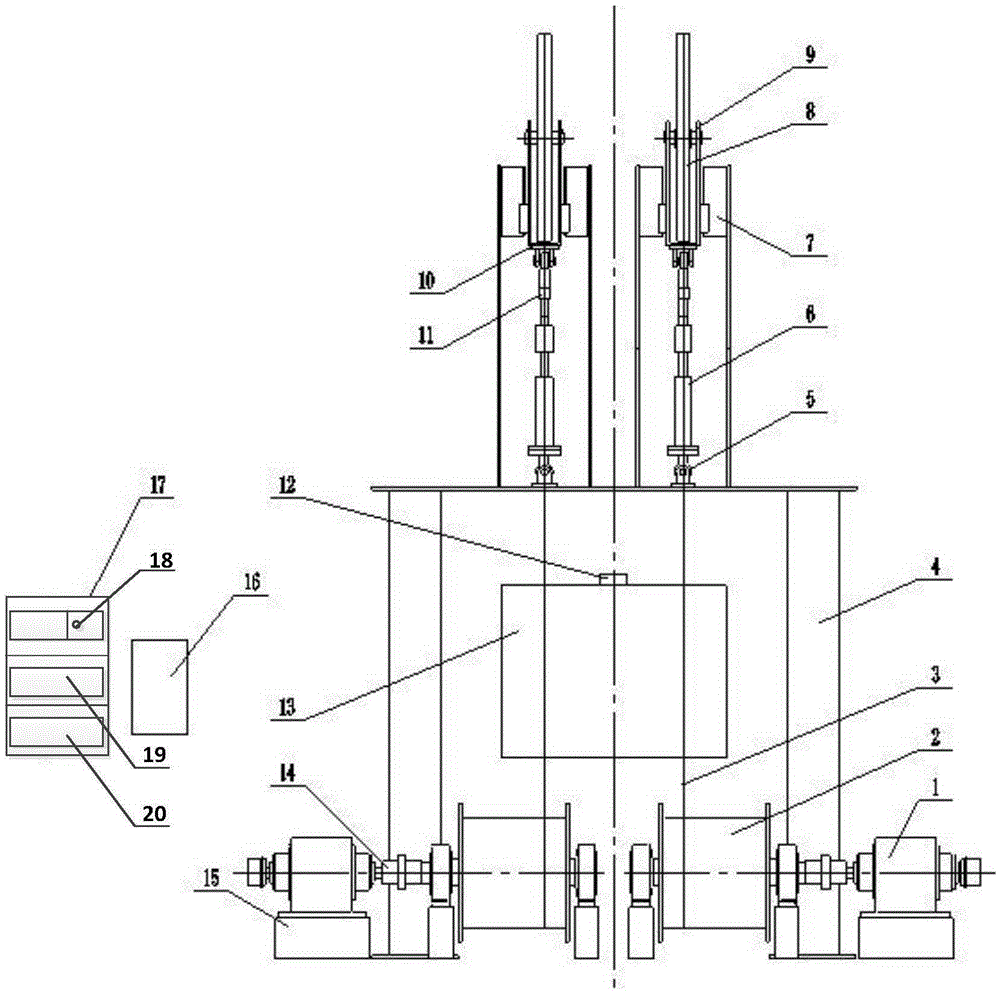

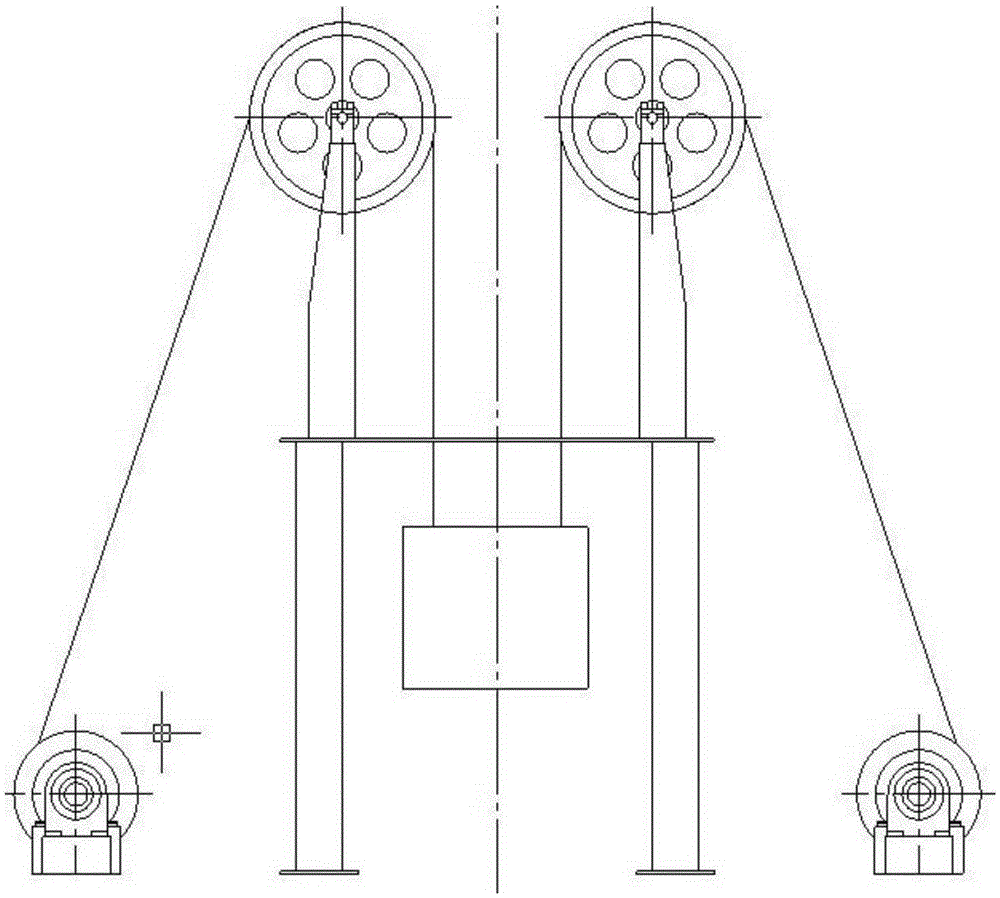

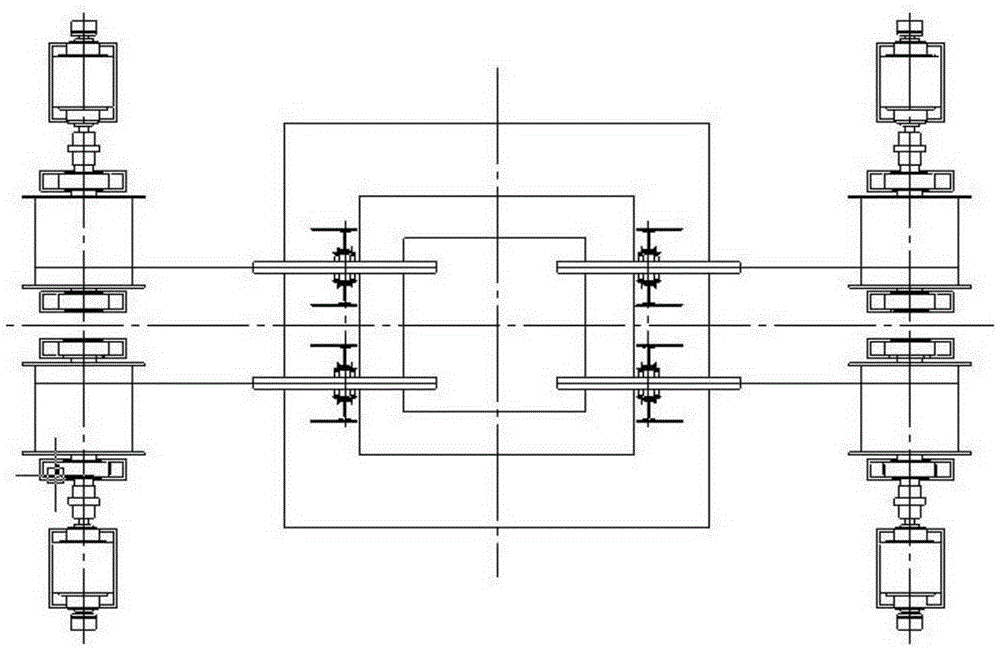

[0014] Example 1: figure 1 and figure 2 Among them, the control system test bench includes: four hydraulic motors 1 and corresponding four rollers 2 and four steel wire ropes 3, a set of steel structure supports 4, four hinges 5, four servo hydraulic cylinders 6, and four linear guide rails 7 , four skywheels 8, four skywheel brackets 9, four pressure sensors 10, four tension sensors 11, a gyrometer 12, a cage 13, four couplings 14, a motor base 15, and an oil pump 16;

[0015] The hydraulic motor 1 is connected to the drum 2 through a coupling 14. There is a steel wire rope 3 on the drum 2, and the steel wire rope 3 is connected to the cage 13; To the hinge 5, the upper end is connected with the sky wheel bracket 9, the sky wheel bracket 9 is connected with the sky wheel 8; the sky wheel bracket 9 is fixed on the linear guide rail 7, the hinge 5 and the linear guide rail 7 are connected on the steel structure bracket 4, and the servo The hydraulic cylinder 6 drives the sky...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com