Epoxy pouring sealant and preparation method thereof

A potting and epoxy technology, applied in the field of epoxy potting and its preparation, can solve the problems of toxic lead and zinc, brittle cement, etc., and achieve the effects of low curing exotherm, strong filling, and good impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

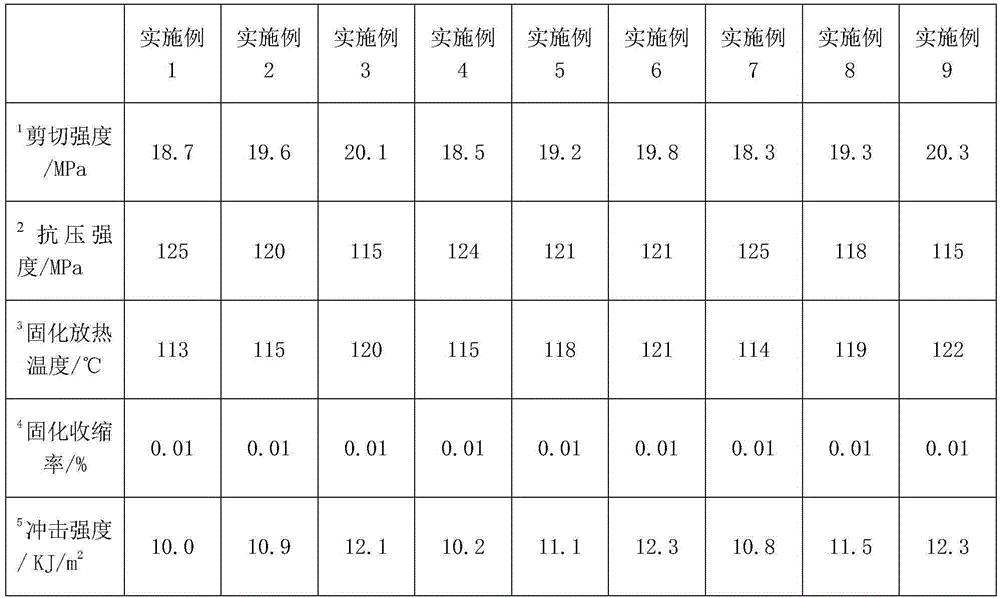

Examples

Embodiment 1

[0032] A component is made up of the following components by weight:

[0033] 16 parts of E-51 epoxy resin, 4 parts of bisphenol F epoxy resin, 2 parts of toughening agent, 3.0 parts of mixed diluent, 0.1 part of defoamer, 50 parts of spherical silica powder, and 0.05 part of fumed silica.

[0034] Component B is composed of the following components in middle parts:

[0035] Mixed amine epoxy curing agent 90 parts, epoxy accelerator 10 parts.

Embodiment 2

[0037] A component is made up of the following components by weight:

[0038] 12 parts of E-51 epoxy resin, 8 parts of bisphenol F epoxy resin, 5 parts of toughening agent, 2.0 parts of mixed diluent, 0.3 part of defoamer, 60 parts of spherical silica powder, and 0.08 part of fumed silica.

[0039] B component is made up of the component of following parts by weight:

[0040] Mixed amine epoxy curing agent 93 parts, epoxy accelerator 7 parts.

Embodiment 3

[0042] A component is made up of the following components by weight:

[0043] 10 parts of E-51 epoxy resin, 10 parts of bisphenol F epoxy resin, 10 parts of toughening agent, 1.5 parts of mixed diluent, 0.5 parts of defoamer, 70 parts of spherical silica powder, and 0.1 part of fumed silica.

[0044] B component is made up of the component of following parts by weight:

[0045] 96 parts of mixed amine epoxy curing agent, 4 parts of epoxy accelerator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com