Preparation method of high-temperature-resistant high-strength plugging agent for plugging oil and gas wells

A high-temperature-resistant and high-strength technology, used in the preparation of high-strength CANSEAL plugging agents, high-temperature resistance for leakage plugging, and water plugging in oil and gas wells. and other problems to achieve the effect of low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

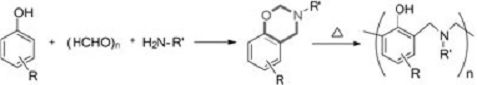

[0033] A method for preparing a high-temperature-resistant high-strength plugging agent for leak plugging and water plugging in oil and gas wells, comprising the following steps:

[0034] (1) Stir the polyoxymethylene and amine source at a molar ratio of 2.0: (0.9-1.1), then add the phenolic source at a molar ratio of phenolic hydroxyl group to amine group (0.8-1.1): 1.0, and reflux reaction at low temperature React for 6-10 hours. After the reaction, the product is washed with alkaline solution for 5-6 times, and then washed with deionized water to neutrality to obtain a low-viscosity, pure liquid main agent; the product has good fluidity, so that it can be easily pumped downhole Layers of water blocking and leak blocking;

[0035] The amine source can be selected from any one of diphenylmethanediamine, aniline, polyetheramine, allylamine, and 3-ethynylaniline or a combination of two or more. The phenol source can be selected from any one or combination of two or more of bi...

Embodiment 1

[0041] A method for preparing a high-temperature-resistant high-strength plugging agent for water and leakage plugging in oil and gas wells, comprising the following steps:

[0042] (1) Stir the polyoxymethylene and amine source at a molar ratio of 2.0: (0.9-1.1), then add the phenolic source at a molar ratio of phenolic hydroxyl group to amine group (0.8-1.1): 1.0, and reflux for 6-10 hour; after the reaction finishes, the product is washed 5-6 times with 30% sodium hydroxide aqueous solution alkali, and then washed to neutrality with deionized water to obtain low viscosity, pure liquid main agent; this product has good fluidity, making It can be easily pumped to the downhole water plugging and leak plugging intervals;

[0043] The amine source can be selected from any one of diphenylmethanediamine, aniline, polyetheramine, allylamine, and 3-ethynylaniline or a combination of two or more. The phenol source can be selected from any one or combination of two or more of bisphen...

Embodiment 2

[0049] A method for preparing a high-temperature-resistant high-strength plugging agent for water and leakage plugging in oil and gas wells, comprising the following steps:

[0050] (1) Stir the polyoxymethylene and amine source at a molar ratio of 2.0: (0.9-1.1), then add the phenolic source at a molar ratio of phenolic hydroxyl group to amine group (0.8-1.1): 1.0, and reflux for 6-10 hour; after the reaction finishes, the product is washed 5-6 times with 30% sodium hydroxide aqueous solution alkali, and then washed to neutrality with deionized water to obtain low viscosity, pure liquid main agent; this product has good fluidity, making It can be easily pumped to the downhole water plugging and leak plugging intervals;

[0051] The amine source can be selected from any one of diphenylmethanediamine, aniline, polyetheramine, allylamine, and 3-ethynylaniline or a combination of two or more. The phenol source can be selected from any one or combination of two or more of bisphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com