Matte external wall coating and preparation method thereof

An exterior wall coating and matte technology, applied in the direction of coating, etc., can solve the problems of decreased bonding protection, excessive emulsion, aging of exterior wall coatings, etc., and achieve the effect of reducing gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

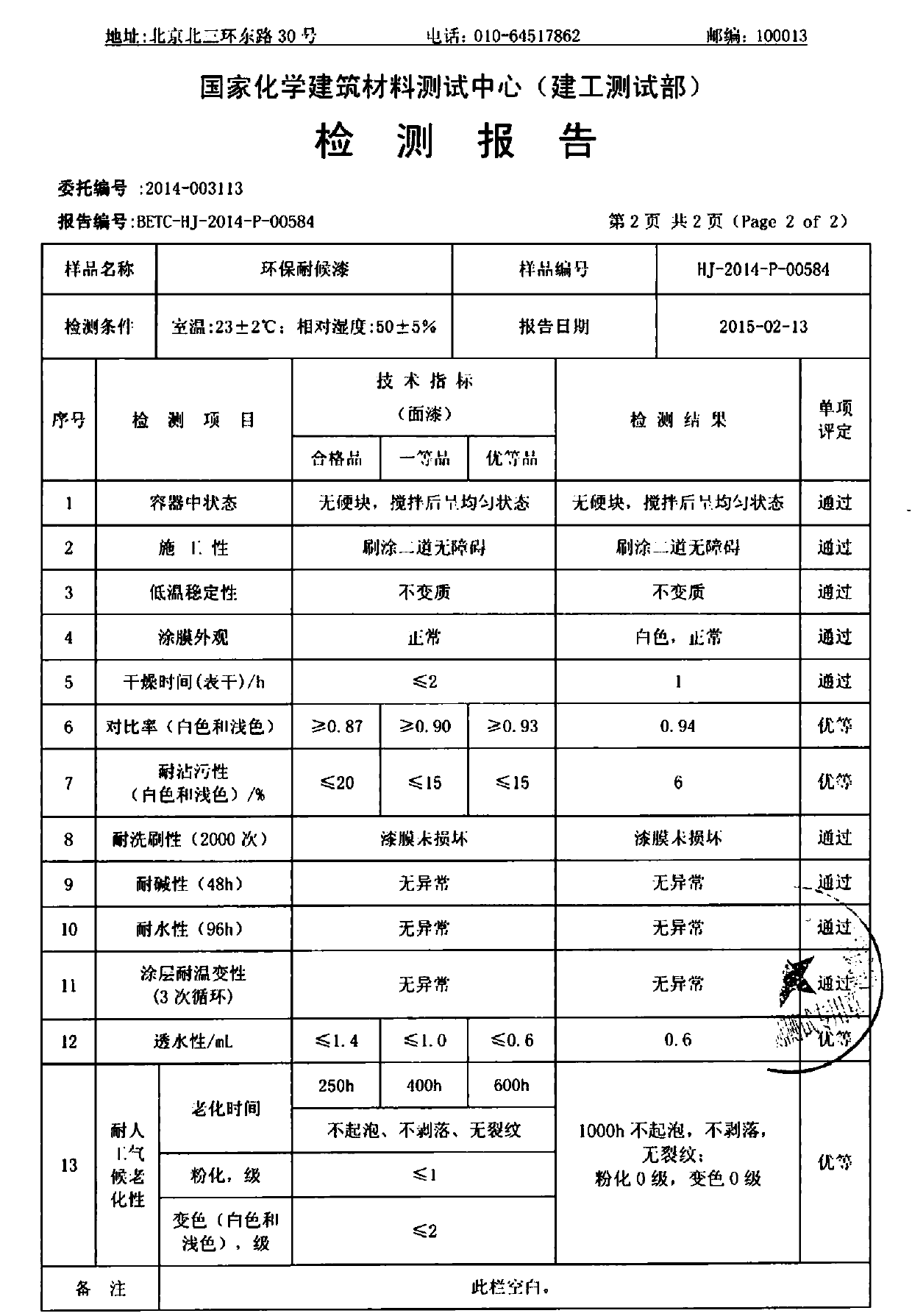

Examples

Embodiment 1

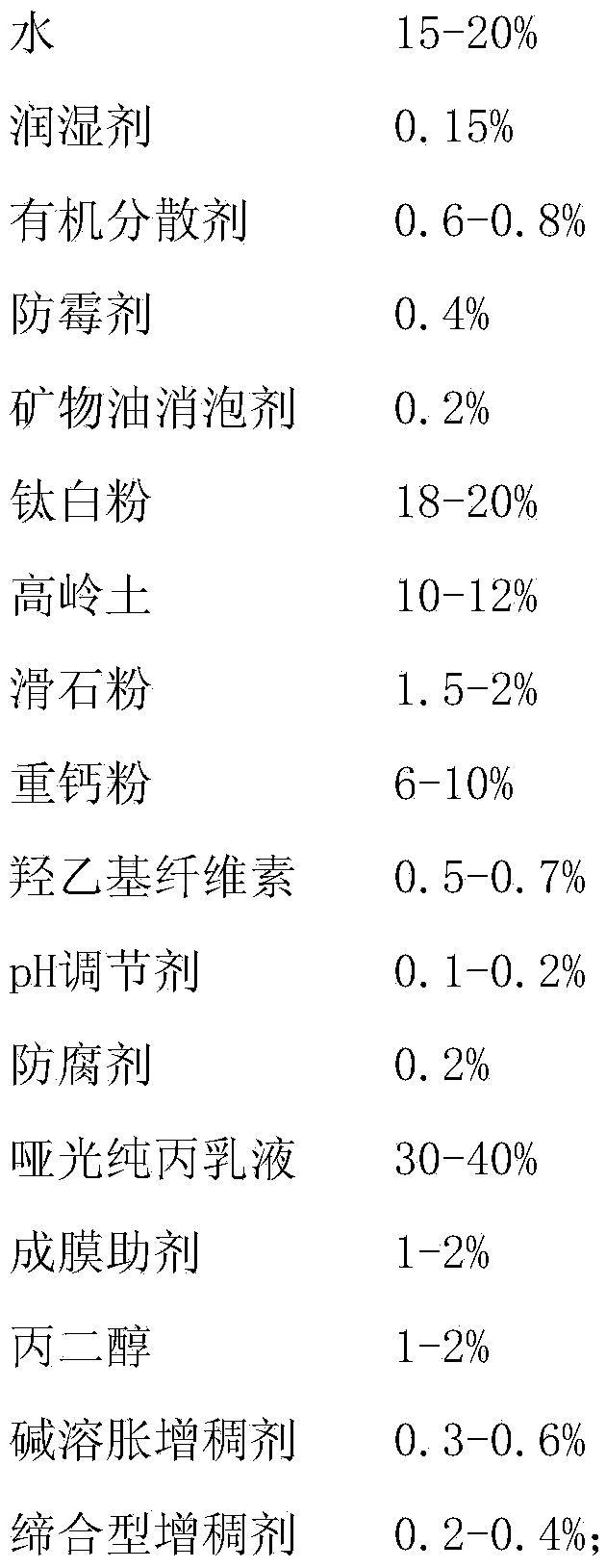

[0021] Present embodiment provides a kind of matte exterior wall paint, and this paint is made up of the following components by mass percentage:

[0022]

[0023] The preparation method of the coating is as follows: first, water, hydroxyethyl cellulose, organic dispersant, anti-mold agent, mineral oil defoamer accounting for 1 / 2 of the weight of the mineral oil defoamer, Add wetting agent, preservative and pH regulator into the dispersing tank, stir at a speed of 300-400rpm, then add rutile titanium dioxide (imported titanium dioxide can be used), kaolin (calcined kaolin can be used), talcum powder and Use heavy calcium powder to disperse the system at a speed of 1000-1500rpm to a fineness of ≤50μm, then add the remaining water, film-forming aids, propylene glycol and the remaining mineral oil defoamer, and then add matte pure acrylic emulsion (imported Matte pure acrylic emulsion), disperse at a low speed of 100-300rpm for 10 minutes until the system has no bubbles, and f...

Embodiment 2

[0025] Present embodiment provides a kind of matte exterior wall paint, and this paint is made up of the following components by mass percentage:

[0026]

[0027] The preparation method of the coating is as follows: the preparation method of the coating is as follows: first, water, hydroxyethyl cellulose, organic dispersant, antifungal agent, mineral oil defoamer accounting for 1 / 2 of the total weight of water Mineral oil defoamer, wetting agent, preservative and pH regulator are added to the dispersion tank, stirred at a speed of 300-400rpm, and then rutile titanium dioxide (imported titanium dioxide can be used), kaolin (can be used Calcined kaolin), talc powder and heavy calcium powder disperse the system to a fineness of ≤50μm at a speed of 1000-1500rpm, then add the remaining water, film-forming aids, propylene glycol and the remaining mineral oil defoamer, and then add matte Pure acrylic emulsion (imported matte pure acrylic emulsion can be used), disperse at a low s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com