Backward air inlet fuel cell stack

A fuel cell stack and back-to-back technology, applied in the directions of fuel cells, fuel cell additives, circuits, etc., can solve problems such as hazards, inability to support membrane electrode assemblies and seals, etc., to improve sealing reliability and reduce triggering. Possibility of safety accident, effect of high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

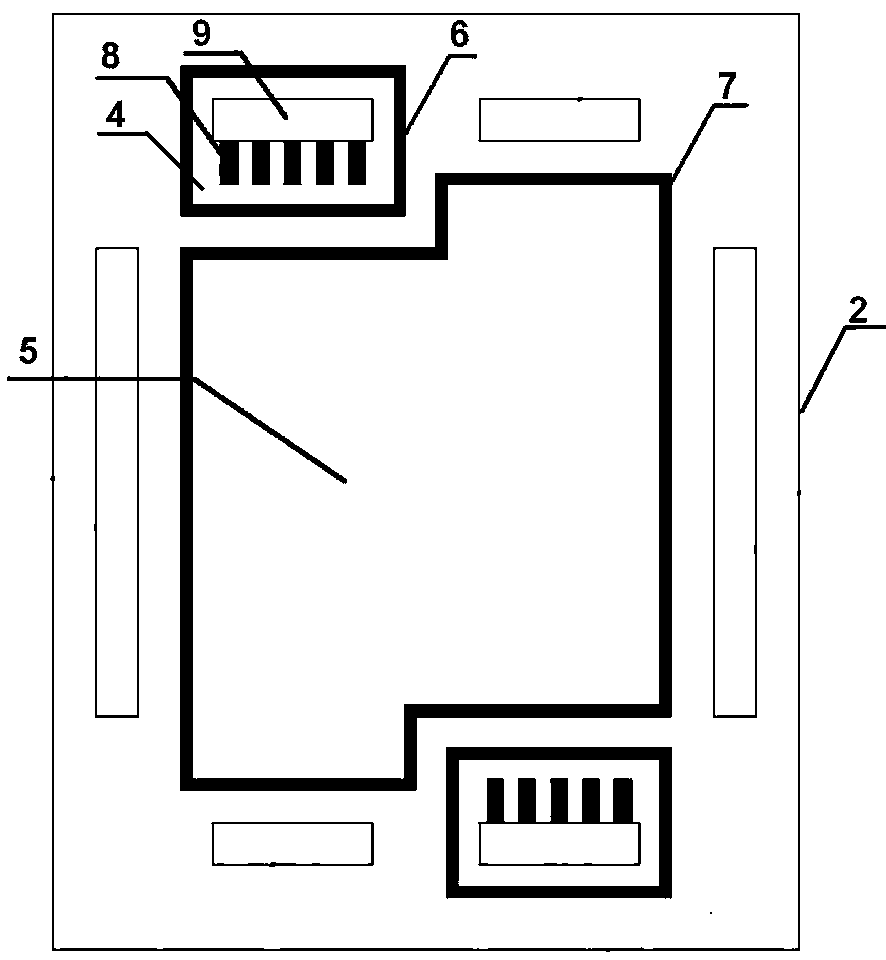

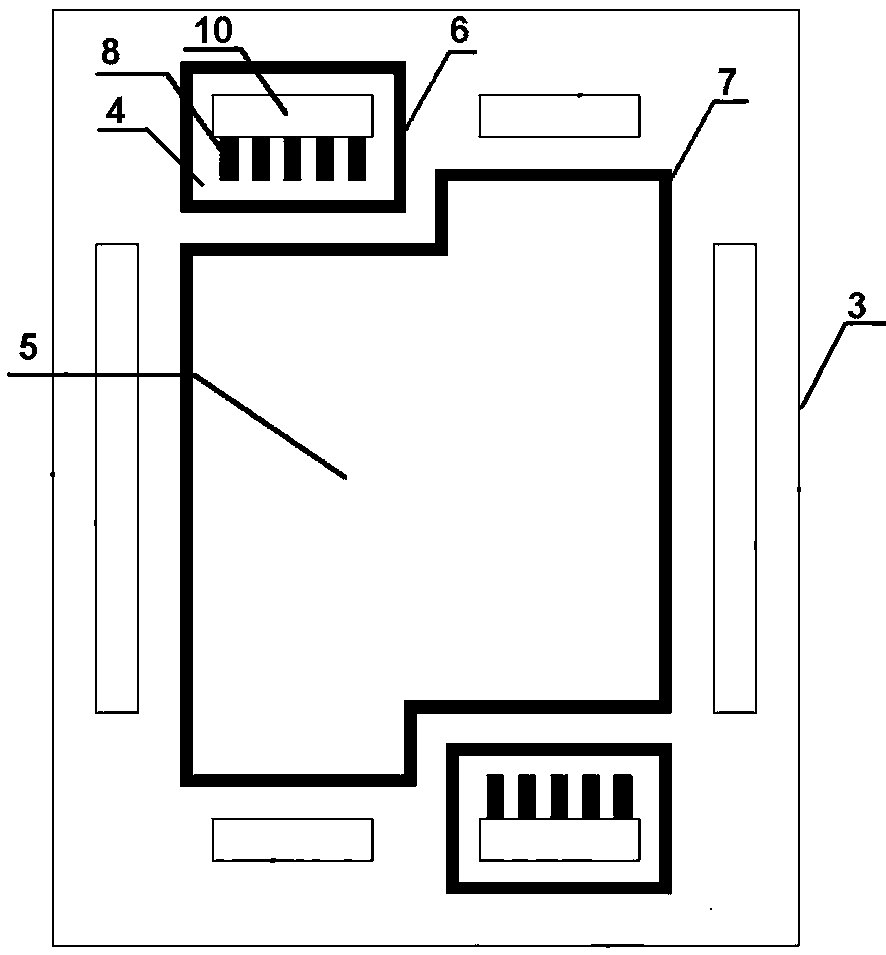

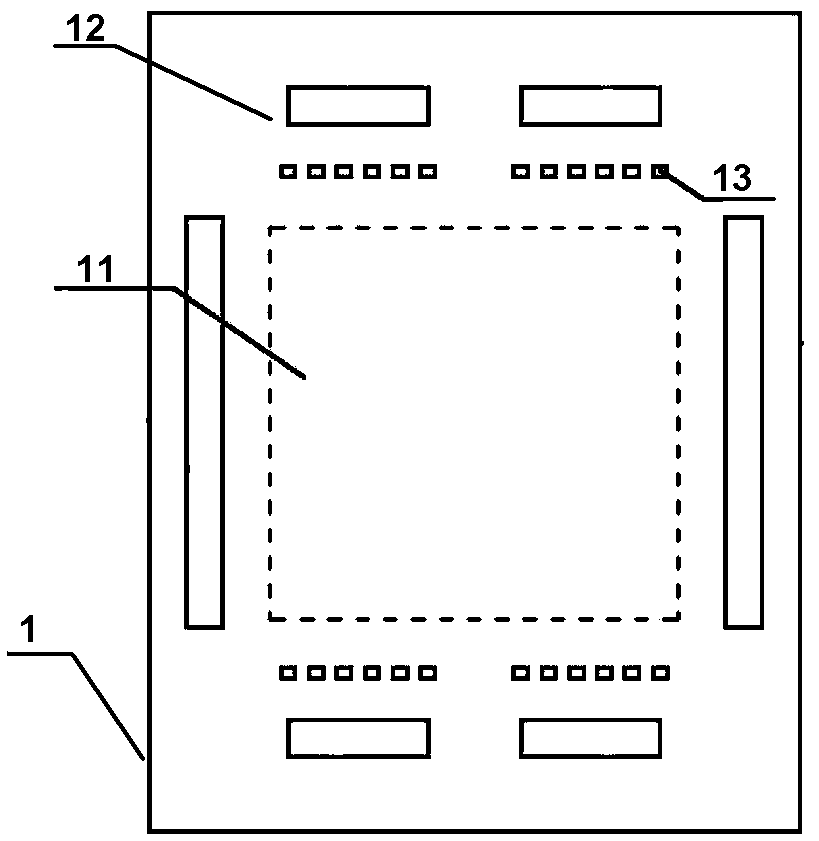

[0036] The fuel cell stack with back-to-air intake provided by the present invention, the components realizing its back-to-air intake function include an oxygen flow field plate 2 , a membrane electrode assembly 1 and a hydrogen flow field plate 3 arranged in close proximity to each other in sequence.

[0037] The oxygen flow field plate 2 includes two gas inlet and outlet sealing areas 4 and an active reaction sealing area 5 , the active reaction sealing area 5 is located between the gas inlet and outlet sealing bosses 6 and surrounded by the active reaction sealing bosses 7 . The closed area in the gas inlet and outlet closed boss 6 is provided with gas through holes and gas drainage points 8; the inside of the active reaction closed area 5 is a gas flow field, and the form of the flow field is not limited. See structurefigure 1 shown.

[0038] The structure of the hydrogen flow field plate 3 is consistent with that of the oxygen flow field plate 2, and the fronts of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com