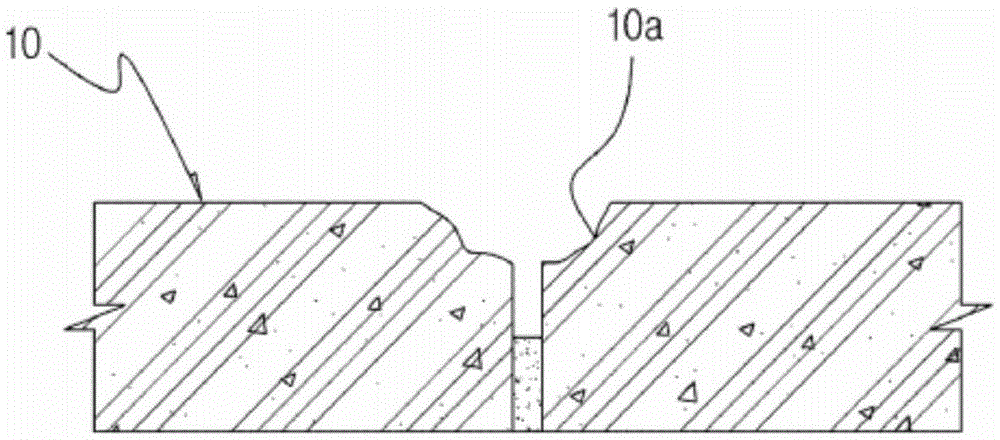

Method for repairing damaged part of expansion joint for concrete road

A concrete road and damage technology, applied in the direction of road repair, roads, roads, etc., can solve the problems of high maintenance cost, damage or peeling, short service life, etc., to shorten the repair construction time, prevent damage, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

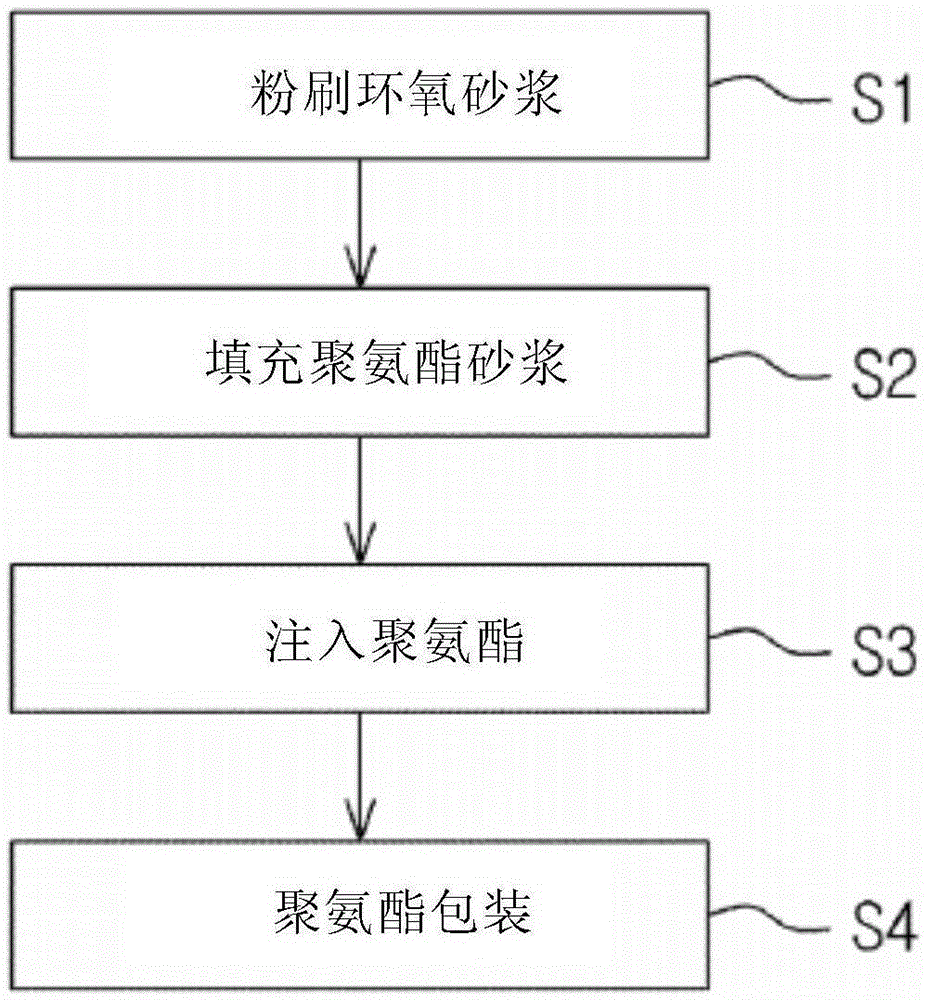

Method used

Image

Examples

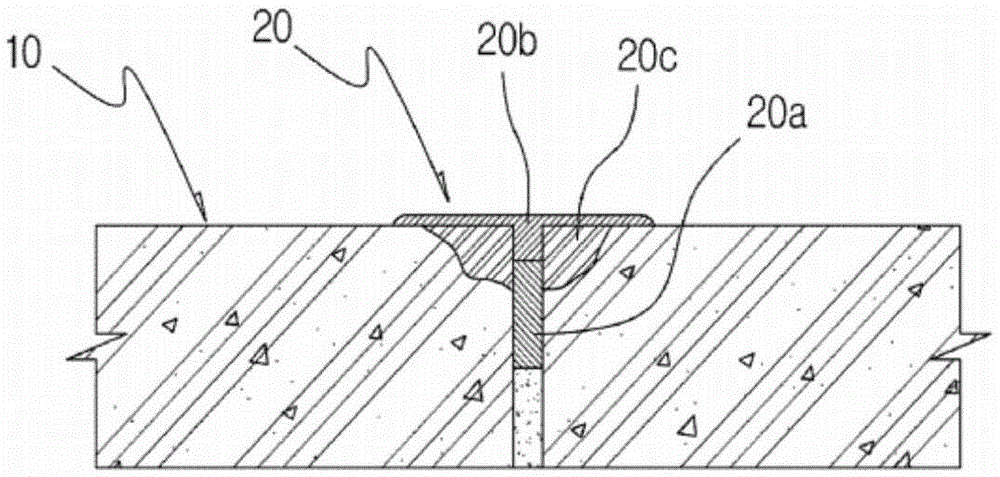

Embodiment

[0071] When making fast-hardening polyurethane mortar (20a), it is necessary to prepare a mixture of fast-hardening, high-strength, high-elastic polyurethane (accounting for 33% by volume), silica sand with a particle size of 20-100 mesh (accounting for 67% by volume), and fast-hardening polyurethane mortar (20a). Hard, high-strength, high-elastic polyurethane (20% by volume), polyurethane mortar mixed with silica sand with a particle size of 20-100 mesh (80% by volume), and fast-hardening, high-strength, high-elastic polyurethane . The fast-hardening, high-strength, high-elastic polyurethane (hereinafter referred to as the repair material joint) is formed into a plate shape and then hardened. Prepare a mixture of fast-hardening epoxy (33% by volume) and silica sand (67% by volume) with a particle size of 20 to 100 meshes, and mix them in proportion to form blocks of 50, 50, and 50 mm in length, width, and height. (hereinafter referred to as repairing material block) after ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| bond strength | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com