Fuel pump

A fuel pump and fuel technology, which is applied in the direction of fuel injection pump, pump, fuel injection device, etc., can solve the problems of high noise of fuel pump and loud collision sound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described below with reference to the drawings.

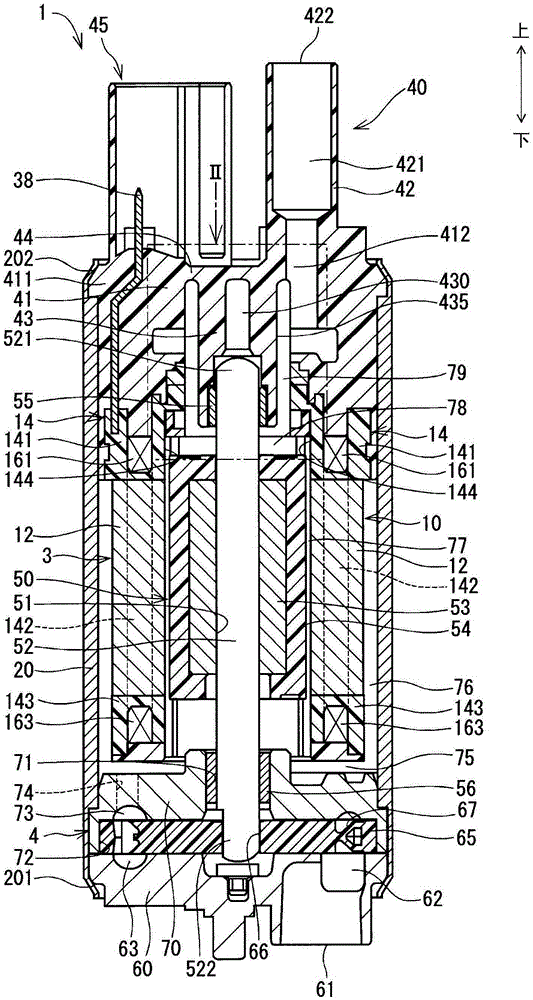

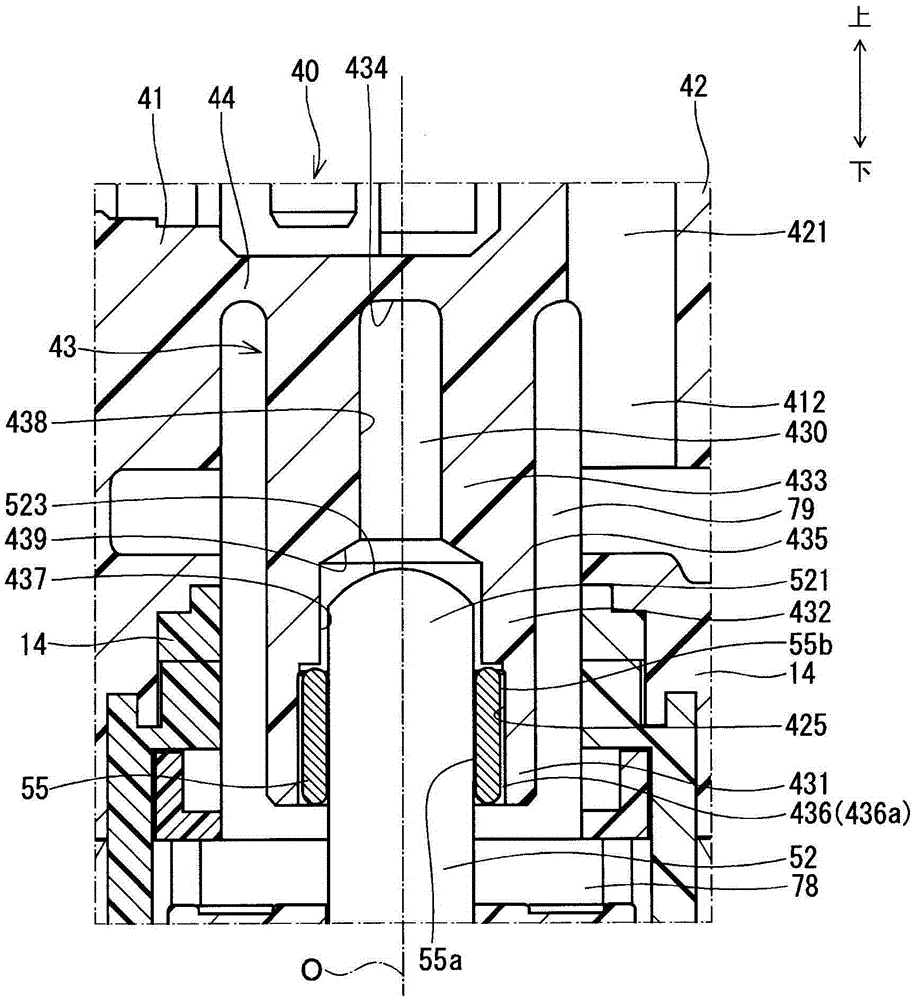

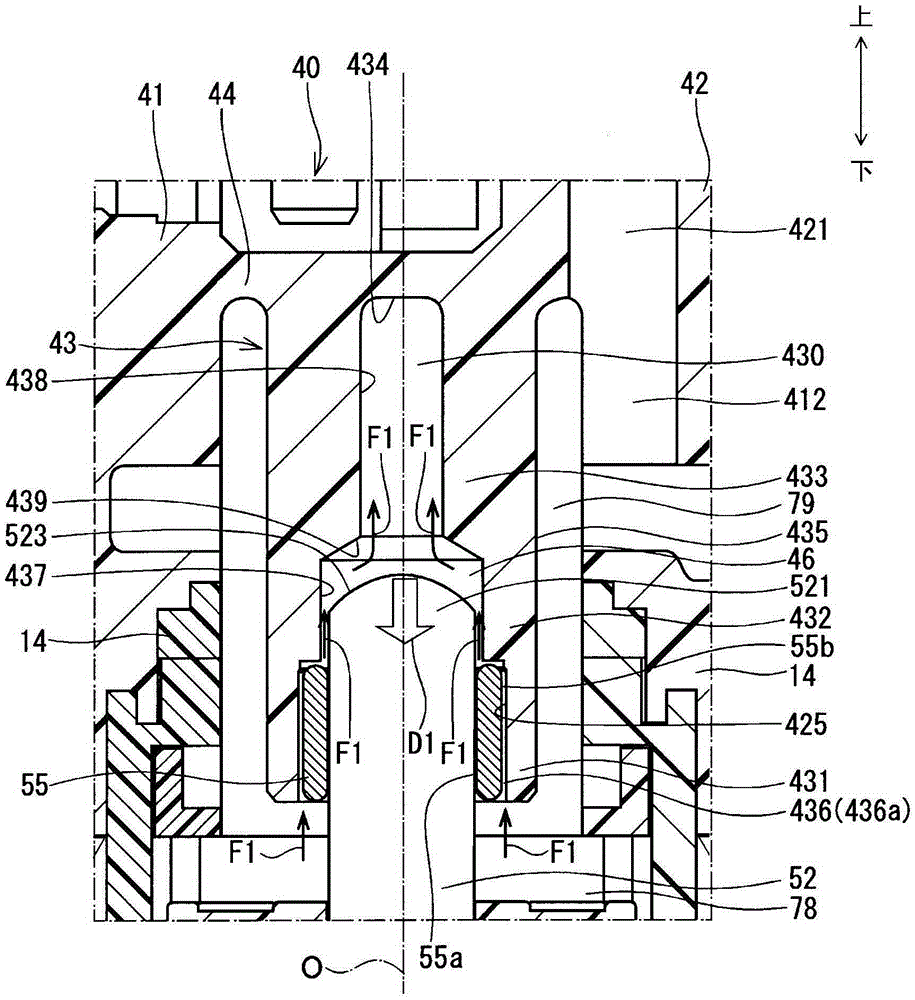

[0017] according to Figure 1 ~ Figure 4 A fuel pump according to one embodiment of the present invention will be described.

[0018] The fuel pump 1 includes a motor unit 3 , a pump unit 4 , a casing 20 , a pump cover 60 , a cover end 40 , and a bearing housing 43 . In the fuel pump 1 , the motor unit 3 and the pump unit 4 are accommodated in a space formed by the housing 20 , the pump cover 60 and the cover end 40 . fuel pump 1 from figure 1 The suction port 61 shown on the lower side sucks the fuel in the fuel tank not shown, and figure 1 The discharge port 422 shown on the upper side of , discharges to the internal combustion engine. In addition, in Figure 1~4 , let the upper side be "upper side" and the lower side be "lower side".

[0019] The casing 20 is formed in a cylindrical shape from metal such as iron.

[0020] The pump cover 60 closes the end 201 of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com