Process method improving quality of Yinqiu tea

A process method and technology of silver ball tea, applied in the field of tea processing, can solve the problems of unstable temperature, unsanitary fire temperature, easy to produce mildew, etc., and achieve the appearance of non-yellowing, long storage time, and not easy to mildew. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Baking method of the present invention:

[0014] (1) Preheating: use the Wuyuandou roaster to heat for 30 minutes, and the temperature of the roaster is 75-85 degrees;

[0015] (2) Baking: Put the formed silver ball tea into the bucket pan for baking, keep the temperature at 85-95 degrees, then put the bucket pan into the hot air outlet of the blower, and replace the front and rear bucket pans every 8-12 minutes And roll the silver ball tea in the bucket tray, and recirculate the silver ball tea for 3-4 hours;

[0016] (3) Titian: Pour the dried Yinqiu tea from the bucket pan into the sieve of the Yuandou tea roaster for baking. The baking time is 10-12 minutes and the temperature is 115-125 degrees.

Embodiment 2

[0018] Self-built brick-concrete baking method:

[0019] The bottom of the drying room is composed of a fire stove, a fire ditch and a fire wall. The fire ditch is covered with a pot cover, and coal is used as fuel. There are two moisture-discharging air holes on the top. After the temperature rises, the heat will be dissipated through the pot cover and the fire wall. A thermometer is hung in the drying room. The interior is welded with steel bars or angle steel. -20cm. When the temperature in the drying room reaches above 60 degrees after the fire is raised, pour silver ball tea into the sieve and put the sieve into the drying room to bake at a temperature of 60-80 degrees. The upper and lower layers of the sieve are exchanged every 30-40 minutes Turn the silver ball tea in the sieve to make it bake evenly. After baking for 6-8 hours, take out the silver ball tea and put it in the drying room to enhance the fragrance and make the finished product.

Embodiment 3

[0021] Cabinet type electric control baking method:

[0022] Pour the silver ball tea into the sieve and put the sieve into the roaster, adjust the temperature to 80-100 degrees, and bake for 4-6 hours. After the silver ball tea is dried, pour it into the roaster to enhance the aroma and bake The temperature is 95-105 degrees, and the baking time is 25-35 minutes.

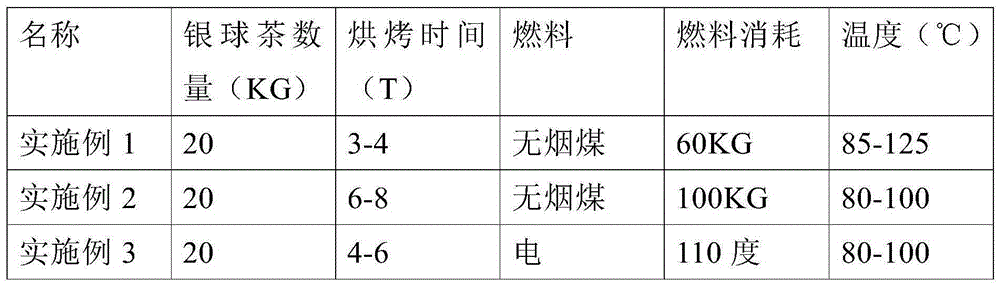

[0023] Table 1 is the finished product contrast data of embodiment 1 and embodiment 2 and embodiment 3:

[0024]

[0025] The test results in Table 1 show that the baking time required by Example 1 is short, the fuel is less, and the cost is low.

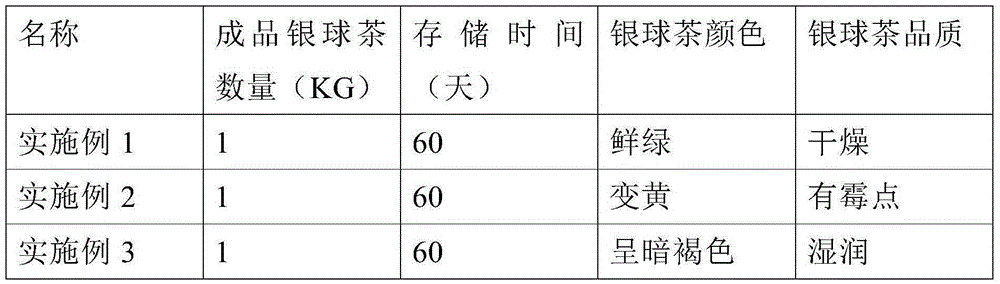

[0026] Table 2 is the storage comparison data of the finished Yinqiu tea in Example 1, Example 2 and Example 3:

[0027]

[0028] The test results in Table 2 show that the silver ball tea baked in Example 1 has a long storage time and is not easy to deteriorate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com