Dry method denitration system for coke oven smoke

A coke oven and flue gas technology is applied in the field of dry denitration system of coke oven flue gas, which can solve the problems of complex system process, large amount of waste water, secondary pollution, etc., so as to ensure denitration efficiency, save energy, and reduce effluent concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

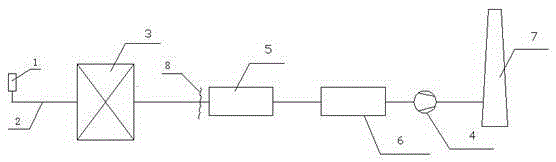

[0024] A dry denitrification system for coke oven flue gas, comprising a dry powder injector 1, an intake flue 2, a coke oven 3, an SCR denitrification reactor 5, a boiler 6, and a chimney 7; the dry powder injector 1 is arranged in the inlet At the entrance of the gas flue 2, the intake flue 2 is connected to the coke oven 3, and the coke oven 3 is provided with an exhaust flue, and the exhaust flue is connected to the SCR denitration reactor 5, and the SCR denitration reactor 5 The exhaust port of the boiler is connected to the air inlet of the boiler 6, and the exhaust port of the boiler 6 is connected to the chimney 7.

Embodiment 2

[0026] A dry denitrification system for coke oven flue gas, comprising a dry powder injector 1, an intake flue 2, a coke oven 3, an SCR denitrification reactor 5, a boiler 6, and a chimney 7; the dry powder injector 1 is arranged in the inlet At the entrance of the gas flue 2, the intake flue 2 is connected to the coke oven 3, and the coke oven 3 is provided with an exhaust flue, and the exhaust flue is connected to the SCR denitration reactor 5, and the SCR denitration reactor 5 The exhaust port of the boiler is connected to the air inlet of the boiler 6, and the exhaust port of the boiler 6 is connected to the chimney 7.

[0027] The exhaust port of the boiler 6 is provided with an induced draft fan 4 .

Embodiment 3

[0029] A dry denitrification system for coke oven flue gas, comprising a dry powder injector 1, an intake flue 2, a coke oven 3, an SCR denitrification reactor 5, a boiler 6, and a chimney 7; the dry powder injector 1 is arranged in the inlet At the entrance of the gas flue 2, the intake flue 2 is connected to the coke oven 3, and the coke oven 3 is provided with an exhaust flue, and the exhaust flue is connected to the SCR denitration reactor 5, and the SCR denitration reactor 5 The exhaust port of the boiler is connected to the air inlet of the boiler 6, and the exhaust port of the boiler 6 is connected to the chimney 7.

[0030] The exhaust port of the boiler 6 is provided with an induced draft fan 4 .

[0031] An ammonia injection grid 8 is arranged between the coke oven 3 and the SCR denitration reactor 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com