Crude benzene tubular furnace tail gas cleaning system and process

A tube furnace and crude benzene technology, which is applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems affecting the environmental protection emission and use of the coke oven system of the gas purification system, and the low temperature of the tail gas of the crude benzene tube furnace. , the problem of high initial investment and operating costs, to achieve the effect of reducing one-time investment, simple structure and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

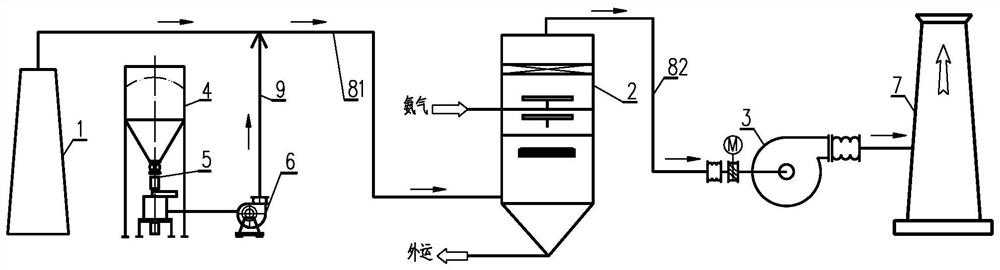

[0037] like figure 1 As shown, a crude benzene tube furnace tail gas cleaning system includes a desulfurizer device, a dust removal and denitrification integrated device 2 and a chimney 7 . The crude benzene tube furnace 1 is connected to the dust removal and denitrification integrated device 2 through the first flue gas pipeline 81, and the desulfurizer device is connected to the first flue gas pipeline 81 through the desulfurizer delivery pipeline 9, and the desulfurizer delivery pipeline 9 is provided with a desulfurizer The conveying fan 6; the dust removal and denitrification integrated device is connected to the chimney 7 through the second flue gas pipe 82, and the induced draft fan 3 is arranged on the second flue gas pipe 82.

[0038] The desulfurizer device includes a desulfurizer powder bin 4 and a mill 5 , and the mill 5 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com