1, 4-bis(chloromethyl)benzene synthesis technology

A synthesis process, the technology of p-dichlorobenzyl, applied in the direction of organic chemistry, preparation of halogenated hydrocarbons, chemical instruments and methods, etc., can solve the problems of low product conversion rate and high cost, and achieve high yield, low cost and good dissolution effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

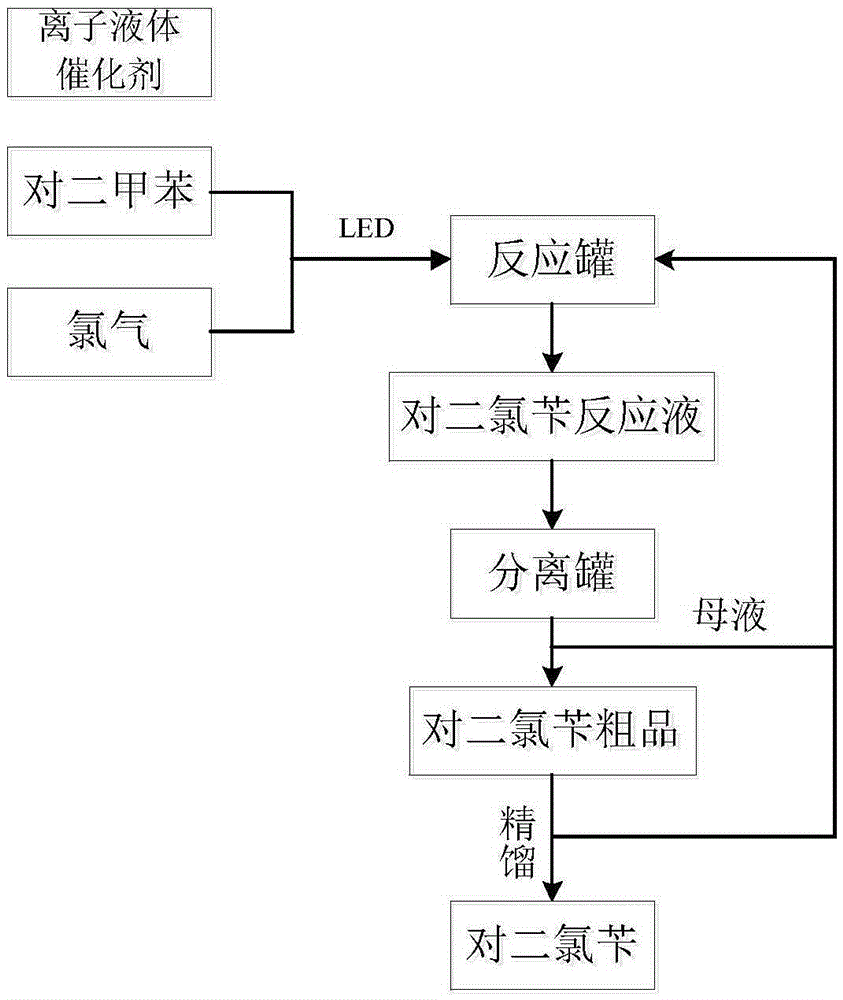

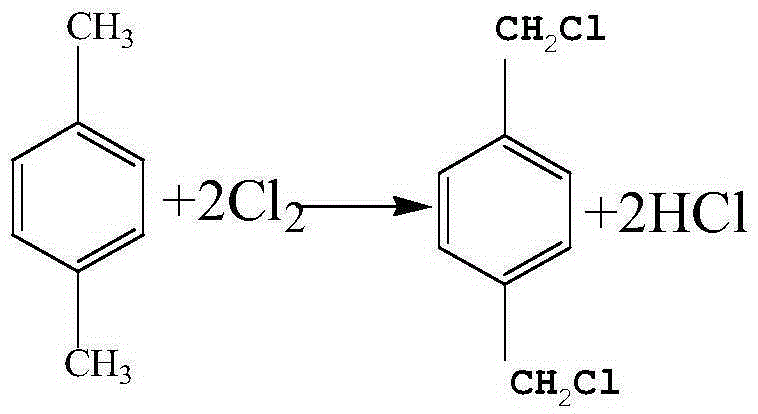

[0028] The synthetic technique of p-dichlorobenzyl is as follows:

[0029] (1) Reaction:

[0030] Add 100g of p-xylene and 0.1g of 1-dodecyl-3-methylimidazolium chloride salt into the reaction tank, pass 173.9g of chlorine gas under the irradiation of LED light source, react at 110°C for 10h, and obtain the content of p-dichlorobenzyl: 70wt% p-dichlorobenzyl reaction solution;

[0031] (2) Separation:

[0032] Add the p-dichlorobenzyl reaction solution into the separation tank, carry out layering treatment at 90°C, return the upper layer solution to the reaction tank to continue the reaction, and the lower layer solution is the crude p-dichlorobenzyl;

[0033] (3) Refined:

[0034] Put the crude p-dichlorobenzyl into the rectification tower, conduct vacuum distillation at 8mmHg, collect 150-155°C fractions, and obtain 116.60g p-dichlorobenzyl with a content of 99% and a melting point of 98.5-100.9°C.

Embodiment 2

[0036] The synthetic technique of p-dichlorobenzyl is as follows:

[0037] (1) Reaction:

[0038] Add 100g of p-xylene and 0.2g of 1-dodecyl-3-methylimidazolium chloride salt into the reaction tank, pass 200.6g of chlorine gas under the irradiation of LED light source, and react at 115°C for 6h, and the content of p-dichlorobenzyl is 75wt% p-dichlorobenzyl reaction solution;

[0039] (2) Separation:

[0040] Add the p-dichlorobenzyl reaction solution into the separation tank, carry out layering treatment at 85°C, return the upper layer solution to the reaction tank to continue the reaction, and the lower layer solution is the crude p-dichlorobenzyl;

[0041] (3) Refined:

[0042] Put the crude p-dichlorobenzyl into the rectification tower, carry out vacuum distillation at 8mmHg, collect 150-155°C fractions, and obtain 124.86g p-dichlorobenzyl with a content of 99.05% and a melting point of 99.1-100.6°C.

Embodiment 3

[0044] The synthetic technique of p-dichlorobenzyl is as follows:

[0045] (1) Reaction:

[0046] Add 100g of p-xylene and 0.5g of 1-butyl-2,3-methylimidazolium chloride salt into the reaction tank, pass 267.5g of chlorine gas under the irradiation of LED light source, and react at 120°C for 3 hours to obtain the content of p-dichlorobenzyl Be 80wt% p-dichlorobenzyl reaction solution;

[0047] (2) Separation:

[0048] Add the p-dichlorobenzyl reaction liquid from the overflow port of the reaction tank to the separation tank, and carry out layering treatment at 80°C, return the upper layer solution to the reaction tank to continue the reaction, and the lower layer solution is the crude p-dichlorobenzyl;

[0049] (3) Refined:

[0050] Put the crude p-dichlorobenzyl into the rectification tower, carry out vacuum distillation under the pressure of 8mmHg, collect the 150-155°C fraction, and obtain 133.12g p-dichlorobenzyl, the content is 99.1%, and the melting point is 99.5-100....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com