Two-component high-tear-resistance liquid silicone rubber for mold production, and preparation method thereof

A liquid silicone rubber, two-component technology, used in the field of two-component high tear-resistant liquid silicone rubber for molding and its preparation, can solve the problems of poor leveling, hardening, and brittleness, and achieve good flow The effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

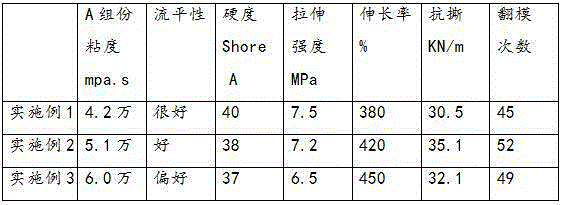

Examples

Embodiment 1

[0033] A two-component high-tear-resistant liquid silicone rubber for molding according to an embodiment of the present invention includes the following components by weight:

[0034] Component A:

[0035] Vinyl-terminated polydimethylsiloxane: 100 parts;

[0036] (ViMe 2 SiO(Me 2 SiO) a SiMe 2 Vi where a=550, viscosity 8000mpa.s)

[0037] Terminal chain and side chain high vinyl polydimethylsiloxane: 5 parts;

[0038] (ViMe 2 SiO(Me 2 SiO) b (MeViSiO) c SiMe 2 Vi, where b=700, c=50, viscosity 16000mpa.s)

[0039] Terminal hydroxyl side chain vinyl polydimethylsiloxane: 15 parts;

[0040] (HOME 2 SiO((Me 2 SiO) e (MeViSiO) f SiMe 2 OH, where e=100, f=3, viscosity 1000mpa.s)

[0041] Fumed silica: 30 parts;

[0042] (with a surface area of 200m 2 / g)

[0043] Catalyst: 0.6 parts;

[0044] (H 2 PtCl 6 THF solution 2000ppm)

[0045] Component A materials are made by the following steps:

[0046]Put 100 parts of vinyl polydimethylsiloxane with a viscosi...

Embodiment 2

[0061] A two-component high-tear-resistant liquid silicone rubber for molding according to an embodiment of the present invention includes the following components by weight:

[0062] A component material:

[0063] Vinyl-terminated polydimethylsiloxane: 100 parts;

[0064] (ViMe 2 SiO(Me 2 SiO) a SiMe 2 Vi, where a=600, viscosity 10000mpa.s)

[0065] Terminal chain and side chain high vinyl polydimethylsiloxane: 10 parts;

[0066] (ViMe 2 SiO(Me 2 SiO) b (MeViSiO) c SiMe 2 Vi, where b=750, c=75, viscosity 20000mpa.s)

[0067] Terminal hydroxyl side chain vinyl polydimethylsiloxane: 20 parts;

[0068] (HOME 2 SiO((Me 2 SiO) e (MeViSiO) f SiMe 2 OH, where e=150, f=6, viscosity 2000mpa.s)

[0069] Fumed silica: 38 parts;

[0070] (with a surface area of 300m 2 / g)

[0071] Catalyst: 1.0 parts;

[0072] (H 2 PtCl 6 THF solution / Pt[(ViMe2Si)2O]2=1:12500ppm)

[0073] Component A materials are made by the following steps:

[0074] Put 100 parts of vinyl po...

Embodiment 3

[0087] A two-component high-tear-resistant liquid silicone rubber for molding according to an embodiment of the present invention includes the following components by weight:

[0088] Component A:

[0089] Vinyl-terminated polydimethylsiloxane: 100 parts;

[0090] (ViMe 2 SiO(Me 2 SiO) a SiMe 2 Vi, where a=650, viscosity 12000mpa.s)

[0091] Terminal chain and side chain high vinyl polydimethylsiloxane: 15 parts;

[0092] (ViMe 2 SiO(Me 2 SiO) b (MeViSiO) c SiMe 2 Vi, where b=800, c=100, viscosity 24000mpa.s)

[0093] Terminal hydroxyl side chain vinyl polydimethylsiloxane: 25 parts;

[0094] (HOME 2 SiO((Me 2 SiO) e (MeViSiO) f SiMe 2 OH, where e=200, f=8, viscosity 3000mpa.s)

[0095] Fumed silica: 45 parts;

[0096] (with a surface area of 380m 2 / g)

[0097] Catalyst: 1.4 parts;

[0098] (Pt[(ViMe 2 Si) 2 O] 2 3000ppm)

[0099] Component A materials are made by the following steps:

[0100]Put 100 parts of vinyl polydimethylsiloxane with a visc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com