Muffling device and electromechanical device

A technology for noise reduction devices and electromechanical equipment, which is applied in the field of electromechanical equipment and noise reduction devices, which can solve problems such as limited use, fading, corrosion, etc., and achieve the effects of improving usage conditions, widening audio bandwidth, and widening application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049]On the one hand, this embodiment provides a noise reduction device, which is used in electromechanical equipment that is prone to noise (such as air conditioning equipment) to eliminate the noise generated when the working parts in the electromechanical equipment are running, so as to improve people's life or life. Work creates a better environment.

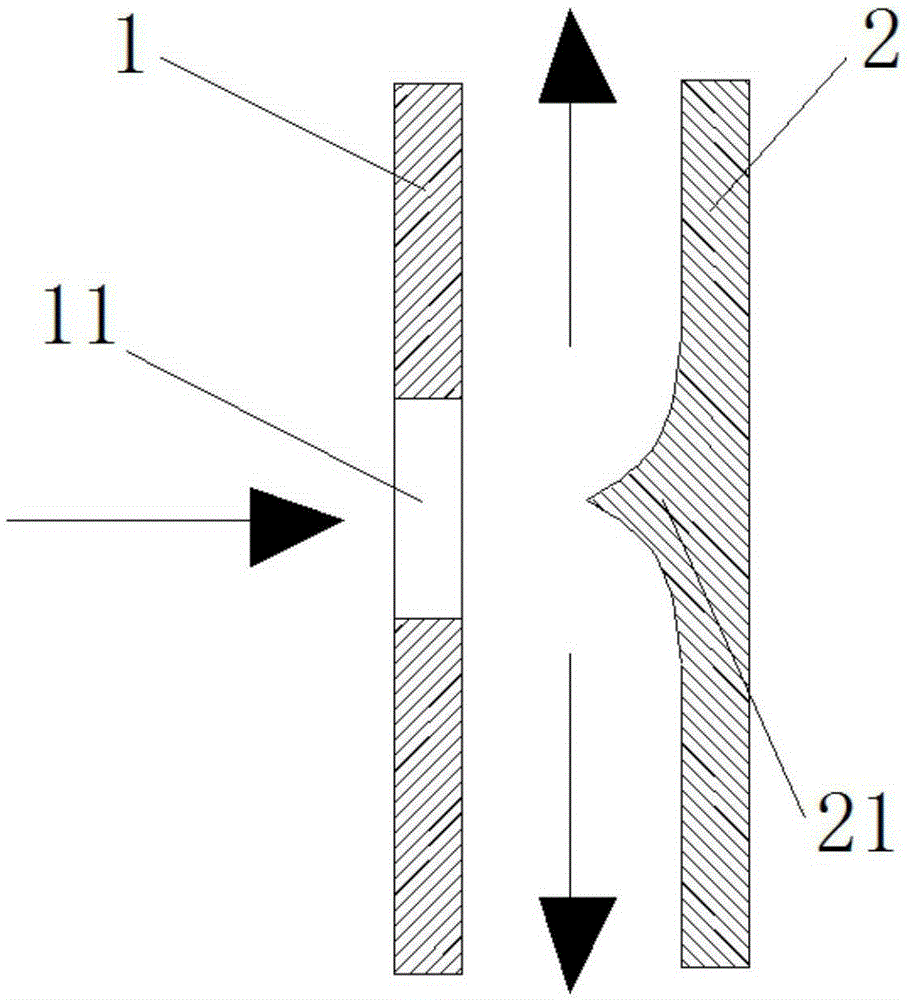

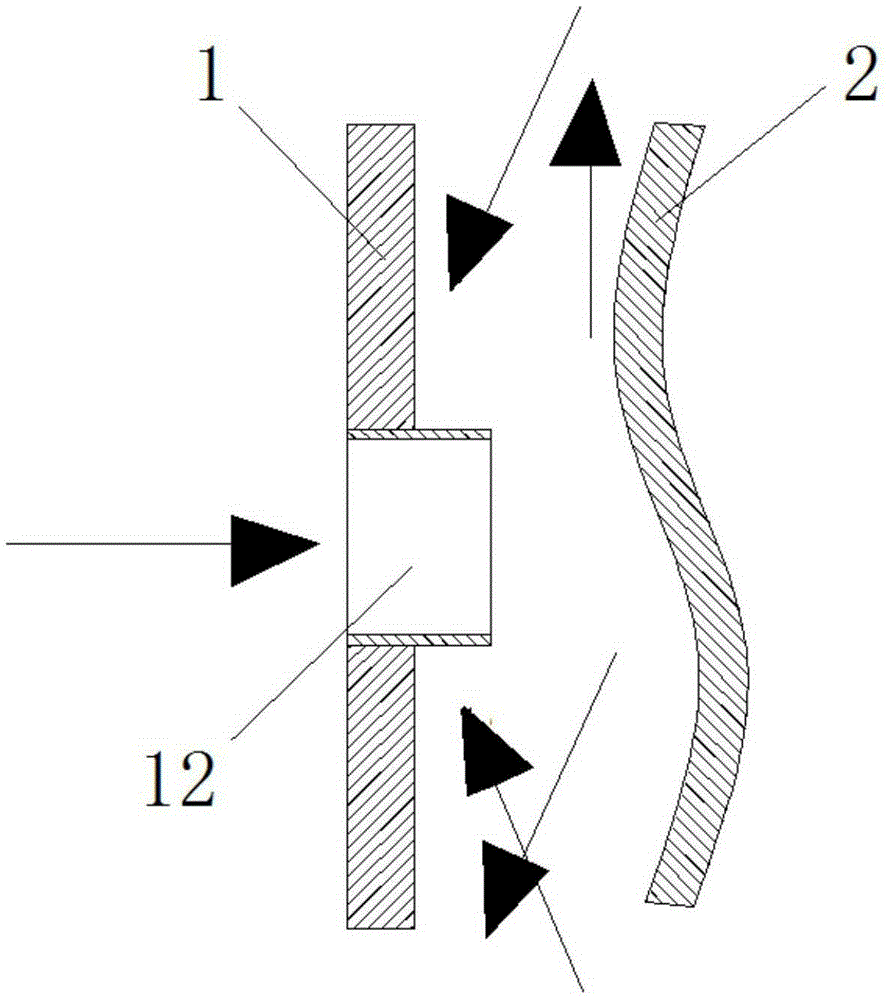

[0050] Specifically, such as figure 1 and figure 2 As shown, the muffler is a closed cavity structure. Wherein, the noise reduction device includes a first side plate 1 and a second side plate 2 . Wherein, the first side plate 1 is provided with a plurality of holes 11 . The second side plate 2 is arranged opposite to the first side plate 1; and the second side plate 2 and the first side plate 1 form two opposite side walls of the airtight cavity. Wherein, the plurality of holes 11 on the first side plate 1 are used to allow beam-shaped sound waves to enter the airtight cavity through the small holes. Wherein, the sec...

Embodiment 2

[0056] Preferably, this embodiment provides a noise reduction device, compared with Embodiment 1, such as figure 1 As shown, the second side plate 2 of the noise reduction device in this embodiment includes a second side plate body and a sound guide part 21 . Wherein, the second side plate body is a flat plate structure. The number of the sound guides 21 is consistent with the number of the holes 11 , and they are arranged at positions corresponding to the holes 11 on the second side plate body. Wherein, the sound guide part 21 is used to change the propagation direction of the beam-shaped sound wave vertically entering the small hole, so that it can diverge and propagate along the direction of the plane where the second side plate body is located, and finally make the sound wave travel along the plane where the second side plate body is located. Under the damping action of the "air cushion spring" in the direction, it is gradually converted into internal energy and dissipate...

Embodiment 3

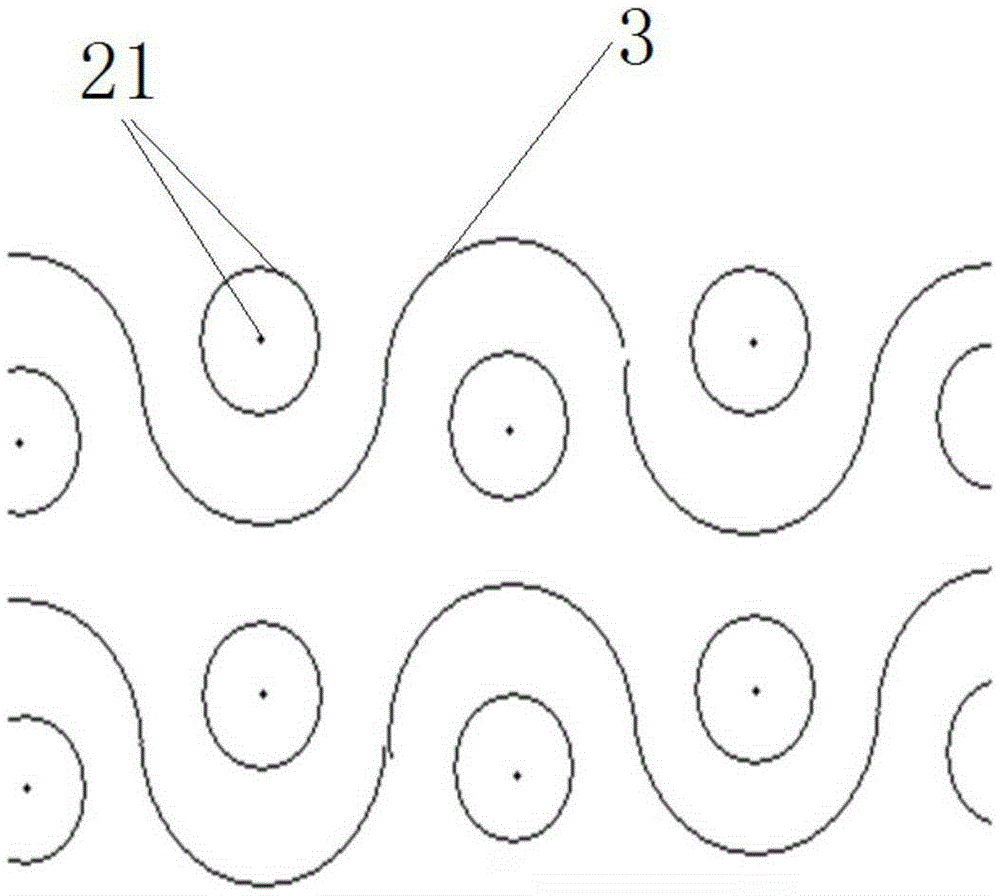

[0062] Preferably, this embodiment provides a noise reduction device, compared with Embodiment 2, such as figure 1 As shown, the sound guide part 21 in this embodiment has a first end and a second end opposite to each other. Wherein, the first end of the sound guide part 21 is arranged on the second side plate 2 , and the second end of the sound guide part 21 is arranged to point to the tip of the corresponding hole 11 .

[0063] Preferably, the sound guide part 21 is a cone structure, and the generatrix of the cone is a curve, and the curve is preferably a parabola, so as to better convert the sound wave vertically incident into the cavity from the hole 11 into the sound wave along the second side plate body. Sound waves that spread out in a plane. Wherein, the first end of the sound guiding part 21 is the bottom surface of the cone structure, and the second end of the sound guiding part 21 is the top of the cone structure.

[0064] The sound-absorbing device provided in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com