A kind of effluent cream and its preparation method

A technology for producing water cream and liquid oil, applied in the field of daily chemicals, can solve the problems of uneven stability, product peeling, etc., and achieve the effect of remarkable use effect, excellent heat resistance stability, and soft and comfortable skin feel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A method for preparing the water-discharging cream according to the present invention includes: a step of mixing components of the water-discharging cream.

[0043] According to the preparation method of effluent cream of the present invention, comprises the following steps:

[0044] (1) Add deionized water, humectant, and inorganic salt into the water phase stirring pot, stir and heat to 80-85°C to dissolve completely, and obtain the water phase liquid substance.

[0045] (2) Add liquid oil, oil-phase thickener, oil-soluble preservative, and emulsifier into the oil-phase stirring pot, stir and heat to 80-85° C. to dissolve completely, and obtain the oil-phase liquid substance.

[0046] (3) Pump the oil phase liquid substance into the emulsification pot, then pump the water phase liquid substance into the emulsification pot, and then add liquid oil, (polydimethylsiloxane (and) polydimethylsiloxane / Vinyl polydimethylsiloxane crosslinked polymer) was stirred and mixed u...

Embodiment 1-4

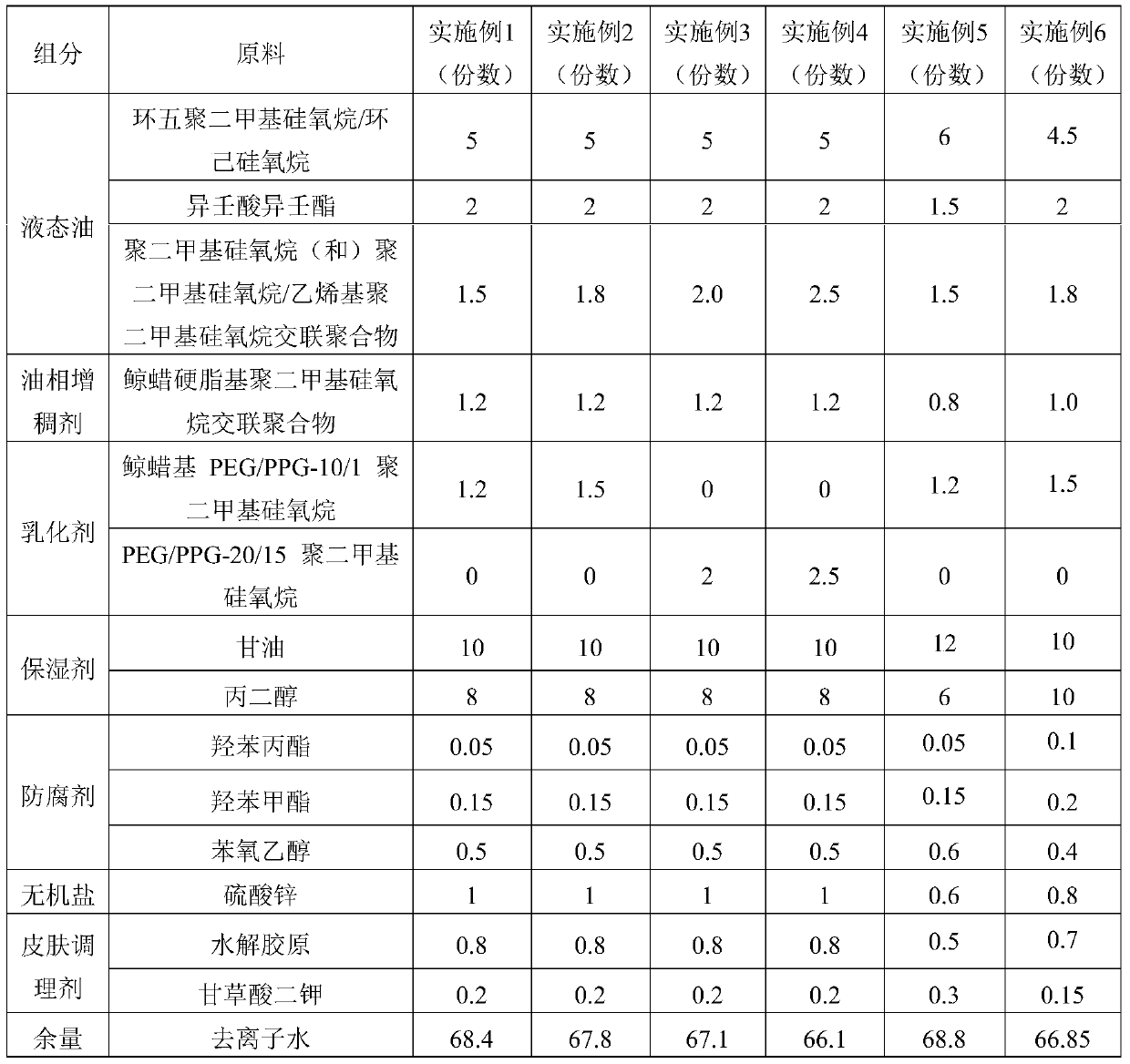

[0052] According to the content (number of parts) of each component of Examples 1-6 in the following Table 1, and according to the following steps, water-emitting creams I-VI were prepared.

[0053] The method for preparing water-out cream I-VI is as follows:

[0054] (1) Add deionized water, humectant (glycerin, propylene glycol) and inorganic salt (magnesium sulfate) into the water phase stirring pot, stir and heat to 80°C to dissolve completely, and obtain the water phase liquid substance.

[0055] (2) Combine liquid oil (cyclopentamethicone / cyclohexasiloxane, isononyl isononanoate), oil phase thickener (cetaryl dimethicone cross polymer), oil-soluble preservatives (propylparaben, methylparaben), emulsifiers (cetyl PEG / PPG-10 / 1 polydimethylsiloxane, PEG / PPG-20 / 15 polymethicone Dimethylsiloxane) was added into the oil phase stirring pot, stirred and heated to 80°C to dissolve completely, and the oil phase liquid substance was obtained.

[0056] (3) Pump the oil phase liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com