Special numerical control automatic drilling machine for tire mold

A technology for tire molds and drilling machines, which is applied in the directions of boring/drilling, drilling/drilling equipment, manufacturing tools, etc., which can solve the problems of large tire mold volume, heavy workload, and high labor intensity, and achieve improved Effect of degree of automation and work efficiency, improved accuracy and consistency, good process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

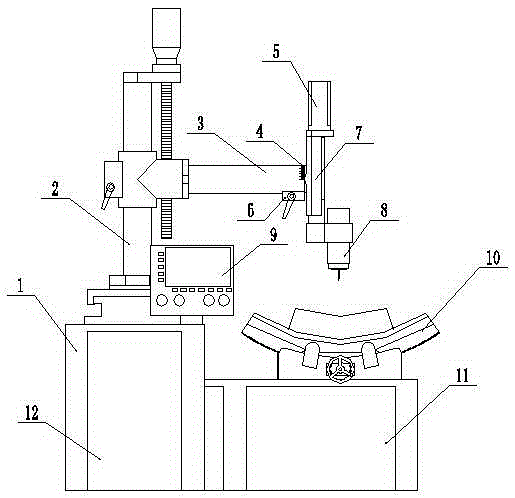

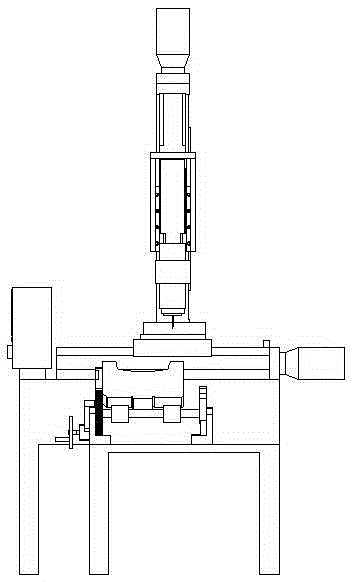

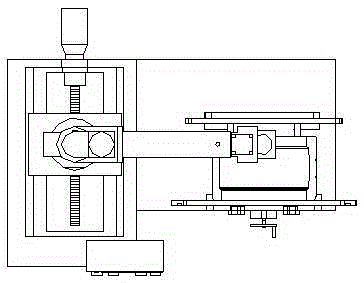

[0025] Such as figure 1 , 2 , 3, a tire mold dedicated CNC automatic drilling machine of the present invention includes a base 1, an electric control room 12 is arranged in the base 1, and a digital control panel 9 is arranged on the base 1. Electrical equipment is arranged in the electric control room 12, and the work of the whole drilling machine is controlled by a digital control panel 9. A workbench 11 is arranged on one side of the base 1, a tooling fixture 10 is arranged on the top of the workbench 11, a column 2 that can translate back and forth is vertically arranged above the base 1, and a cantilever 3 that can be lifted and lowered along the column 2 is arranged horizontally on the column 2. 3. The end is rotatably connected with a rotating arm 7 which can rotate around the transverse central axis of the cantilever 3. When the rotating arm 7 rotates to a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com