Stamping and welding formation method for BFe 30-1-1 iron white copper small curvature radius elbow

A forming method, stamping welding technology, applied in the field of stamping welding forming, can solve problems such as wrinkles and fractures, and achieve the effects of easy operation, energy saving, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

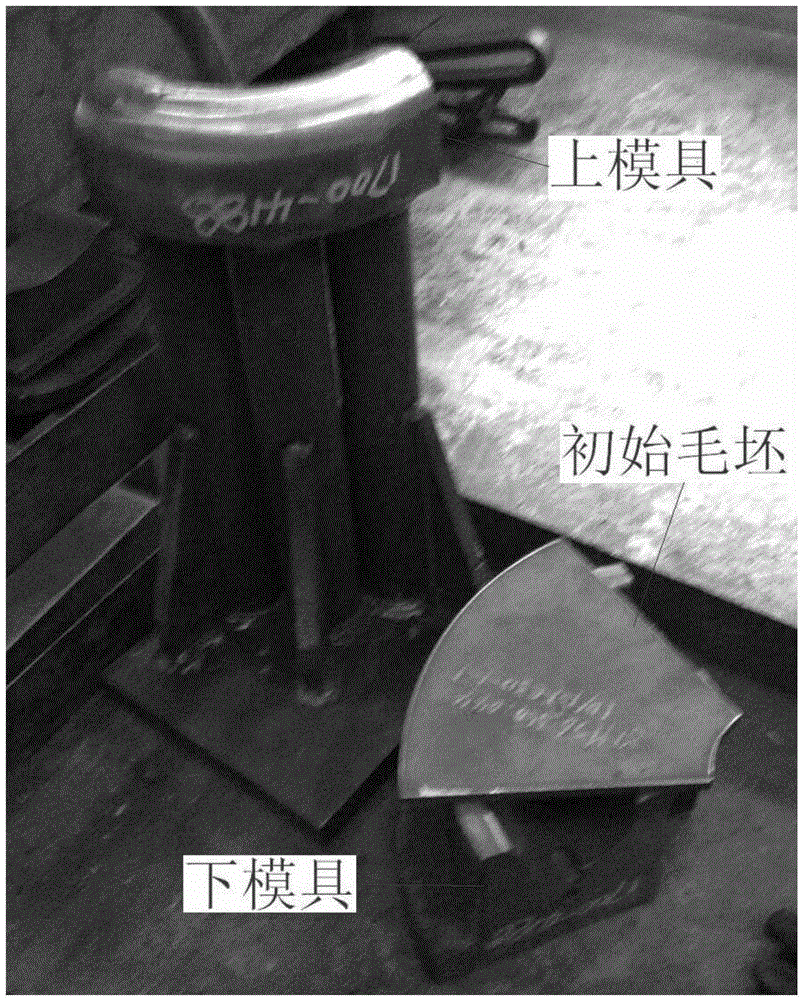

[0041] Specific Embodiment 1: The stamping and welding forming method of a BFe30-1-1 iron-nickel-nickel elbow with a small radius of curvature in this embodiment is specifically prepared according to the following steps:

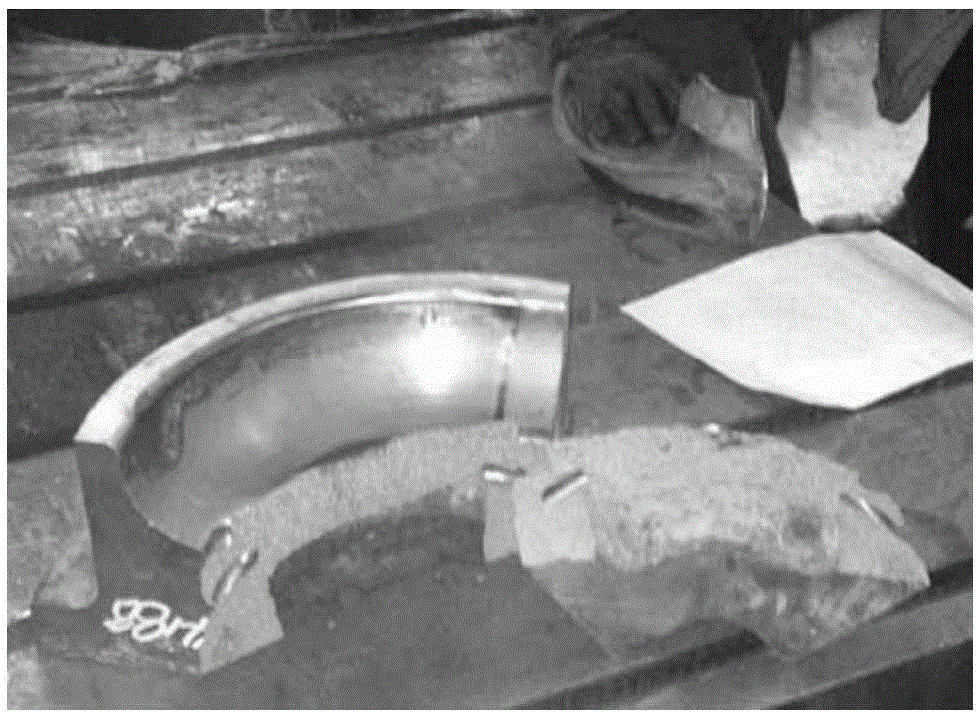

[0042] The plate is cold stamped into two half-rings butt joints. The test is carried out at room temperature, and edge material accumulation occurs, causing the mold to break (such as figure 2 shown);

[0043] During the forming process of the pipe fittings, the inner arc is squeezed and shrinks inward, and the outer arc is stretched and extended outward. figure 2 There are certain problems in the selection of raw materials as shown. Material accumulation occurs at the inner arc where the inner arc is squeezed, which causes the inner arc of the tooling to be subjected to a large extrusion force, causing the mold to break and the parts to be formed are not in place;

[0044] Step 1. Increase the chamfering radius r of the fillet of the lower die of the stam...

specific Embodiment approach 2

[0069] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the radius r of the lower mold is increased to 13 mm or 14 mm. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0070] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, through analysis, it is known that the gap between the mold and the blank is too small, which causes the molding to make the blank go down smoothly, and the mold is redesigned, and the redesigned mold increases In order to improve the hardness, the stamping die is made of No. 45 steel plate, and the hardness is relatively high; among them, the hardness of the original mold is 230-280HBW, and the hardness of No. 45 steel plate is 480-600HBW. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com