A method for decomposing excess sludge and its application in hydrogen production by fermentation

A technology for excess sludge and sludge, which is applied in fermentation, sludge treatment, biological sludge treatment, etc., can solve the problems of difficult sludge reduction and resource utilization, difficult to achieve hydrogen production effect, etc., and achieve high-efficiency production Hydrogen, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: The cracking effect of 10kGy dose irradiation and alkali coupling on excess sludge

[0024] Put 1L of excess sludge in a 1L brown grinding bottle, adjust the pH of the excess sludge to 12 with sodium hydroxide solution, and accept gamma-ray irradiation with a dose of 10kGy at room temperature. The radioactive source is 60 Co. After the irradiation, the pH of the remaining sludge was adjusted to neutral to obtain the decomposed sludge; various indicators in the decomposed sludge mixture were analyzed, and the decomposed effect of the sludge was shown in Table 1.

[0025] Table 1 The cracking effect of sludge under the condition of 10kGy and pH=12

[0026]

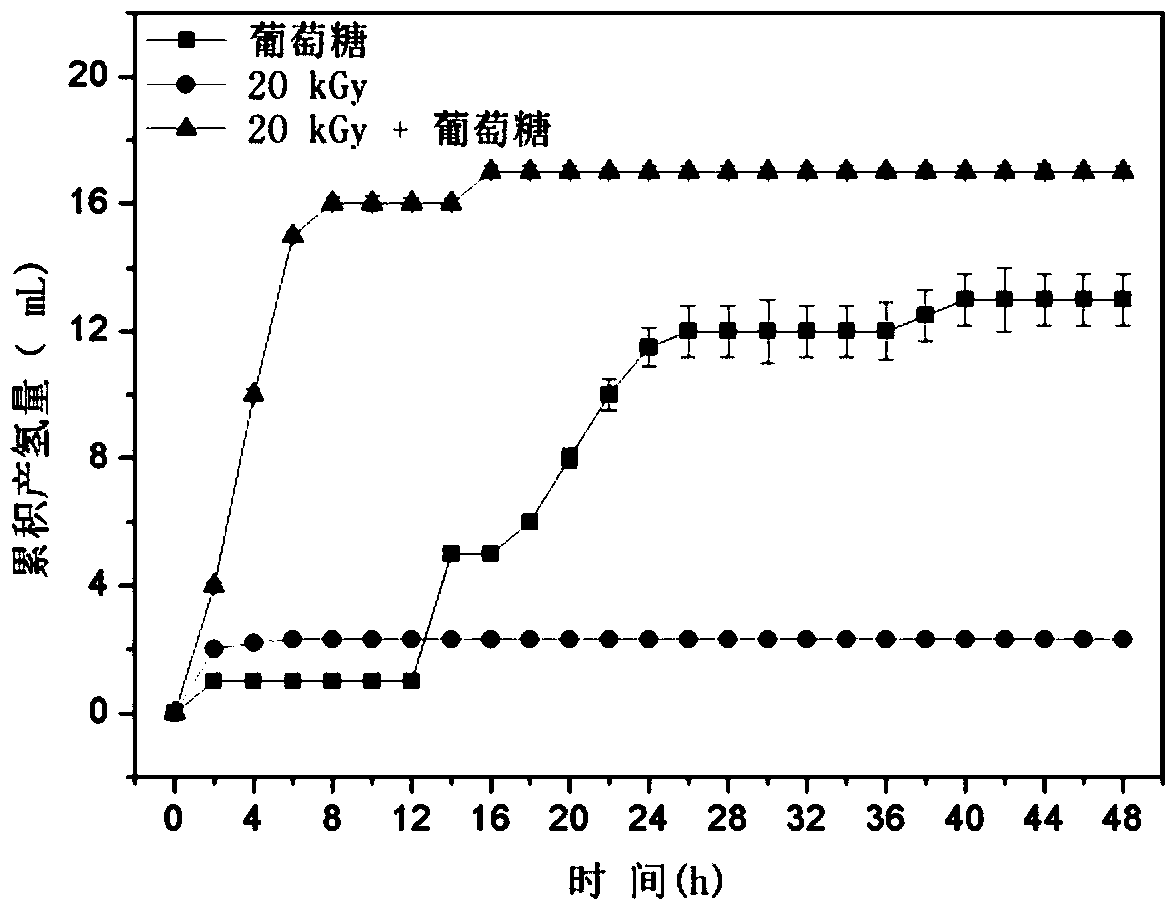

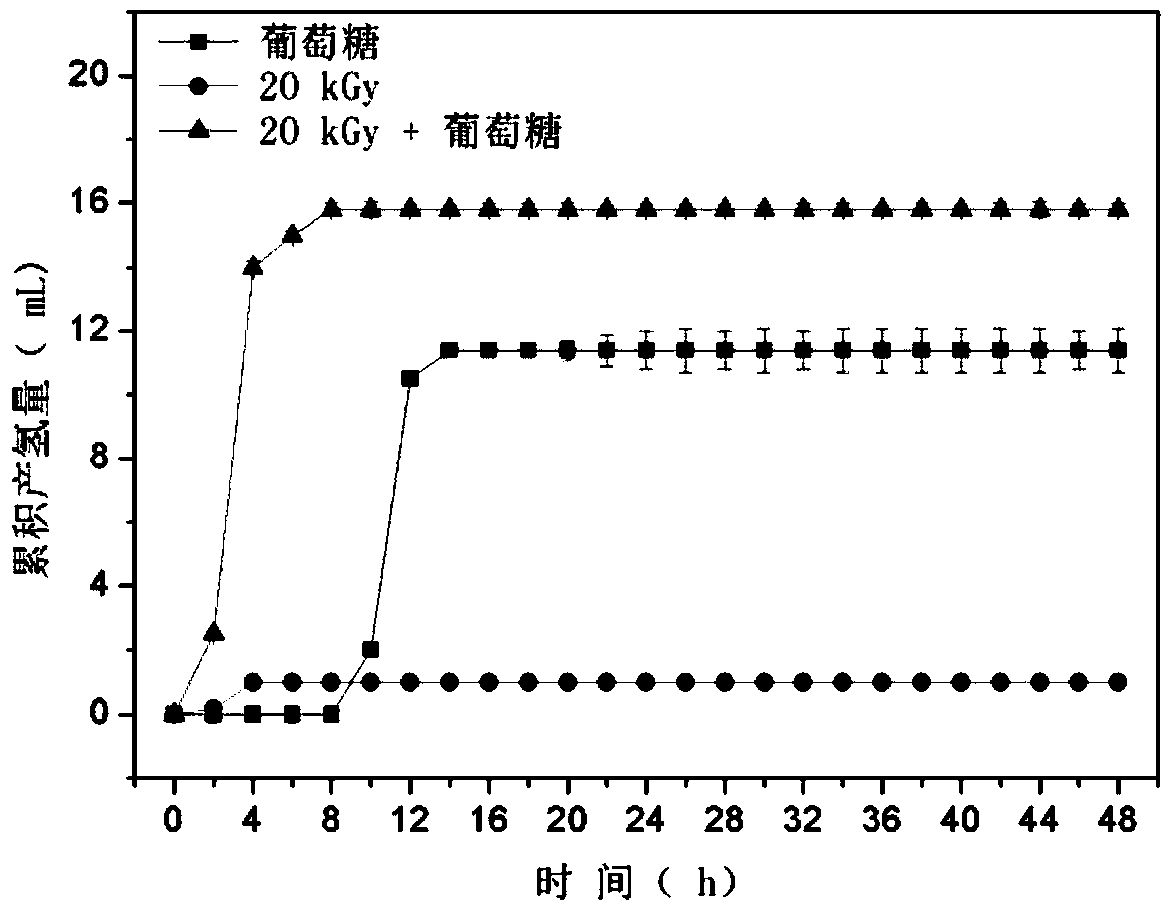

Embodiment 2

[0027] Example 2: The cracking effect of 20kGy dose irradiation and alkali coupling on excess sludge

[0028] Put 1L of excess sludge in a 1L brown grinding bottle, adjust the pH of the excess sludge to 12 with sodium hydroxide solution, and accept gamma-ray irradiation with a dose of 20kGy at room temperature. The radioactive source is 60 Co. After the irradiation, the pH of the remaining sludge was adjusted to neutral to obtain the decomposed sludge; various indicators in the decomposed sludge mixture were analyzed, and the decomposed effect of the sludge was shown in Table 2.

[0029] Table 2 The cracking effect of sludge under the condition of 20kGy and pH=12

[0030]

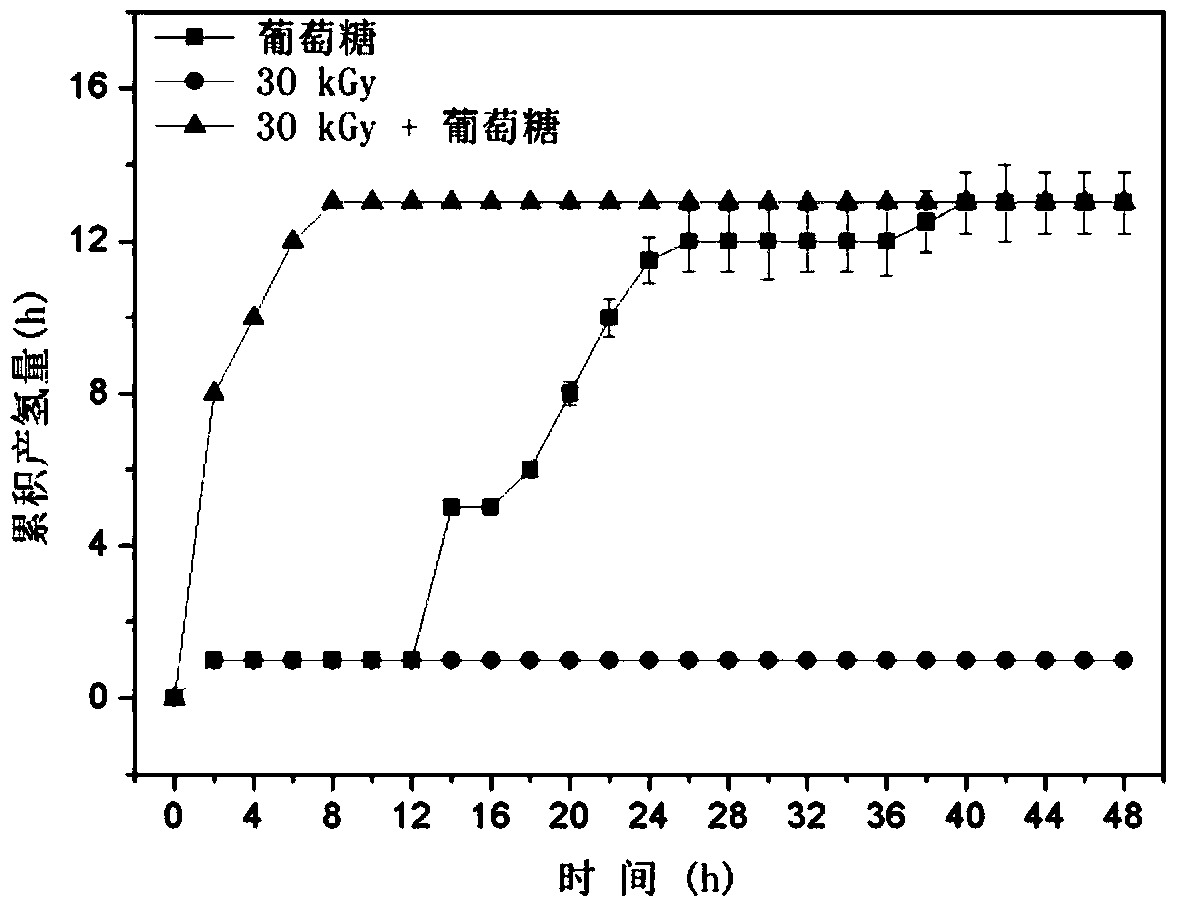

Embodiment 3

[0031] Example 3: The cracking effect of 30kGy dose irradiation and alkali coupling on excess sludge

[0032] Put 1L of excess sludge in a 1L brown grinding bottle, adjust the pH of the excess sludge to 12 with sodium hydroxide solution, and accept a dose of 30kGy of gamma-ray irradiation at room temperature. The radioactive source is 60 Co. After the irradiation, the pH of the remaining sludge was adjusted to neutral to obtain the decomposed sludge; various indicators in the decomposed sludge mixture were analyzed, and the decomposed effect of the sludge was shown in Table 3.

[0033] Table 3 Cracking effect of sludge under the condition of 30kGy, pH=12

[0034]

[0035] Analyzing the results of Examples 1-3, it can be found that under the condition of pH=12, different doses of irradiation have a certain degree of cracking effect on the remaining sludge, and the cracking effect of 10kGy is poor, and the cracking effect of 20kGy is the best. It can be seen that the treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com