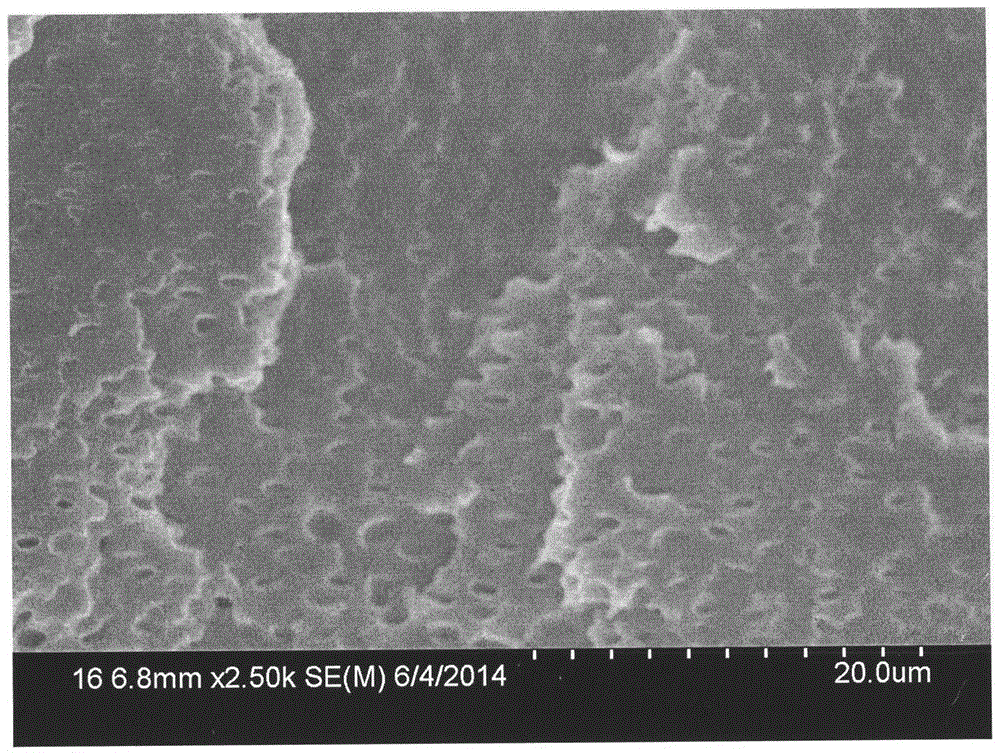

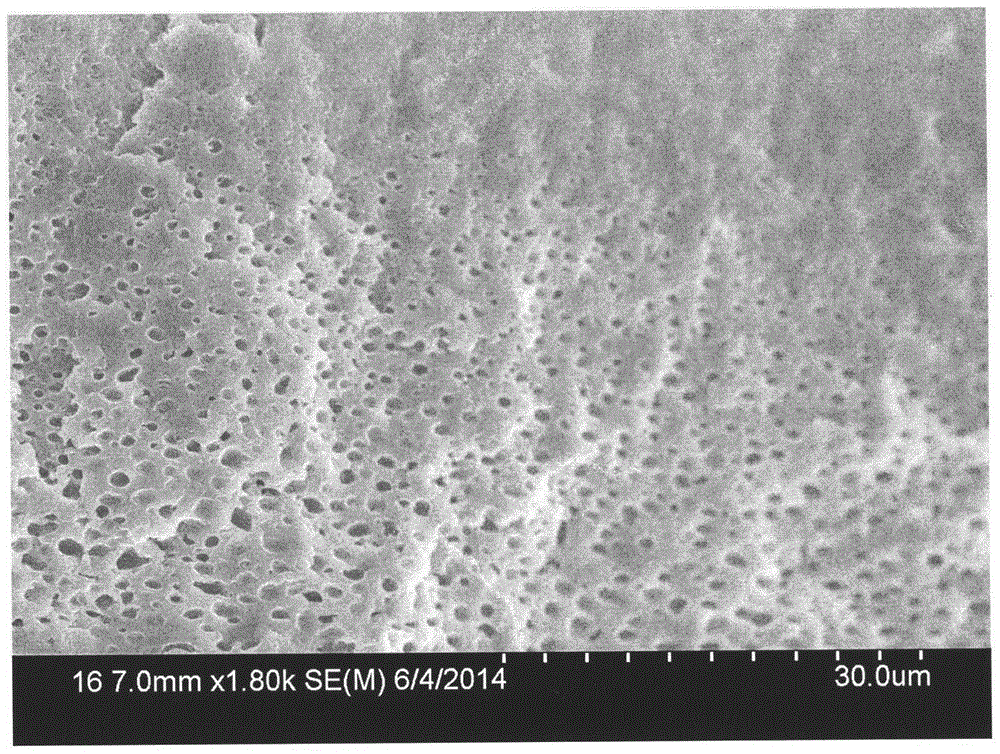

Multi-walled carbon nano-tube/polystyrene composite material film preparation method

A multi-wall carbon nanotube and polystyrene film technology, applied in the field of composite materials, can solve the problems of high specific surface energy, carbon nanotube shedding, poor interfacial bonding force, etc., and achieve improved mechanical properties and thermal stability. , the effect of improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a multi-walled carbon nanotube / polystyrene composite film, the steps of the method are as follows:

[0028] 1) Preliminary mixing of composite solution

[0029] Composite material is by carbon nanotube content 1wt%, 5wt% and three kinds of component contents of 10wt%, gets 0.2g polystyrene, multi-walled carbon nanotube (unmodified multi-walled carbon nanotube, hydroxylated multi-walled carbon nanotubes, hydroxylated carbon nanotubes) 0.002g, 0.01g, 0.02g, 0.1ml of surfactant Triton X-100, put it into a weighing bottle and add 10ml of tetrahydrofuran, and place the configured solution in Stir on a magnetic rotor stirrer at a controlled speed until the polystyrene is completely dissolved, and the components are evenly mixed macroscopically.

[0030] 2) Ultrasonic process of composite material solution

[0031] The preliminarily mixed solution was sonicated in an ultrasonic cleaner for 2.5 hours. The ultrasonic parameters were set to 100w, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com