Air agitation cyanidation leaching gold extraction tank and application

A technology of aeration and stirring and cyanidation leaching, which is applied in the direction of improving process efficiency, can solve the problems of insufficient stirring and other problems, and achieve the effects of fast start-up speed, convenient operation and low requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

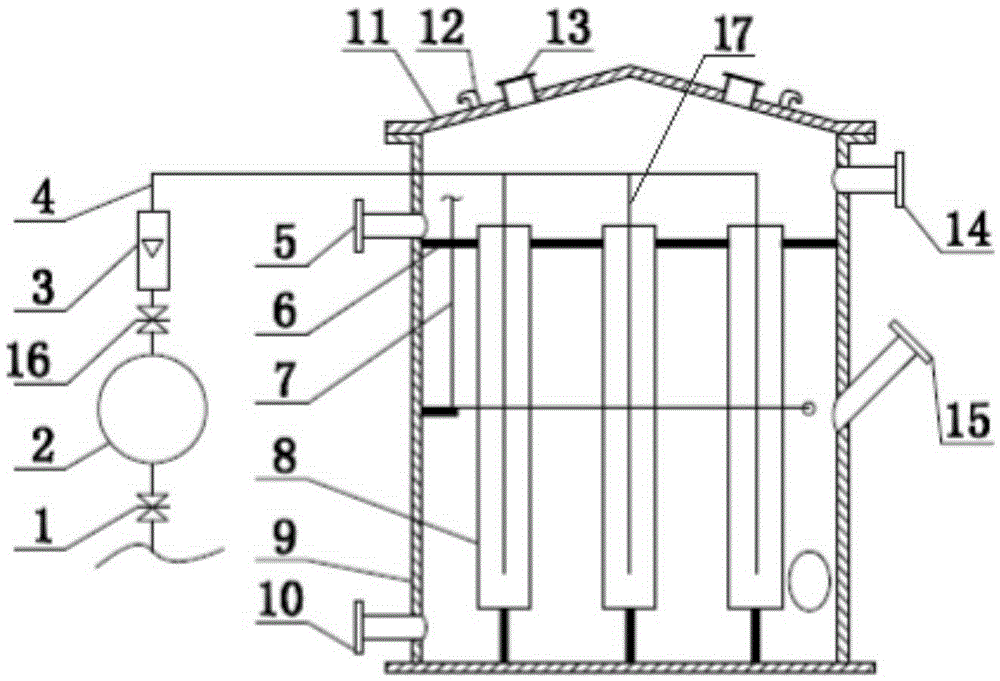

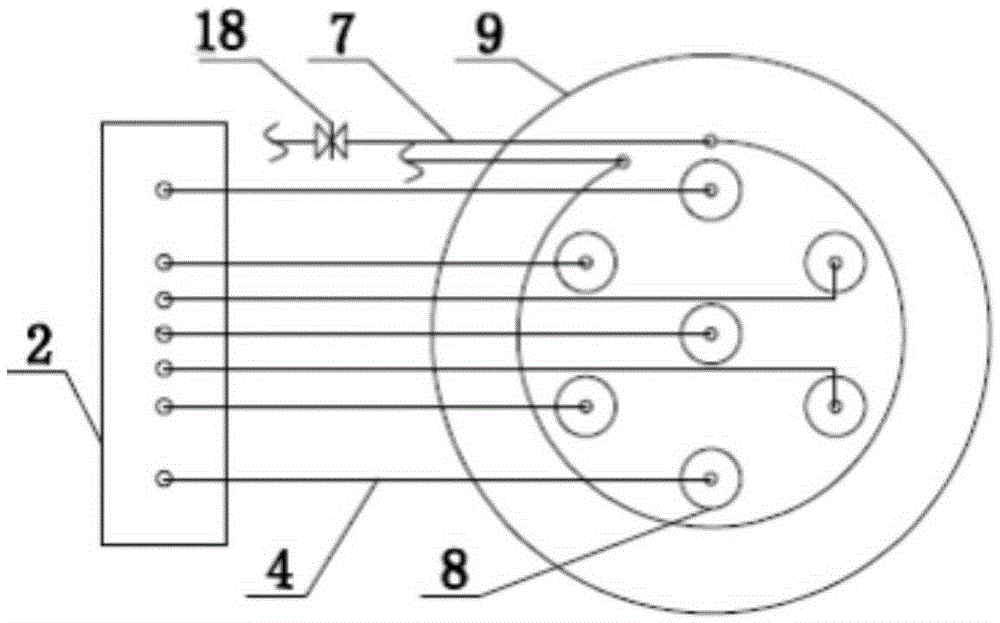

[0031] Such as Figure 1-2 shown.

[0032] An inflatable stirring cyanidation leaching gold extraction tank, comprising a carbon steel tank body 9, a carbon steel tank cover 11, a heating pipe 7 and seven pulp guide tubes 8; the pulp guide tubes 8 are vertically arranged on the carbon steel tank body 9; the slurry guide tube 8 is provided with an inflatable stirring tube 17; the heating tube 7 is arranged around the side wall of the carbon steel tank 9. When the aeration and agitation cyanidation leaching gold extraction tank of the present invention is in use, compressed air is input into the aeration agitation tube 17 through a compressor to perform agitation while aerating. Arranging the inflatable stirring tube 17 in the pulp guide tube 8 avoids the direct contact of the inflatable stirring tube 17 with the pulp, preventing the ore pulp from entering the inflatable stirring tube 17 and causing plugging. Another advantage of this structure is that the pressure air output ...

Embodiment 2

[0034] The gas-inflated stirring cyanidation leaching gold extraction tank as described in Example 1 is different in that the carbon steel tank body 9 is a cylindrical carbon steel tank body with a height-to-diameter ratio of 2; the slurry guide tube 8 is made of carbon steel , the diameter is 500mm; the diameter of the inflatable stirring tube 17 is 30mm; the distance between the slurry guide tube 8 and the bottom of the carbon steel tank 9 is 1000mm. Within this distance range, the mixing effect of the pulp is the best and the dispersion of the pulp is better.

Embodiment 3

[0036] The gas-inflated stirring cyanidation leaching gold extraction tank as described in Example 1 is different in that the heating pipe 7 has a diameter of 50 mm, and a third flow regulating valve 18 is provided at the inlet of the heating pipe 7 . The flow regulating valve is used to control the flow of hot water entering the HVAC pipe 7, and the HVAC pipe 7 heats the ore pulp in cold winter weather to stabilize the reaction temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com