Pipeline plugging construction method based on data simulation

A data simulation and construction method technology, applied in the sewer system, waterway system, water supply device, etc., can solve problems such as subsidence and environmental pollution, achieve the effects of preventing repeated construction, solving pollution, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

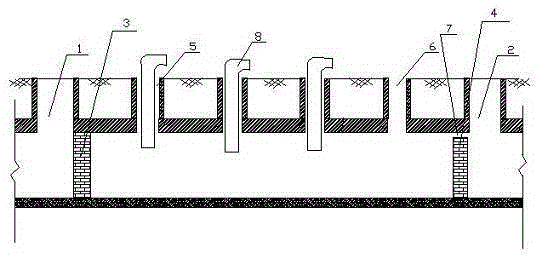

[0025] In the figure, a kind of pipeline plugging construction method based on data simulation of the present invention comprises the following construction steps:

[0026] Step 1. Use the detection instrument before construction, and after calibration before use, press the measuring rod of the detector into the inside of the pipeline, and the detection data will be sent to the detection instrument through the sensor on the measuring tube;

[0027] Step 2, converting the detection data of the detection instrument into a data simulation model, and establishing a mathematical calculation model according to the detection data, the calculation formula of the mathematical calculation model is In the formula, L is the wall thickness of the sealing wall; P is the total water pressure on the water facing surface of the sealing wall; (λ) is the allowable shear stress, which is taken as 0.3-0.8MPa; K is the safety factor, which is generally taken as 1.1-1.3; The calculation results of ...

Embodiment 2

[0035] The difference from embodiment 1 is that if there is a building obstacle in the pipeline separation process in step 4, the length of the pipeline separation will be extended or shortened, not exceeding 20m.

Embodiment 3

[0037] The difference from Example 1 is that the grouting hole 5 and the vent hole 6 in the step 4 are formed by drilling with a drilling machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com