A downhole evaluation device for sacrificial anode materials

A sacrificial anode and evaluation device technology, used in wellbore/well components, measurement, earth-moving drilling, etc., can solve the problems of downhole fluid scouring, peeling, difficult to collect, etc., and achieve low cost, easy installation and disassembly, and easy to fall off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

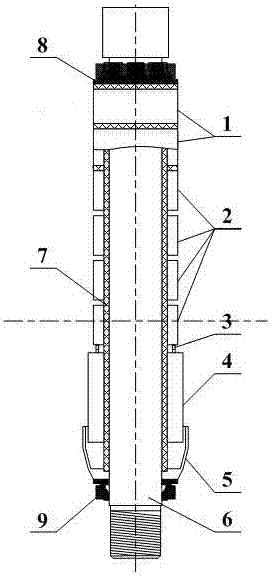

[0023] In order to overcome the problem that the corrosion products of the sacrificial anode are relatively loose, easy to be washed and stripped by downhole fluid, and difficult to collect when evaluating the anticorrosion effect of the sacrificial anode material by the conventional hanging ring device, this embodiment provides a method such as figure 1 The downhole evaluation device for the sacrificial anode material shown includes a non-connecting coupon group 1, a connecting coupon group 2, a sacrificial anode block 4, a product collection tank 5, and a tubing nipple 6. The upper end of the tubing nipple 6 is covered with an upper The locking sleeve 8 has a lower locking sleeve 9 on the lower end, and an insulating inner bushing 7 on the outer side. The outer side of the insulating inner bushing 7 is sequentially covered with a non-connecting hanging piece group 1 and a connecting hanging piece group 2 from top to bottom. , sacrificial anode block 4, the upper and lower end...

Embodiment 2

[0028] On the basis of embodiment 1, this embodiment provides a kind of figure 1 In the downhole evaluation device for the sacrificial anode material shown, in order to facilitate installation and disassembly, the non-connected coupon group 1 is 3 to 6 annular coupons with a thickness of 3mm to 5mm and a height of 50mm to 100mm, and each coupon is provided with There are insulating gaskets, and the connecting hanging piece group 2 is 3 to 6 annular hanging pieces of 3 mm to 5 mm in height and 50 mm to 100 mm in height.

[0029] The materials of the non-connecting coupon group 1, connecting coupon group 2, and connecting screw 3 used in the present invention are consistent with the materials of the protected oil casing and sucker rod, which are N80, J55, P110, 20 # steel or 45 # steel. The number of hanging pieces is selected according to the needs of the site, generally 3 to 6 pieces, all of which are ring hanging pieces of 3mm to 5mm and height 50mm to 100mm. The electrica...

Embodiment 3

[0031] On the basis of embodiment 2, this embodiment provides a kind of figure 1 In the downhole evaluation device for sacrificial anode materials shown, the product collection tank 5 is an upwardly open annular groove made of polyvinyl chloride or nylon, and the insulating inner bush 7 is made of polyvinyl chloride or nylon.

[0032] The product collection tank 5 is an upwardly open annular groove, the size of which is determined according to the actual wellbore space, which is convenient for collecting the corrosion products peeled off from the surface of the anode block, and prevents falling objects from affecting production. Vinyl chloride or nylon are both oil-resistant and anti-corrosion insulating materials.

[0033] Further, the sacrificial anode block 4 contains the following elements: by mass percentage, 5% to 10% zinc, 0.2% to 1.5% indium, 0.2% to 2% magnesium, 0.03% to 0.5% tin, 0.05% to 0.1% % rare earth elements, and the balance is aluminum. The sacrificial anod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com