Dry-wet unified cooling tower adopting natural ventilation and composite running mode and application of dry-wet unified cooling tower

A combined operation mode and natural ventilation technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problem of increased back pressure of steam turbines, reduced unit economy, large amounts of finely treated water, etc. problem, to achieve the effect of increasing heat release, saving water replenishment, and reducing water evaporation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

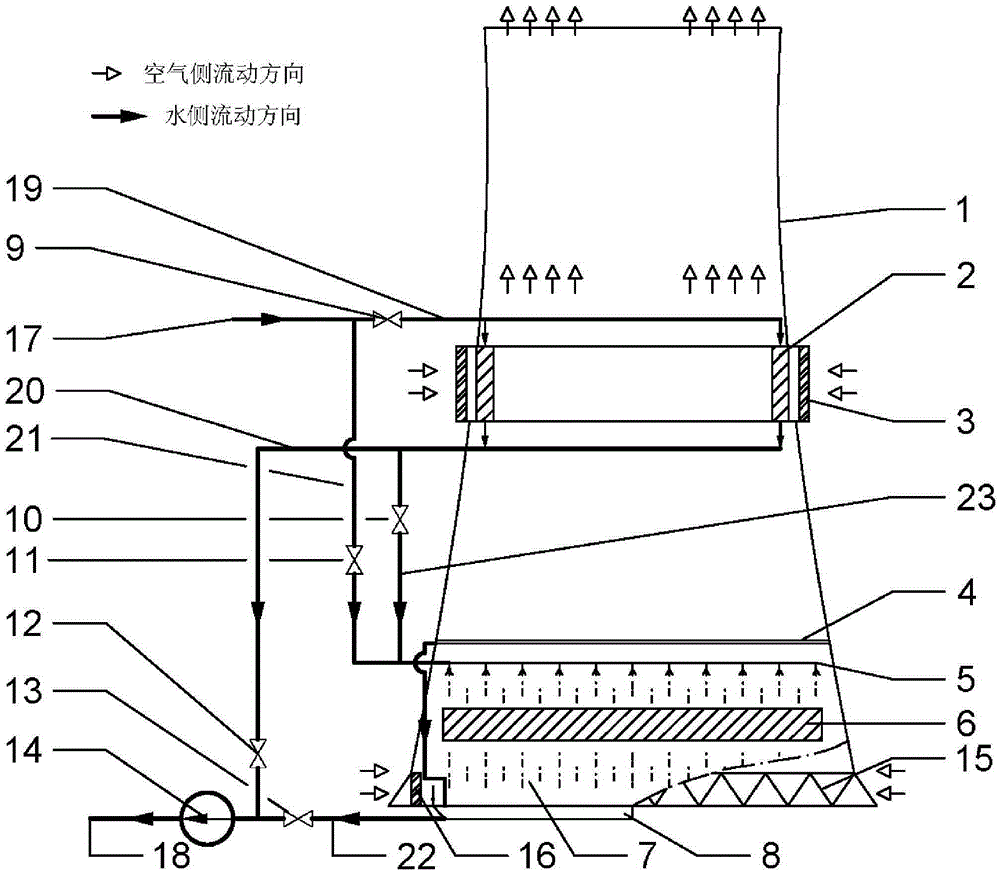

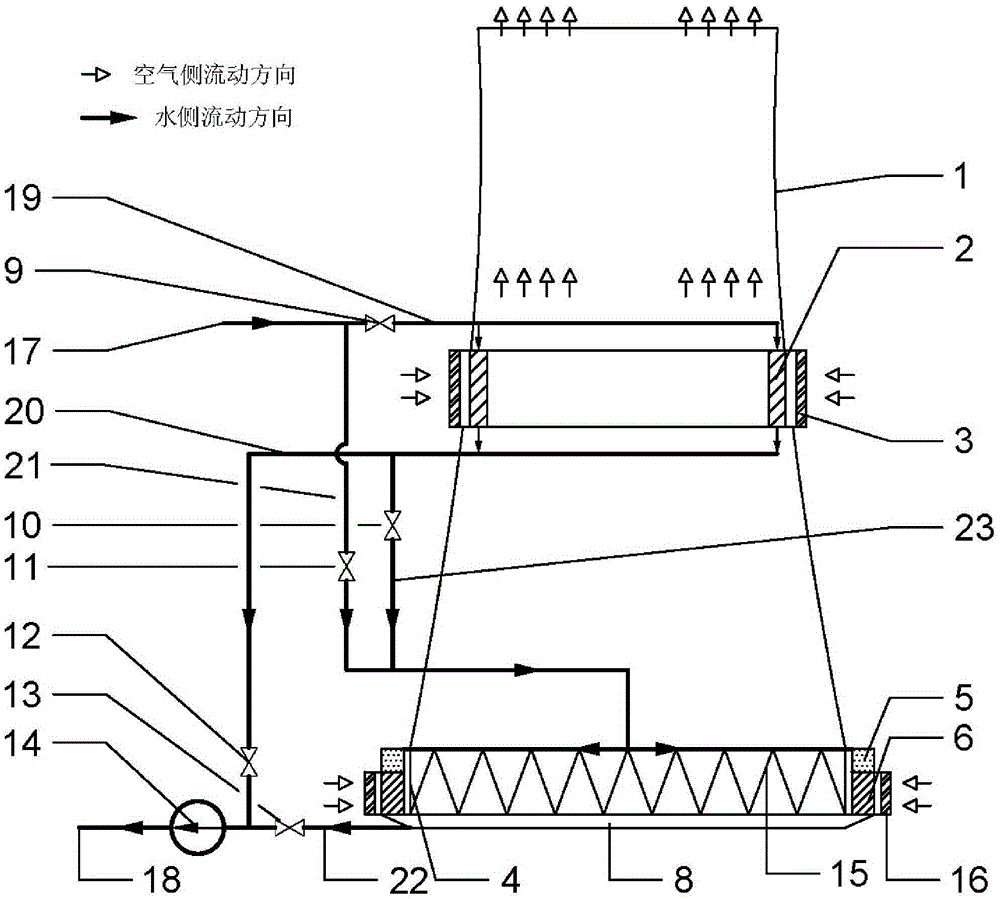

[0044] Example 1: Full Series Operation

[0045] When the ambient meteorological conditions are high temperature and high humidity, the heat transfer conditions are poor. To make full use of the cooling capacity of the dry cooling section and the wet cooling section, the dry cooling section and the wet cooling section can be operated in series to make the tower water temperature meet the requirements. see figure 1 and figure 2 , in the flow distribution system, valves A, B and E are fully open, valves C and D are fully closed, and shutters 3 in the dry-cooling section and shutters 16 in the wet-cooling section are open.

[0046] The circulating cooling water used to cool the condensed steam of the steam turbine first passes through the cooling triangular finned tube bundle of the dry cooling section to exchange heat with the air, and then all reaches the water distribution system 5 of the wet cooling section, and then passes through the lower packing area 6 and the rain area...

Embodiment 2

[0047] Example 2: Full Parallel Operation

[0048] When the ambient meteorological conditions are relatively high and there are more water resources available, the parallel operation mode of the dry cooling section and the wet cooling section can be adopted to make the tower water temperature meet the requirements. see figure 1 and figure 2 , in the flow distribution system, valve A, valve C, valve D and valve E are open, valve B is completely closed, and the shutters 3 in the dry-cooling section and the shutters 16 in the wet-cooling section are open.

[0049] The cooling water from the steam turbine condenser passes through the dry cooling section and the wet cooling section independently, and the flow ratio of the two parts can be adjusted by the opening of the valve. In the dry cooling section, the cooling water exchanges heat with the air in the cooling triangular finned tube bundle 2; in the wet cooling section, the cooling water enters the water distribution system 5...

Embodiment 3

[0050] Example 3: first in series and then in parallel

[0051] When the ambient temperature is relatively high but the water resources are scarce, the operation mode in which all the flow passes through the dry cooling section and part of the flow passes through the wet cooling section can be adopted. see figure 1 and figure 2 , in the flow distribution system, valve A and valve E are fully open, valve C is fully closed, valve B and valve D are in a certain opening state, and the louvers 3 of the dry-cooling section and the louvers 16 of the wet-cooling section are open.

[0052] The entire flow of cooling water from the steam turbine condenser passes through the dry cooling section 2 to exchange heat with the air in the cooling tower, and then part of the flow continues to exchange heat with the air through the wet cooling section, and then this part of the flow is compared with the flow that does not flow through the wet cooling section Export after mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com