Control system for I-type and T-type three-level bidirectional PWM (Pulse-Width Modulation) rectifiers

A control system, three-level technology, applied in electrical components, conversion devices for converting AC power input to DC power output, and output power, etc., can solve the problems of slow operation speed and untimely dynamic response, and reduce the budget burden. , Improve real-time performance and stability, and improve the effect of EMI characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

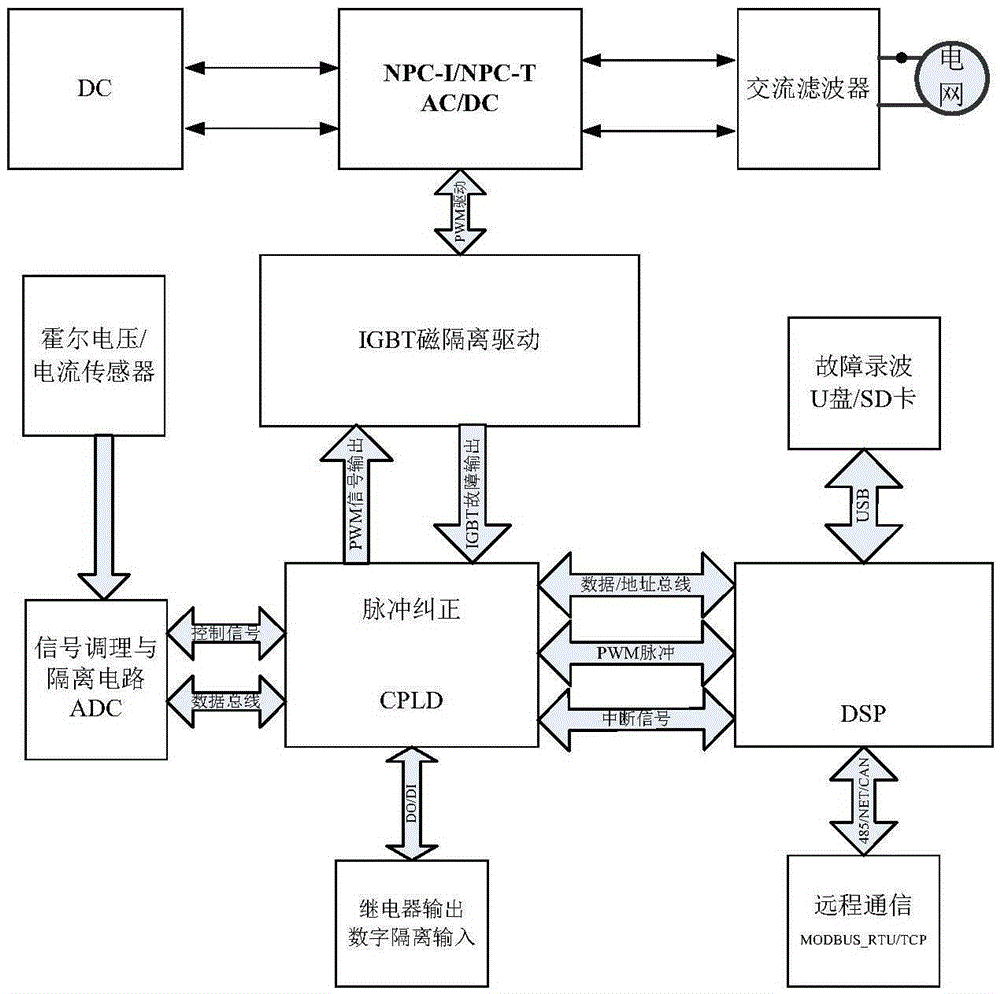

[0018] Through the following examples, combined with the attached figure 1 , the technical solution of the present invention will be further specifically described.

[0019] An I-type and T-type three-level bidirectional PWM rectifier control system, including analog data acquisition and conditioning circuit, IGBT magnetic isolation drive circuit, control circuit composed of DSP and CPLD, relay output and digital signal input, fault recording and Remote communication, characterized in that Hall sensor data acquisition circuit, IGBT drive circuit, input and output interface circuit are connected with CPLD chip, communication circuit and fault recording circuit are connected with DSP, and DSP and CPLD are output through data, address bus and PWM The signal is connected to the interrupt signal.

[0020] The analog quantity acquisition circuit consists of a Hall current sensor output conditioning circuit, a differential voltage acquisition and conditioning circuit and an analog-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com