Impact-free rectangular plate piezoelectric micro-motor

A plate piezoelectric and micro-motor technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. Shock and other problems, to achieve the effect of solving the problem of driving stability, large output torque and eliminating shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

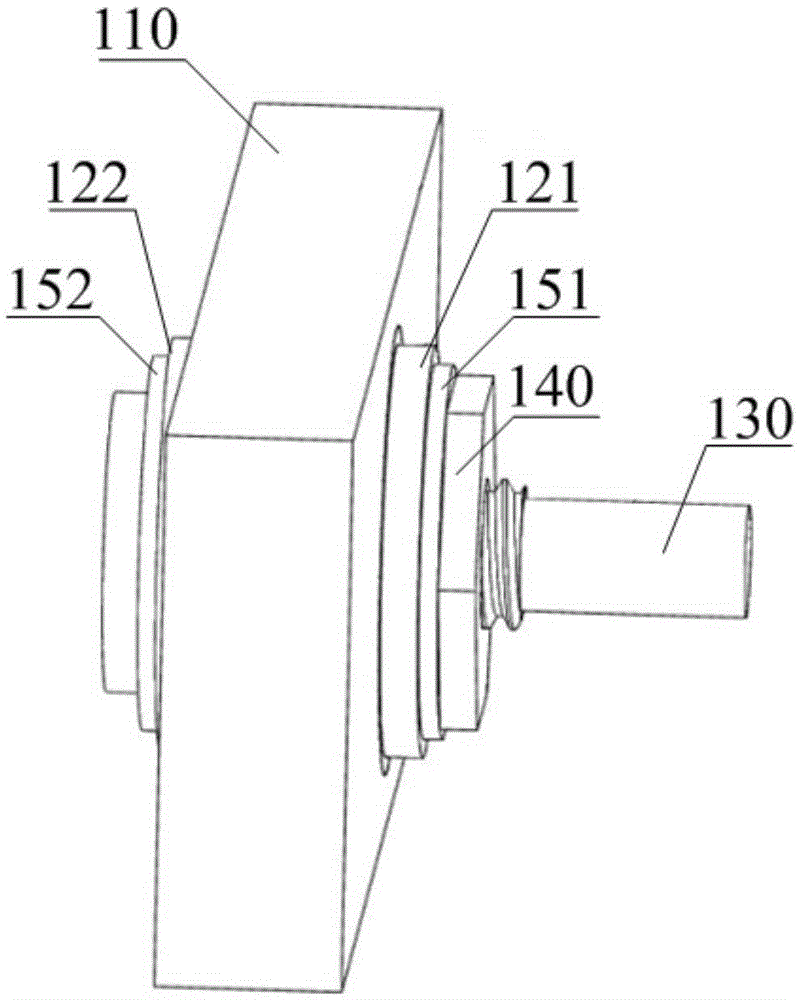

[0041] In a preferred embodiment of the present invention, a piezoelectric micromotor with a rectangular plate without impact is provided, such as figure 1 and 7 As shown, it includes a stator 110 , a first rotor 121 , a second rotor 122 , an output shaft 130 , a fastener 140 , a first pre-tension mechanism 151 and a second pre-tension mechanism 152 .

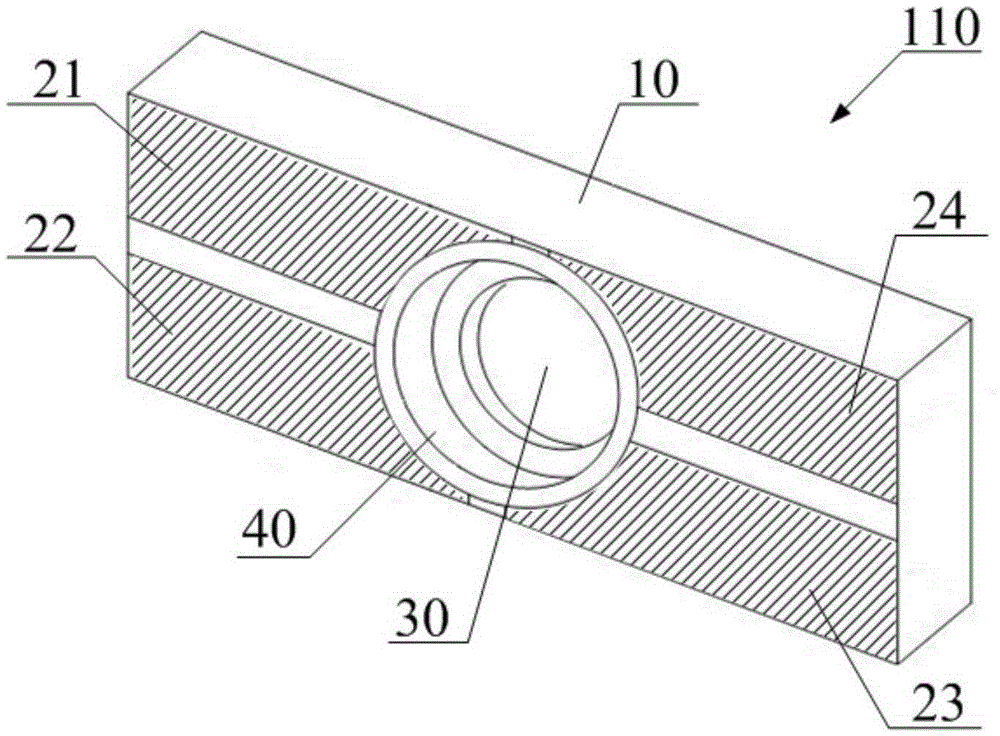

[0042] The stator 110 includes a substrate with a through hole, and the surface of the through hole serves as the driving surface of the micromotor. In this embodiment, the substrate is a rectangular metal plate 10, such as figure 2 shown. It has two surfaces (due to the width of the four surfaces extending in its thickness direction, that is, the thickness of the metal plate 10, is small, the four surfaces are not considered here), one is figure 2 The first surface visible in the paper facing the paper, the other is figure 2 The invisible second surface facing away from the paper. The center of the metal plate 10 has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com