Two-stage fine filter device and two-stage fine filter method for fracturing flow-back fluid

A fracturing flowback fluid and fine filtration technology, which is applied in the direction of filtration circuit, filtration separation, separation device, etc., can solve the problems of high cost, complex process, difficult treatment, etc., and achieve convenient maintenance, short process flow and stable operation sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

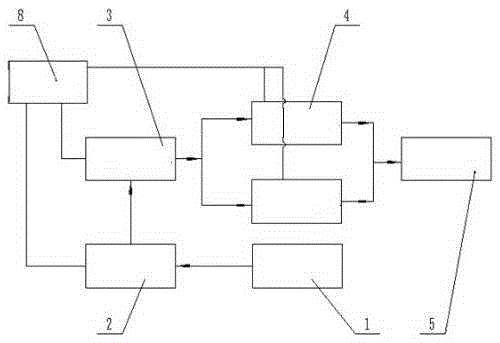

[0030] In order to overcome the existing problems of difficult treatment of fracturing flowback fluid, complicated process and high cost, the present invention provides such as figure 1 , figure 2 , image 3 , Figure 4 The device and method for the fine filtration of oil and gas well fracturing flowback fluid are shown. For the recyclable fracturing fluid, after fine filtration, the content of suspended solids can be effectively reduced, and the water quality requirements for repeated configuration of fracturing fluid can be met; Fracturing fluid that cannot be recycled can be processed after fine filtration to remove suspended impurities.

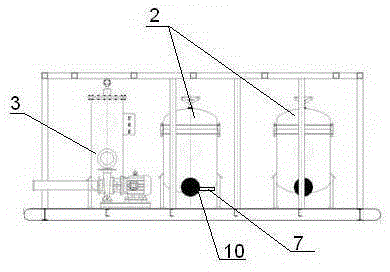

[0031] A fine filtration device for fracturing flowback fluid, comprising a liquid storage tank 1, a lift pump 2, a primary filter 3, two secondary filters 4 arranged in parallel, and a storage tank 5, the liquid storage tank 1 and the lift pump 2 The water suction pipe of the lift pump 2 is connected to the water inlet pipe at the up...

Embodiment 2

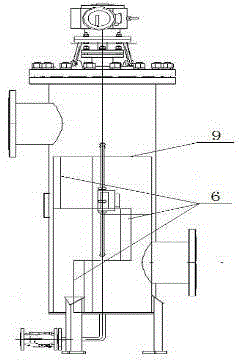

[0035] On the basis of Embodiment 1, in the present embodiment, the primary filter 3 is provided with a primary filter screen 9, and the primary filter screen 9 adopts a metal cylindrical filter screen with a filtration accuracy of 50- 100 μm.

[0036] The primary filter 3 is a motor steel brush filter, and a stainless steel brush 6 is arranged in the filter screen 9 of the primary filter.

[0037] The secondary filter 4 is provided with a secondary filter screen 10 with a filtration accuracy of 0.5-20 μm.

[0038] The secondary filter 4 is a multi-bag filter, and filter bags 7 are arranged in the filter screen 10 of the secondary filter.

[0039] The filter bag 7 is a filter bag of polypropylene, polyester or PTFE polytetrafluoroethylene.

[0040] Both the primary filter 3 and the secondary filter 4 are installed vertically.

[0041] The first-stage filter is installed vertically, the water inlet pipe of the first-stage filter is located at the upper part, and the water ou...

Embodiment 3

[0047]Based on the above embodiments, in this embodiment, a method for finely filtering fracturing flowback fluid includes the following steps:

[0048] Step 1: After desanding, the fracturing flowback fluid enters the liquid storage tank 1, and the fracturing flowback fluid stored in the liquid storage tank 1 enters the primary filter 3 under the action of the lift pump 2;

[0049] Step 2: Preliminarily filter the fracturing flowback fluid through the primary filter 3 to filter out large particles in the water, and then enter the secondary filter 4 from the primary filter 3;

[0050] Step 3: Filter the fracturing flowback fluid again through the secondary filter 4 to remove suspended matter and colloids in the water, and then enter the storage tank 5 .

[0051] The large particulate matter in the step 2 refers to particles with a particle size greater than 50 μm; the suspended solids and colloids in the step 3 have a particle size greater than 0.5 μm.

[0052] The steps 2 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com