ZnO@ZIF-8 core-shell structure compound as well as preparation method and application thereof

A core-shell structure and composite technology, which is applied in chemical instruments and methods, water treatment of special compounds, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of less research on core-shell structure, and achieve the goal of preparing The method is simple and the effect of great application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1Z

[0024] The synthesis of embodiment 1ZnO hollow sphere

[0025] Add 0.5g of zinc acetate and 43mg of silicotungstic acid into a reaction kettle filled with 10ml of water, and stir for 0.5-1h at room temperature; -1 The heating rate of the reaction kettle was raised to 120 degrees Celsius and reacted for 72 hours to obtain a white precipitate, which was filtered, washed and dried to obtain ZnO hollow spheres. The yield was 85%.

Embodiment 2Zn

[0026] The synthesis of embodiment 2ZnOZIF-8 core-shell structure composite material

[0027] ZnO21mg, 2-methylimidazole 170mg are added in the mixed solution of DMF and water 3:1, after ultrasonic 10min, the stainless steel autoclave of polytetrafluoroethylene lining that mixed solution is housed is put into baking oven, with 15 -20℃·h -1 The heating rate of the oven was raised to 75 degrees Celsius, and the reaction was carried out for 24 hours to obtain a white precipitate, which was filtered, washed, and dried to obtain a ZnOZIF-8 core-shell structure complex. The yield was 78%.

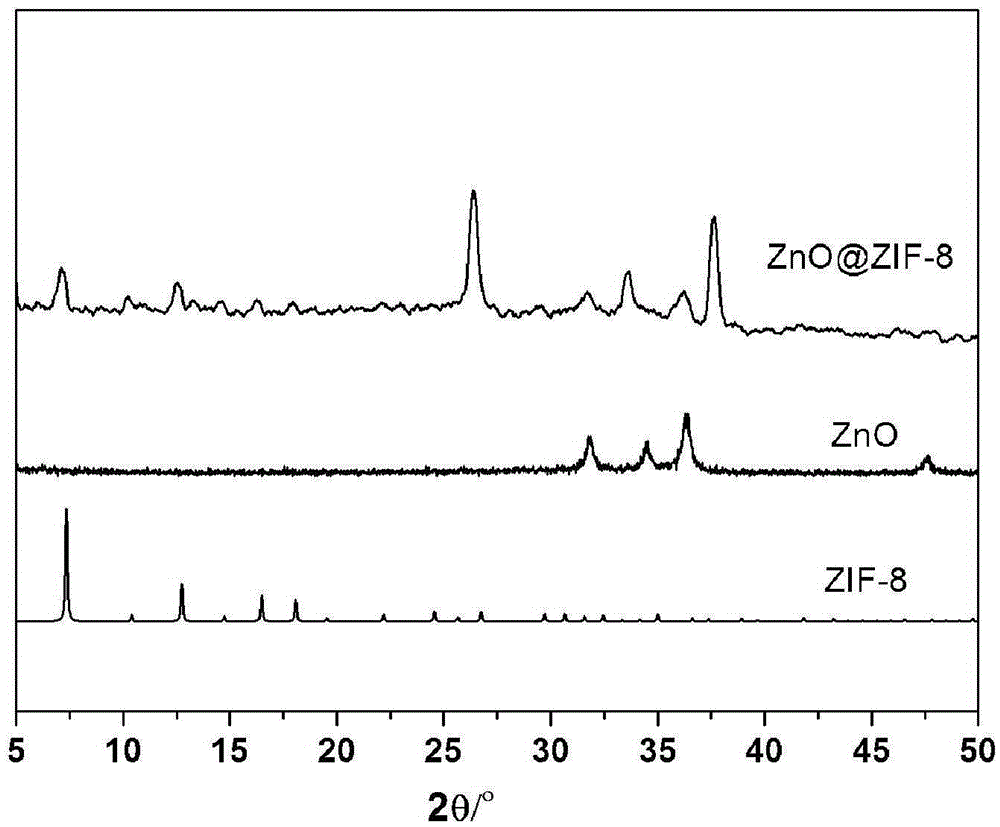

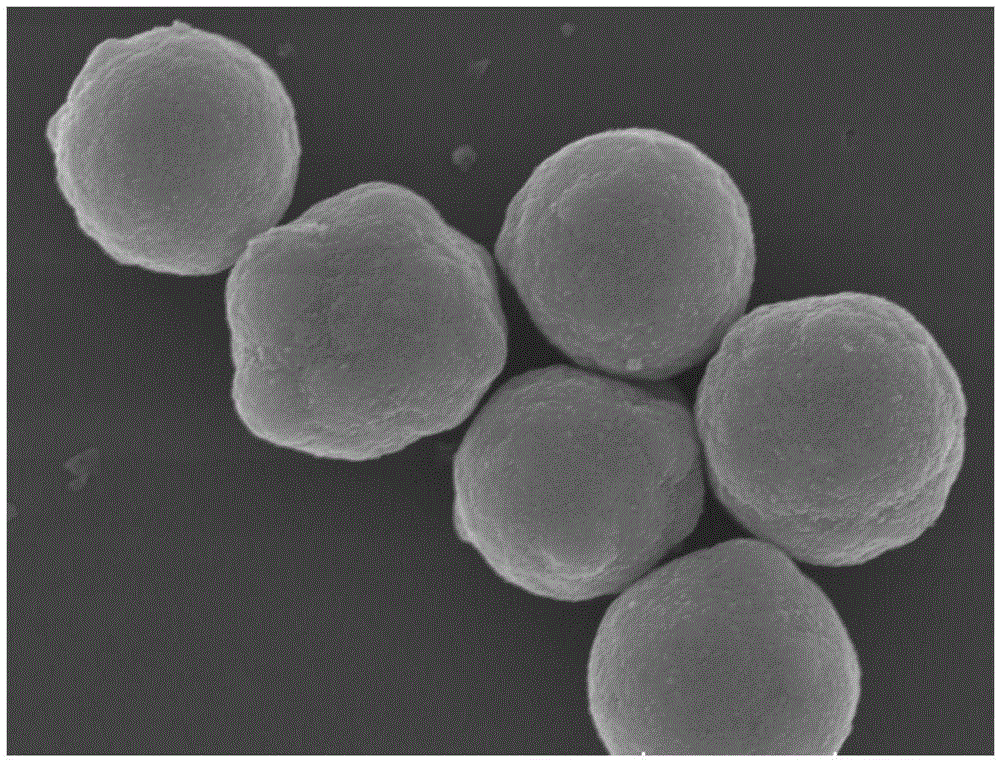

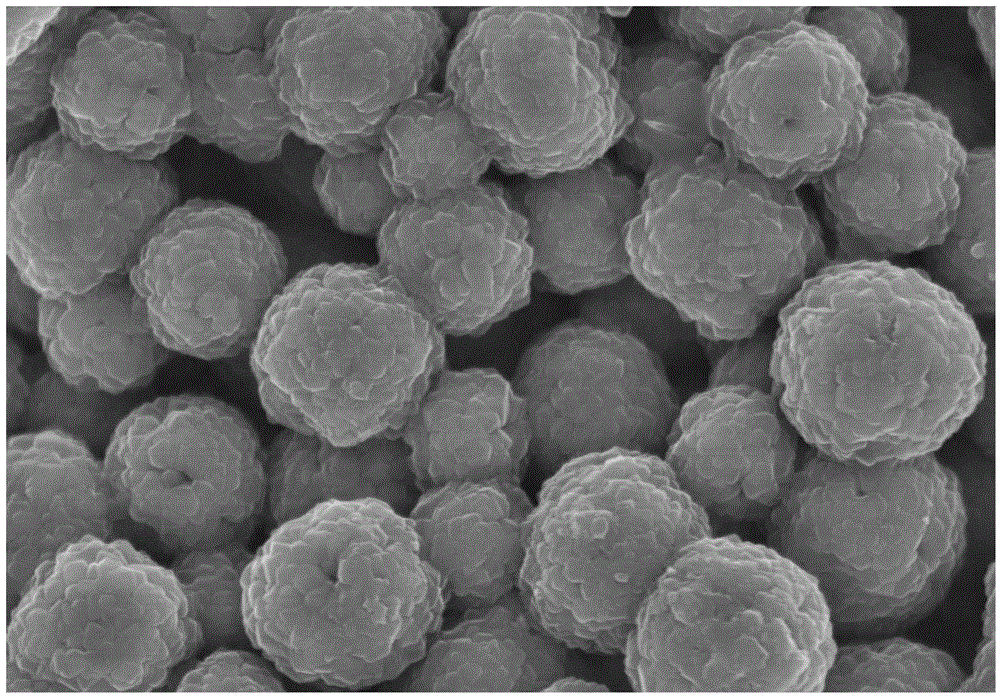

[0028] The present invention synthesizes the XRD of ZnOZIF-8 core-shell structure complex as figure 1 As shown, the characteristic peaks of ZnO and ZIF-8 are consistent with the complex ZnOZIF-8, indicating that the synthesized material contains both ZnO and ZIF-8. The ZnO hollow sphere synthesized by the present invention is as figure 2 As shown, the diameter of ZnO is 1 micron. ZnOZIF-8 c...

Embodiment 3Zn

[0029] Example 3 ZnOZIF-8 core-shell structure composite photocatalytic degradation of organic dyes

[0030] (1) Effect of initial concentration of organic dyes on degradation rate

[0031] Get respectively the rhodamine B dye solution 100ml that concentration is 10mg / L, add 10mg catalyst ZnOZIF-8 (embodiment 1 and 2 preparation), stir, dark reaction 30 minutes, utilize xenon lamp to irradiate rhodamine B dye solution, every 10 minutes with Changes in the concentration of the dye in the dye solution are detected by UV-Vis spectroscopy. The result is as Figure 5 As shown, the intensity of the characteristic peak at 552nm decreases gradually, and the dye is degraded after being irradiated with a xenon lamp, and the final degradation rate reaches 47% in 70 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com