Asynchronous stagger spinning machining method

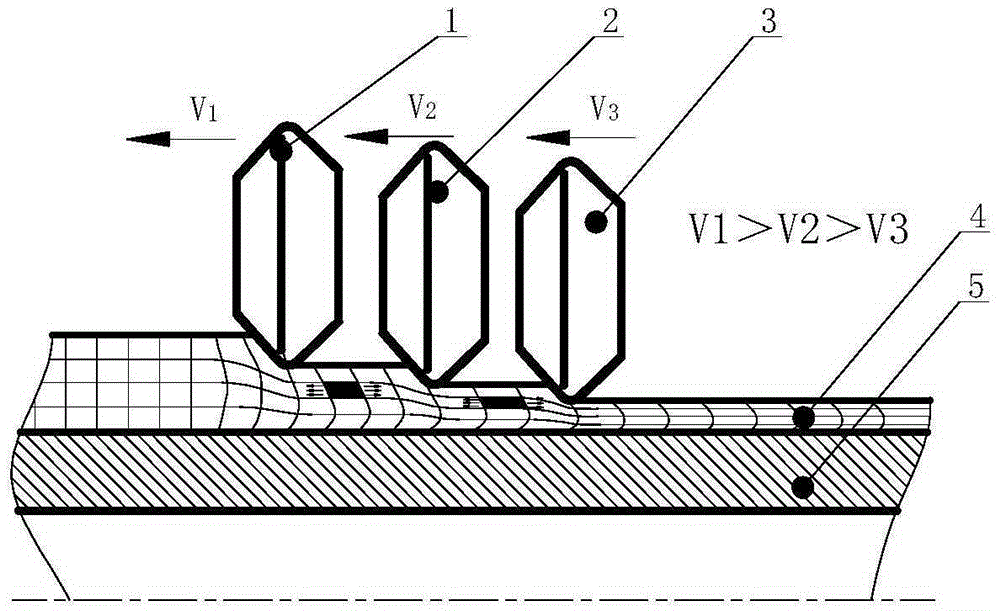

A technology of staggered spinning and processing methods, which is applied in the field of spinning manufacturing, can solve the problems of high scrap rate and poor precision, and achieve the effects of easy flow, reduced spinning pressure, and refined metal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment is a spinning machine in which each rotary wheel can be fed axially independently, and uses a two-rotary wheel asynchronous staggered pitch spinning method to process ultra-high-strength steel thin-walled cylindrical parts. The wall thickness t of the spinning blank of the cylindrical part 0 =8mm, outer diameter D=Φ312mm.

[0034] The concrete process of this embodiment is:

[0035] The first step is to install the spinning blank of the cylindrical part. The cylindrical member spinning blank 4 is installed on the spinning mandrel 5 of the spinning machine.

[0036] The second step is to adjust the angle of attack of the rotary wheel. Described rotary wheel has two, is R8 / 30 ° rotary wheel. Each rotary wheel moves to the spinning end of the cylindrical piece spinning blank, and the angle of attack of the rotary wheel is adjusted to be perpendicular to the axis of the cylindrical piece spinning blank. The axial offset between the rollers is 6-8mm, the...

Embodiment 2

[0047] This embodiment is a spinning machine in which each rotary wheel can be fed axially independently, and a three-roller asynchronous staggered pitch spinning method is used to process ultra-high-strength steel thin-walled cylindrical parts. The wall thickness t of the spinning blank of the cylindrical part 0 =10mm, outer diameter D=Φ312mm.

[0048] The concrete process of this embodiment is:

[0049] The first step is to install the spinning blank of the cylindrical part. The cylindrical member spinning blank 4 is installed on the spinning mandrel 5 of the spinning machine.

[0050] The second step is to adjust the angle of attack of the rotary wheel. Described rotary wheel has three, is R8 / 30 ° rotary wheel. Each rotary wheel moves to the spinning end of the cylindrical piece spinning blank, and the angle of attack of the rotary wheel is adjusted to be perpendicular to the axis of the cylindrical piece spinning blank. The axial offset between the rollers is 6-8mm, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com