Solid-phase diffusion bonding method for integrated expanded jointing and welding of tube sheet structure

A diffusion connection and tube-sheet technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as complex production process, high-temperature joint relaxation, crevice corrosion, etc., achieve simple process, enhanced joint sealing, avoid crack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

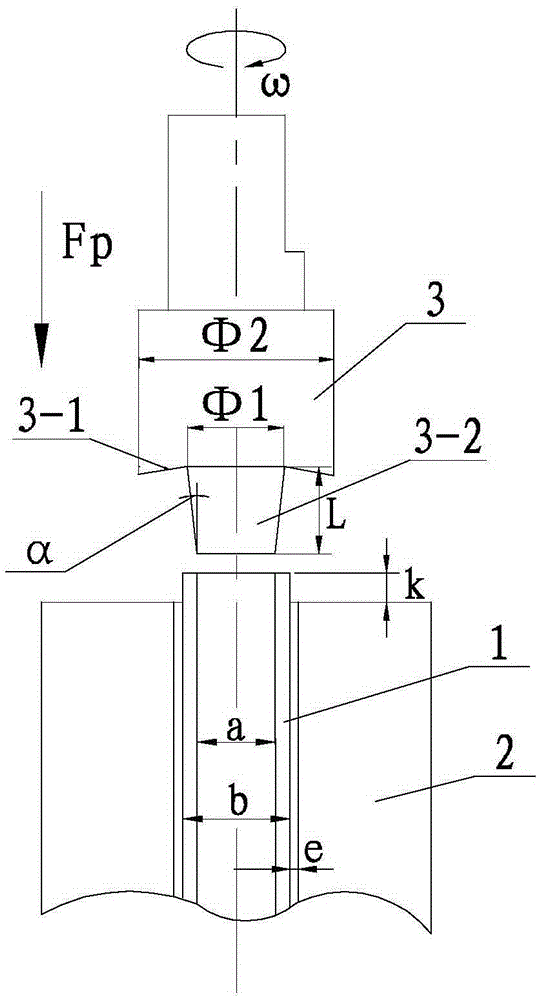

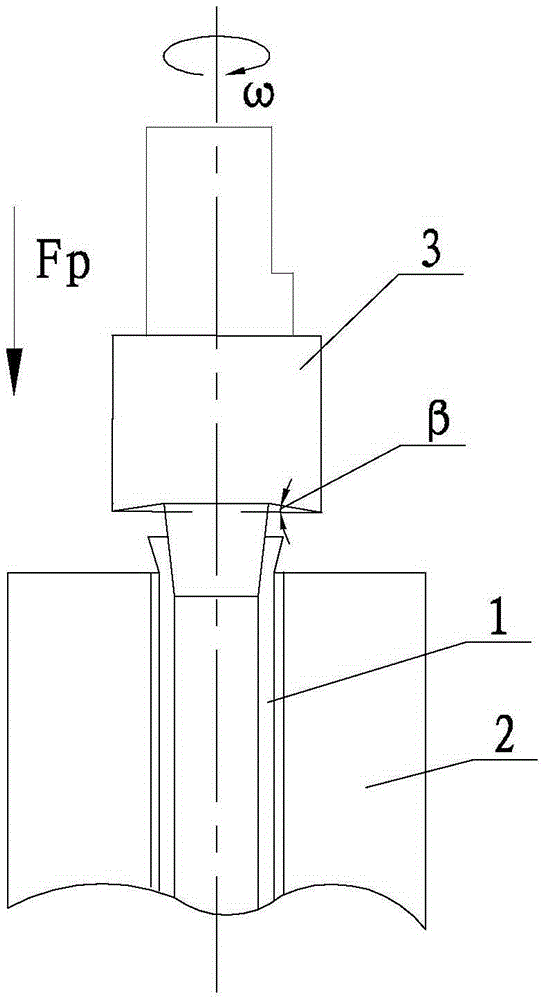

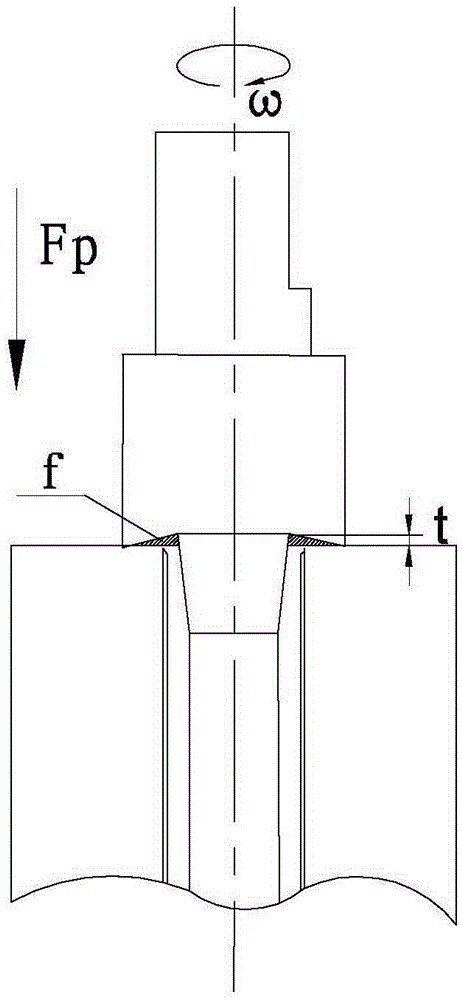

[0021] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this implementation mode, this implementation mode is realized through the following steps:

[0022] Step 1. Cleaning before welding: first remove the oxide film on the surface of the material of the tube 1 and tube sheet 2 to be welded by mechanical grinding, and then use an organic solvent or cleaning agent to wipe the surface of the tube 1 and tube sheet 2 to remove oil and metal dust;

[0023] Step 2, clamping of tube 1 and tube plate 2: when clamping, the gap between the outer wall of tube 1 and the inner hole of tube plate 2 is e, and the length of the upper end of tube 1 protruding from the upper end surface of tube plate 2 is k, see figure 1 ;

[0024] Step 3. Friction welding: the high-speed rotating friction head 3 is inserted into the inner hole of the pipe 1 at a certain pressing speed, so that the pipe 1 is rubbed between the friction head 3 and the pipe 1 to generate heat, and the h...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination figure 1 To illustrate this embodiment, in this embodiment, the organic solvent in step 1 is alcohol or acetone. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination figure 1 Describe this embodiment. In this embodiment, in step 2, the gap e between the outer wall of the tube 1 and the inner hole of the tube sheet 2 is 0.05 mm to 0.25 mm. Select the value of the gap e according to the selected material and performance. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com