Quick changeover method for products of multi-station processing center

A machining center, multi-acupoint technology, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problem of long measurement time and processing time, and achieve the effect of reducing the debugging rejection rate, reducing the measurement time, and obvious advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

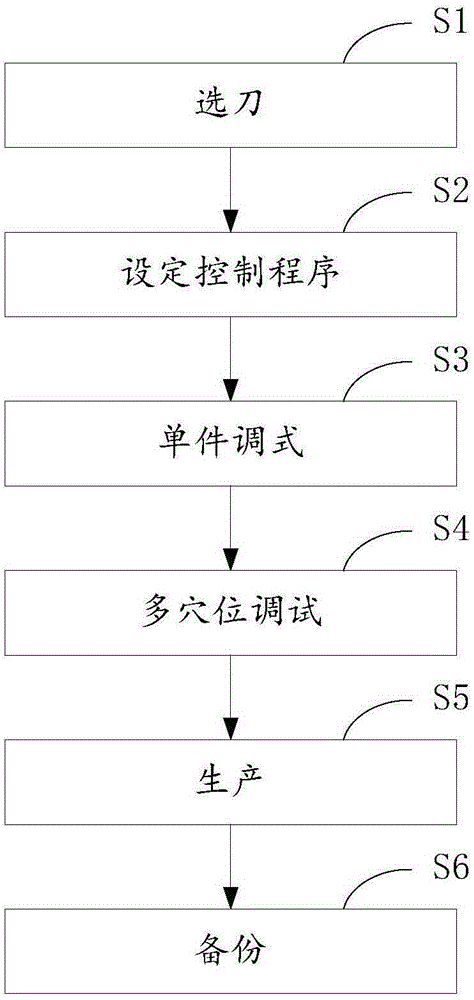

[0031] see figure 1 , the present invention discloses a method for quick product line change in a multi-acupoint machining center, the method comprising:

[0032] 【Step S1】Choose a tool; choose a tool with a diameter of 6-8mm, with a drill point and a step at the same time; install the tool on the machine tool after the length of the tool is adjusted; too small a diameter is not conducive to cutting, and the blank is easy to be scrapped after debugging if it is too large. There is a drill tip for easy centering, reliable position accuracy, and a step for measuring the Z-direction depth;

[0033] [Step S2] Set the control program; set a simple processing program and corresponding measurement program for each series of products, and process one hole on each surface of the product in the processing program; the hole position should be selected on the larger hole of the finished product , and the position coordinates should be consistent with the finished product coordinates, and...

Embodiment 2

[0039] see figure 1 , the present invention discloses a method for quick product line change in a multi-acupoint machining center, the method comprising:

[0040] Step 1. Choose a knife.

[0041] Choose a tool with a diameter of about 6-8mm and a drill point and a step. After the tool length is aligned, it can be installed on the machine tool. (If the diameter is too small, it is not conducive to cutting. If the diameter is too large, the blank will be easily scrapped after debugging. When there is a drill point, the centering is better, so the position accuracy is reliable. With a step, it is convenient to measure the Z-direction depth.)

[0042] Step 2. Programming.

[0043] Each series of products can write a simple processing program and corresponding measurement program. In the processing program, one hole can be processed on each surface of the product (the hole position should be selected on the larger hole of the finished product, and the position coordinates should...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com