Mesoporous nanometer FeCoOx complex preparation method

A composite and nanotechnology, applied in the direction of nanotechnology, cobalt compound, nanotechnology, etc., can solve the problems of high cost, easy grain growth, unfriendly environment, etc., to reduce complexity and cost, and avoid nano agglomeration , the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

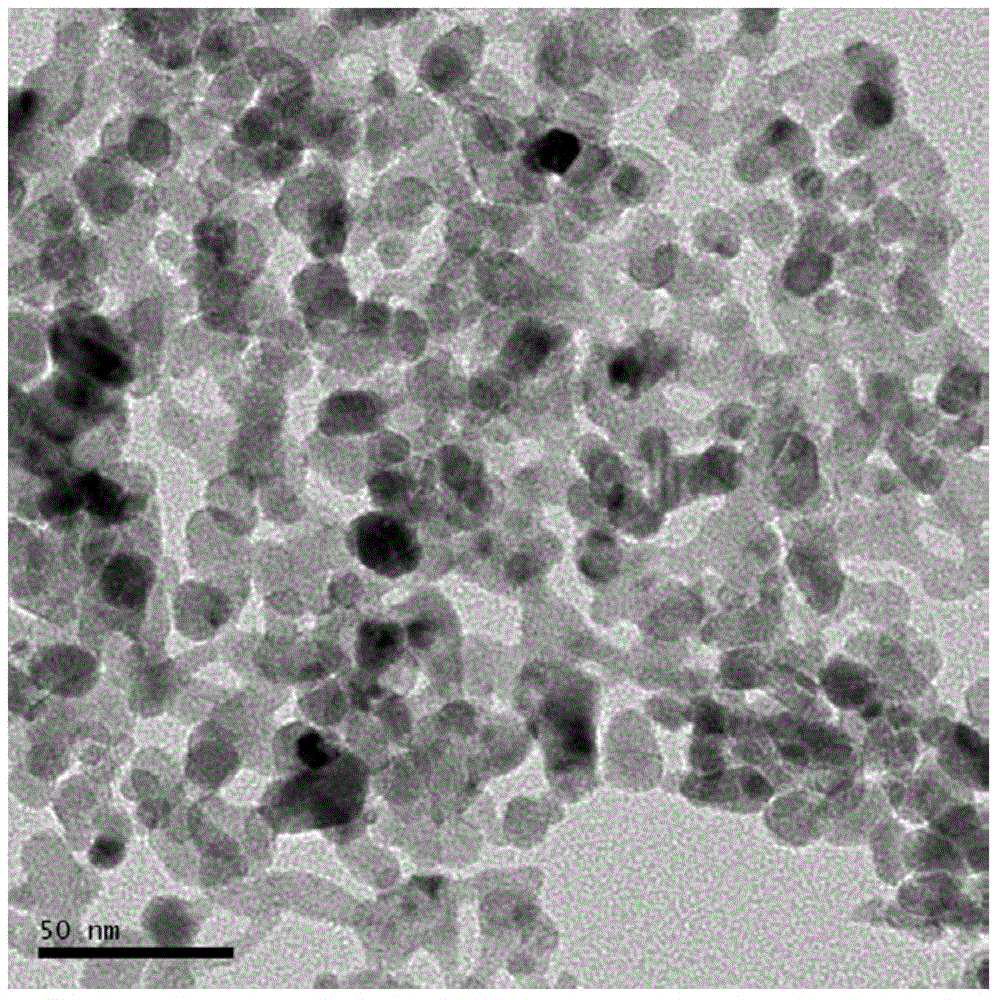

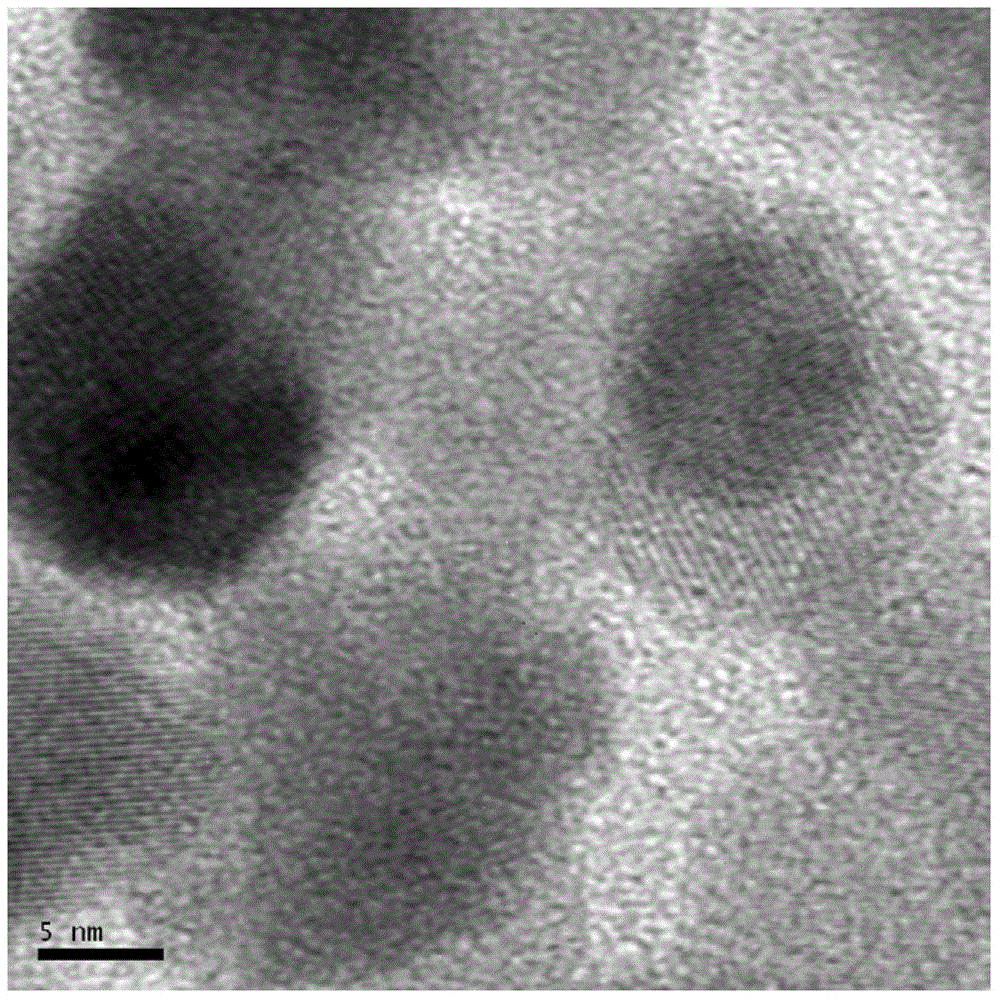

[0020] Mesoporous Nano FeCoO x Preparation of complexes. First, 10 grams of iron isopropoxide, 20 grams of cobalt isopropoxide and 200 grams of polyethylene glycol (10000 molecular weight) are dispersed in 500 grams of heptane organic solvent to obtain a mixed solution. At 100 ° C, water vapor is mixed with The liquid phase is in contact, so that the iron isopropoxide and cobalt isopropoxide in the mixed liquid are hydrolyzed in the polymer network at the same time to obtain nano-FeCoO x / polyethylene glycol polymer complex precursor. After drying in air, the precursor was calcined at 600°C for 6 hours to obtain FeCoO with a particle size of 5 nm and a mesopore distribution of 5 nm. x Complex.

Embodiment 2

[0022] Mesoporous Nano FeCoO x Preparation of complexes. First, iron isopropoxide, cobalt isopropoxide and polyethylene glycol (10000 molecular weight) are dispersed in heptane to obtain a mixed solution. The molar ratio of Fe:Co in the mixed solution is 1:1; the total molar amount of iron and cobalt in the mixed solution The molar ratio of number to polymer is 1:1. The ratio of the total moles of iron and cobalt to the organic solvent is 1:10. At 100°C, water vapor is brought into contact with the mixed liquid, so that the iron isopropoxide and cobalt isopropoxide in the mixed liquid are simultaneously hydrolyzed in the polymer network to obtain nano-FeCoO x / polyethylene glycol polymer complex precursor. After drying in air, the precursor was calcined at 600°C for 6 hours to obtain FeCoO with a particle size of 5 nm and a mesopore distribution of 5 nm. x Complex. Mesoporous Nano FeCoO x The energy spectrum of the complex shows that the products co-exist FeO x with CoO...

Embodiment 3-7

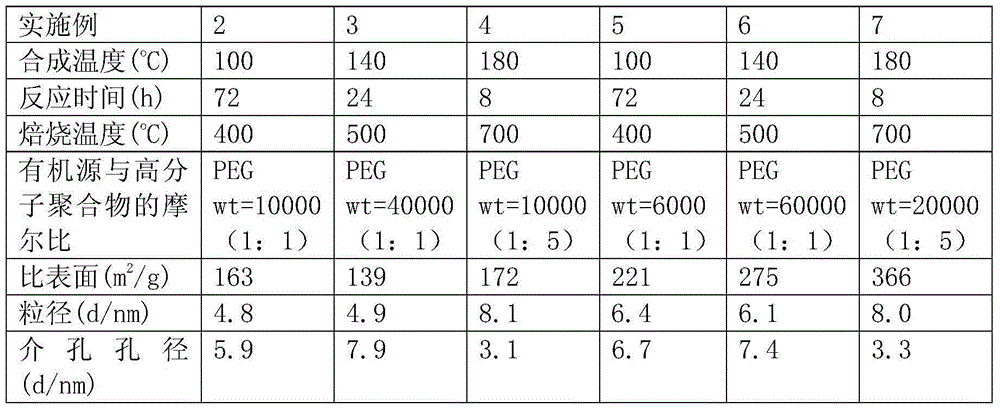

[0024] According to the method of Example 2, the type of polymer added is fixed, the amount of polymer added and the reaction conditions are changed, and the nano-FeCoO x The particle size and mesoporous distribution of the compound are adjusted to obtain mesoporous nano-FeCoO with different particle sizes and different mesoporous distributions. x . The specific results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com