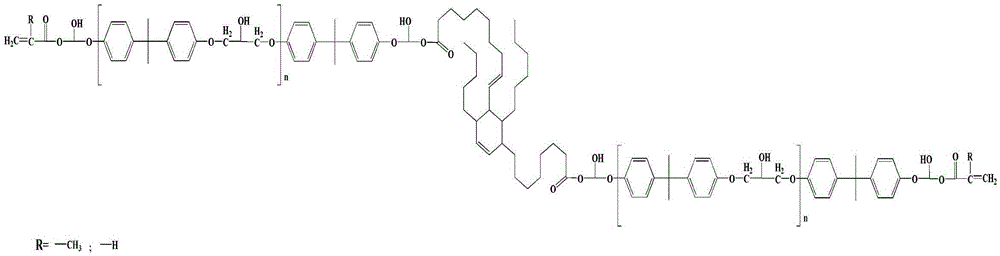

Dimer acid modified epoxy resin and preparation method therefor

A technology of epoxy resin and dimer acid, which is applied in the preparation of carboxylic acid esters, preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of toughening effect, curing rate and hardness to be improved, so as to improve flexibility, Low irritation, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

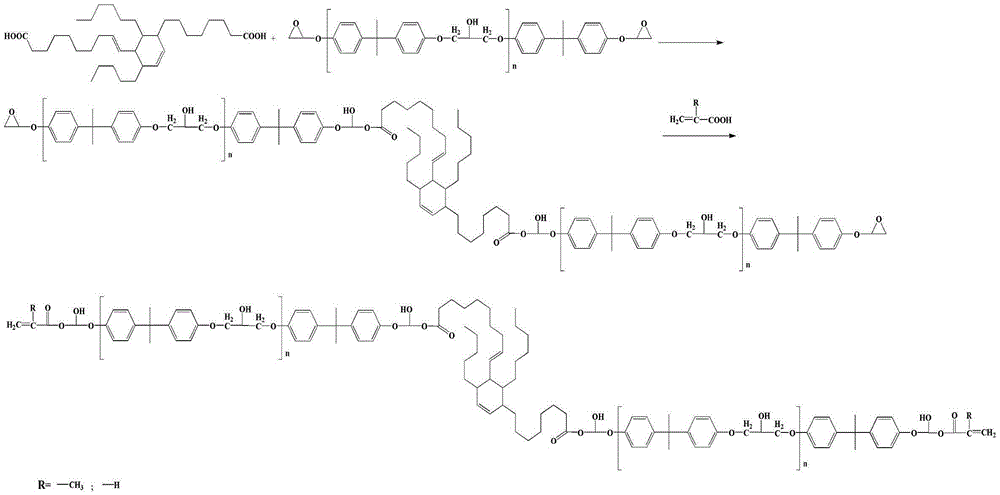

Method used

Image

Examples

Embodiment 1

[0022] Weigh 100g of bisphenol A epoxy resin E51 in a three-necked flask, add 71.4g of dimer acid (dimer is 80wt%, trimer is 20wt%, carboxyl content is 0.35mol / 100g), and feed dry nitrogen , heat up to 100°C, and add 5ml of 1,4-dioxane; after the temperature is kept stable, add 1g of catalyst tetrabutylammonium bromide, stop feeding nitrogen, and react until the acid value of the system is less than 30mgKOH / g, Add 0.09 g of polymerization inhibitor p-hydroxyanisole, 0.01 g of copper chloride, and 18 g of acrylic acid to the system, and stop the reaction when the acid value of the system is less than 10 mgKOH / g to obtain the product. The test viscosity is 25000mPa·s (60°C).

Embodiment 2

[0024] Weigh 100g of bisphenol A type epoxy resin E51 in a three-necked flask, add 109.3g of dimer acid (dimer is 80wt%, trimer is 20wt%, carboxyl content is 0.35mol / 100g), and feed dry nitrogen , heat up to 100°C, and add 5ml of 1,4-dioxane; after the temperature is kept stable, add 1.5g of catalyst tetrabutylammonium bromide, stop feeding nitrogen, and react until the acid value of the system is less than 30mgKOH / g , add 0.05 g of polymerization inhibitor p-hydroxyanisole, 0.005 g of copper chloride, and 9.18 g of acrylic acid to the system, and stop the reaction when the acid value of the system is less than 10 mgKOH / g to obtain the product. The test viscosity is 20000mPa·s (60°C).

Embodiment 3

[0026] Weigh 100g of bisphenol A type epoxy resin E51 in a three-necked flask, add 71.4g of dimer acid (the dimer is 95wt%, the trimer is 5wt%, the carboxyl content is 0.35mol / 100g), and feed dry nitrogen , the temperature was raised to 105°C, and 5ml of 1,4-dioxane was added; after the temperature was kept stable, 1g of catalyst tetrabutylammonium bromide was added, and nitrogen gas was stopped, and when the acid value of the system was less than 30mgKOH / g, the system was Add 0.09 g of polymerization inhibitor p-hydroxyanisole, 0.01 g of copper chloride, and 18 g of acrylic acid, and stop the reaction when the acid value of the system is less than 10 mgKOH / g to obtain the product. The test viscosity is 14000mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com