High-gloss spray-coating-free PMMA/ASA alloy resin composition and preparation method thereof

An alloy resin, spray-free technology, applied in the field of high-gloss spray-free PMMA/ASA alloy resin composition and its preparation field, can solve the problems of unattainable weather resistance, low rigidity, insufficient impact performance, etc., and achieve excellent physical and mechanical properties , low cost, and the effect of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

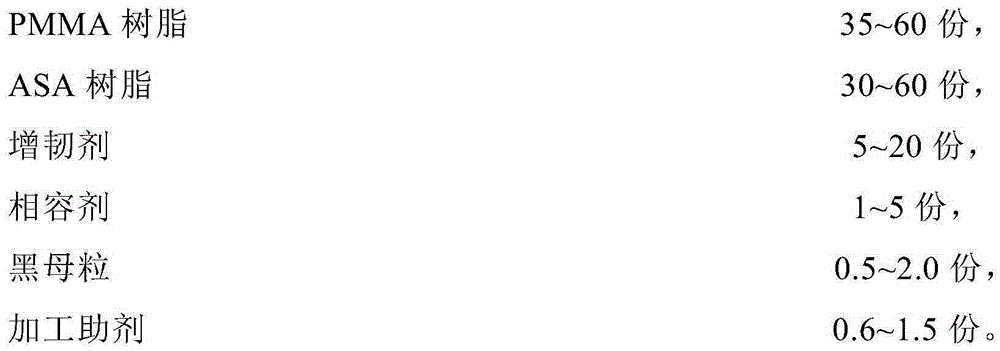

[0029] Raw material composition:

[0030]

[0031] In this example, the compatibilizer is AS-g-MAH, the black masterbatch is polyethylene wax as the carrier, and the processing aid is hindered phenolic antioxidant added at a mass ratio of 2:1:1 , pentaerythritol stearate and silicone mold release agents.

Embodiment 2

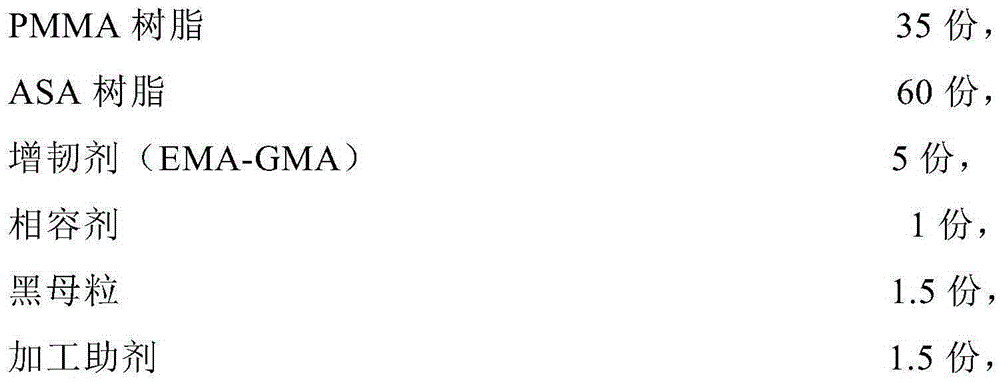

[0033] Raw material composition:

[0034]

[0035] In this example, the compatibilizer is ASA-g-MAH, the black masterbatch is polyethylene wax as the carrier, and the processing aid is phosphite antioxidant added at a mass ratio of 2:1:1. agent, ethylene bis stearic acid amide and silicone mold release agent.

Embodiment 3

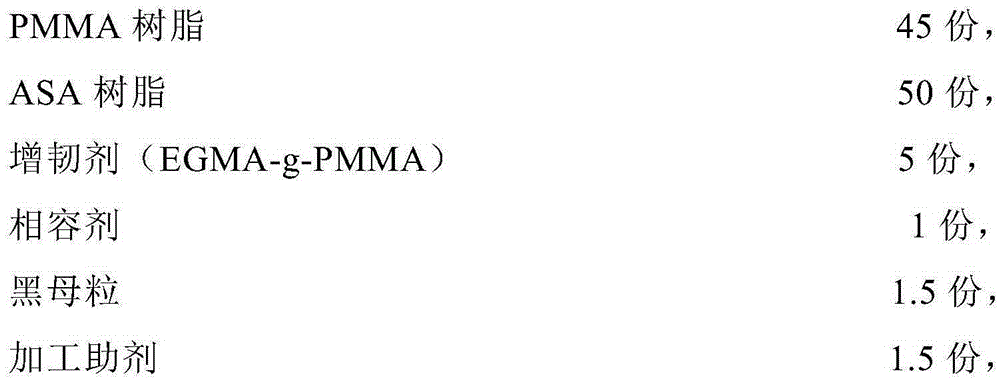

[0037] Raw material composition:

[0038]

[0039] In this example, the compatibilizer is SMA, the black masterbatch is ethylene-vinyl acetate copolymer, and the processing aid is a phosphite antioxidant added at a mass ratio of 2:1:1. , Ethylene bis stearic acid amide and silicone mold release agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular mass | aaaaa | aaaaa |

| Weight average relative molecular mass | aaaaa | aaaaa |

| Molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com