Park grade thermosetting negative ion powdery paint, preparation method and applications thereof

A technology of powder coatings and negative ions, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of difficulty in the release and persistence of negative ion powder coatings, and achieve the effects of ensuring long-term release, improving dispersion, and promoting dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The embodiment of the present invention also discloses the preparation method of the thermosetting anion powder coating of park level as mentioned above, wherein, it adopts following steps:

[0025] A10), all put into mixing tank by the raw material of above-mentioned parts by weight, after extruding through extruder melting, obtain pressing tablet material by turning off fan cooling;

[0026] B10), the tabletting material obtained in the above step A10), first coarsely pulverized and then ground to obtain a fine powder;

[0027] C10), the fine powder obtained in the above step B10) is separated by a cyclone separator, classified and sieved, tested and finished.

[0028] Preferably, the application of the thermosetting negative ion powder coating of the park level as described above, wherein, the thermosetting negative ion powder coating of the park level can be applied in products such as doors, windows, ceilings and the like.

[0029] The embodiment of the present in...

Embodiment 1

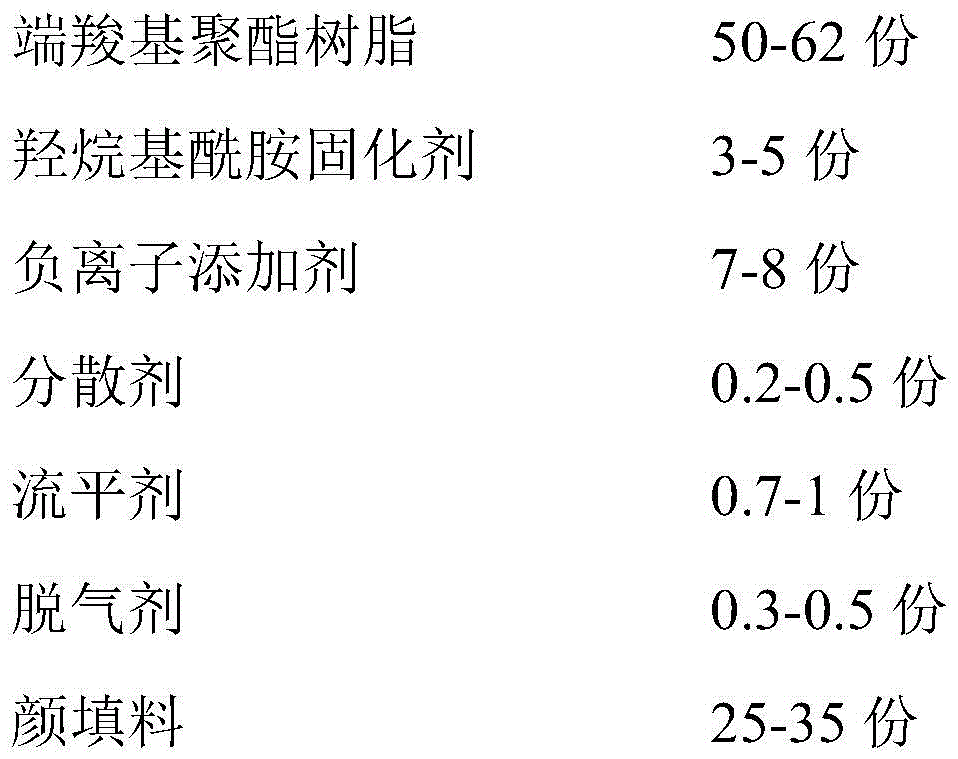

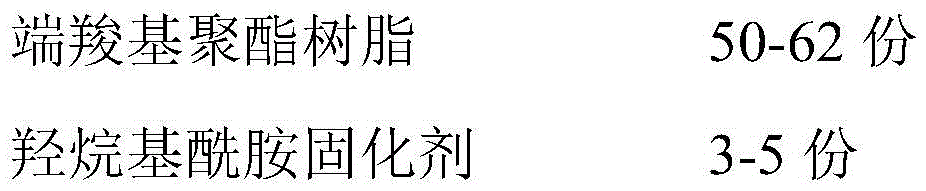

[0031] A kind of thermosetting negative ion powder coating, wherein, it comprises the raw material of following parts by weight:

[0032] 60 parts of carboxyl-terminated polyester resin, specifically, in the present embodiment, the carboxyl-terminated polyester resin adopts UralacP865 produced by DSM Company;

[0033] 3 parts of hydroxyalkylamide curing agent, the acid value range of carboxyl-terminated polyester resin is 30-40, specifically, in this embodiment, the hydroxyalkylamide curing agent adopts NU333 produced by Xinrenkai Company;

[0034] 7 parts of negative ion additives, negative ion additives adopt inorganic mineral matter, specifically, in the present embodiment, negative ion additives adopt the SiO that contains 46% parts by weight 2 , 37% by weight Al 2 o 3 , 11% by weight of B 2 o 3 , 3% by weight TiO 2 , the negative ion additive also includes the Fe of 1% by weight 2 o 3 , the MgO of 1% parts by weight, the LiO of 0.5% parts by weight, the MnO of 0.5%...

Embodiment 2

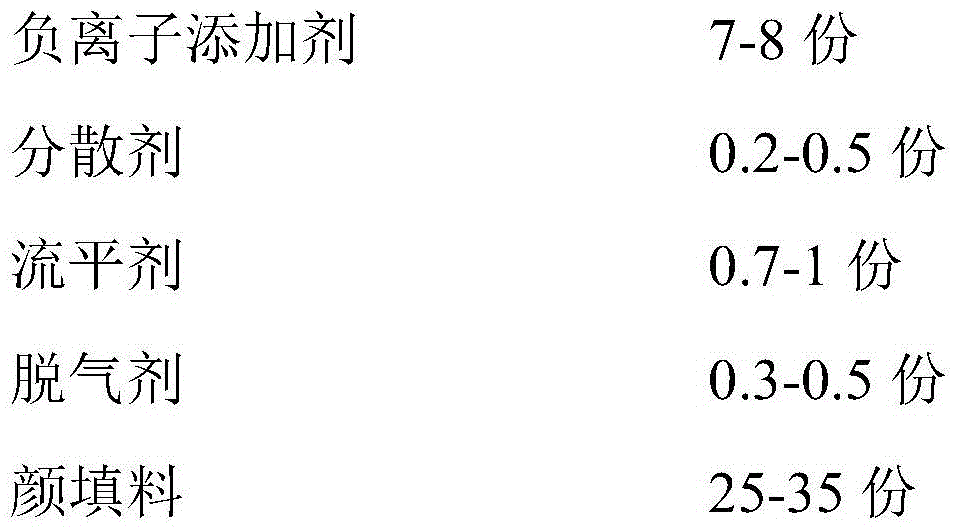

[0048] In present embodiment 2, thermosetting negative ion powder coating comprises the raw material of following parts by weight:

[0049]

[0050]

[0051] The remaining technical solutions of this embodiment 2 are the same as those of the above-mentioned embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com