Preparing method for novel ship propeller

A marine propeller, a new type of technology, applied in the direction of rotating propellers, rotary propellers, etc., can solve the problems affecting the performance and life of the propeller, and insufficient corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

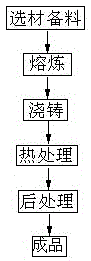

[0016] The specific preparation steps of the novel marine propeller mentioned in the present invention are as follows:

[0017] a) Material selection and preparation. Raw materials are composed of metal materials and auxiliary materials. Metal materials include: pure aluminum, pure iron, pure zinc, pure nickel, pure manganese, pure molybdenum, pure tin, pure chromium and pure copper, and their percentage ratios For: Al9%, Fe4.5%, Zn0.04%, Ni5.5%, Mn2.5%, Mo0.02%, Sn0.03%, Cr3.5%, the balance is Cu; auxiliary materials include covering agent and Refining agent, its content is about 0.9% of the total metal material, the ratio of the two is about 5:1, the covering agent is charcoal, and the refining agent is sodium carbonate;

[0018] b) Melting, the equipment uses a crucible melting furnace, and the melting process is as follows: first, preheat the crucible furnace, and the preheating temperature is controlled at about 600°C; then, add pure iron, pure nickel, pure manganese, pur...

Embodiment 2

[0023] The specific preparation steps of the novel marine propeller mentioned in the present invention are as follows:

[0024] a) Material selection and preparation. Raw materials are composed of metal materials and auxiliary materials. Metal materials include: pure aluminum, pure iron, pure zinc, pure nickel, pure manganese, pure molybdenum, pure tin, pure chromium and pure copper, and their percentage ratios For: Al10%, Fe5%, Zn0.03%%, Ni5.3%, Mn2.6%, Mo0.025%, Sn0.035%, Cr3.3%, the balance is Cu; auxiliary materials include covering agent and refining agent, its content is about 1% of the total metal material, the ratio of the two is about 5:1, the covering agent is charcoal, and the refining agent is sodium carbonate;

[0025] b) Melting, the equipment uses a crucible melting furnace, and the melting process is as follows: first, preheat the crucible furnace, and the preheating temperature is controlled at about 600°C; then, add pure iron, pure nickel, pure manganese, pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com