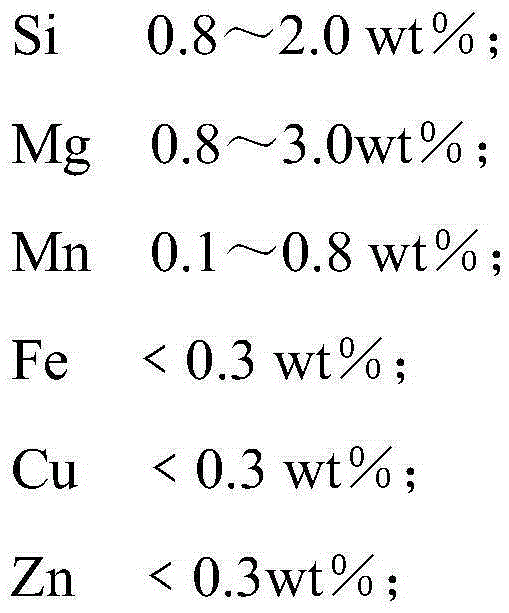

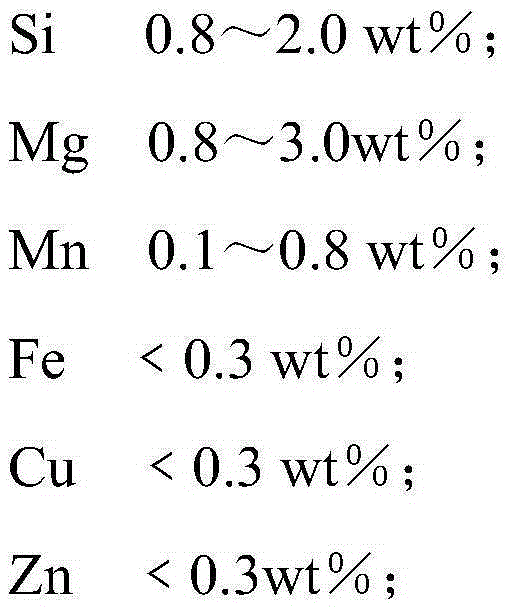

Cast aluminum alloy capable of being anodized and preparation method thereof

A technology of casting aluminum alloy and anodizing, applied in the field of casting aluminum alloy and its preparation, and aluminum alloy, can solve the problems of poor color and luster, inability to guarantee the effect, low film thickness, etc., and achieve high strength, formability, and oxidation effect. Better, even color results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Si: 8kg, Mg: 8kg, Mn: 1kg, Al: 983kg are put into the melting furnace for melting, and the melting temperature is 700~730℃;

[0039] Degassing and refining: adjust the smelting temperature to 700-720°C, add hexachloroethane for degassing and refining, the addition amount is 0.4%, stir evenly for 10 minutes, and then purify and remove slag;

[0040] Modification and secondary refining: adjust the melting temperature to 730-740 °C, add Al-Sr modification agent for modification treatment, after adding for 30 minutes, adjust the melting temperature to 700-710 °C, add degassing refining agent, the addition amount is 0.1%, and stir evenly for 10 min , then remove the slag and prepare for pouring;

[0041] Pouring and casting: adjust the alloy temperature at 680-720°C, and the mold temperature at 180-250°C.

[0042] The mechanical properties of the obtained alloy are: the tensile strength is 300MPa, the elongation is 10%, and the yield strength is 210MPa.

Embodiment 2

[0044] Si: 20kg, Mg: 30kg, Mn: 8kg, Fe: 3kg, Cu: 3kg, Zn: 3kg, Al: 933kg are put into the melting furnace for melting, and the melting temperature is 700~720℃;

[0045] Degassing and refining: adjust the smelting temperature to 700-720°C, add hexachloroethane for degassing and refining, the addition amount is 0.5%, stir evenly for 20 minutes, and then purify and remove slag;

[0046] Modification and secondary refining: adjust the melting temperature to 730-740°C, add Al-Sr modifier for modification treatment, after adding for 20 minutes, adjust the melting temperature to 700-720°C, add degassing refining agent, the addition amount is 0.2%, and stir evenly for 8 minutes , then remove the slag and prepare for pouring;

[0047] Pouring and casting: adjust the alloy temperature at 680-720°C, and the mold temperature at 180-250°C.

[0048] The mechanical properties of the obtained alloy are: the tensile strength is 290MPa, the elongation is 5%, and the yield strength is 230MPa. ...

Embodiment 3

[0050] 1 ton of aluminum alloy material with a domestic brand of 6061, take a piece to test the silicon content in it, after getting the test value, put the aluminum alloy with a domestic brand of 6061 into the aluminum melting furnace, and then add it to the aluminum melting furnace after the aluminum alloy is melted Silicon or aluminum-silicon alloy, so that the silicon content in the aluminum alloy in the hot-melt state is 0.8-2.0%, and the melting temperature is 700-750°C;

[0051] Degassing and refining: adjust the smelting temperature to 700-720 °C, add hexachloroethane for degassing and refining, the addition amount is 0.2%, stir evenly for 15 minutes, and then purify and remove slag;

[0052] Modification and secondary refining: adjust the melting temperature to 730-750 °C, add Al-Sr modification agent for modification treatment, after adding for 10 minutes, adjust the melting temperature to 700-720 °C, add degassing refining agent, the addition amount is 0.3%, and stir e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com