Dynamic visualization observing device for displacement experiment

A technology of displacement experiment and observation device, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc. It can solve problems that affect observation results, rock cores are not fixed, and it is difficult to form grooves, etc., so as to improve economic efficiency. Benefits, enhanced oil recovery, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

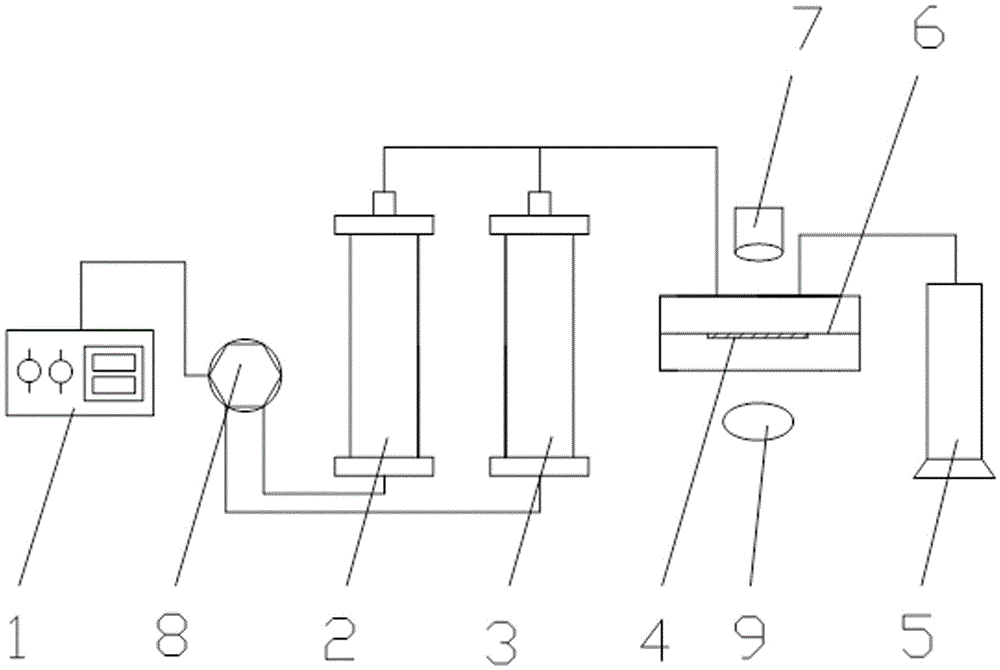

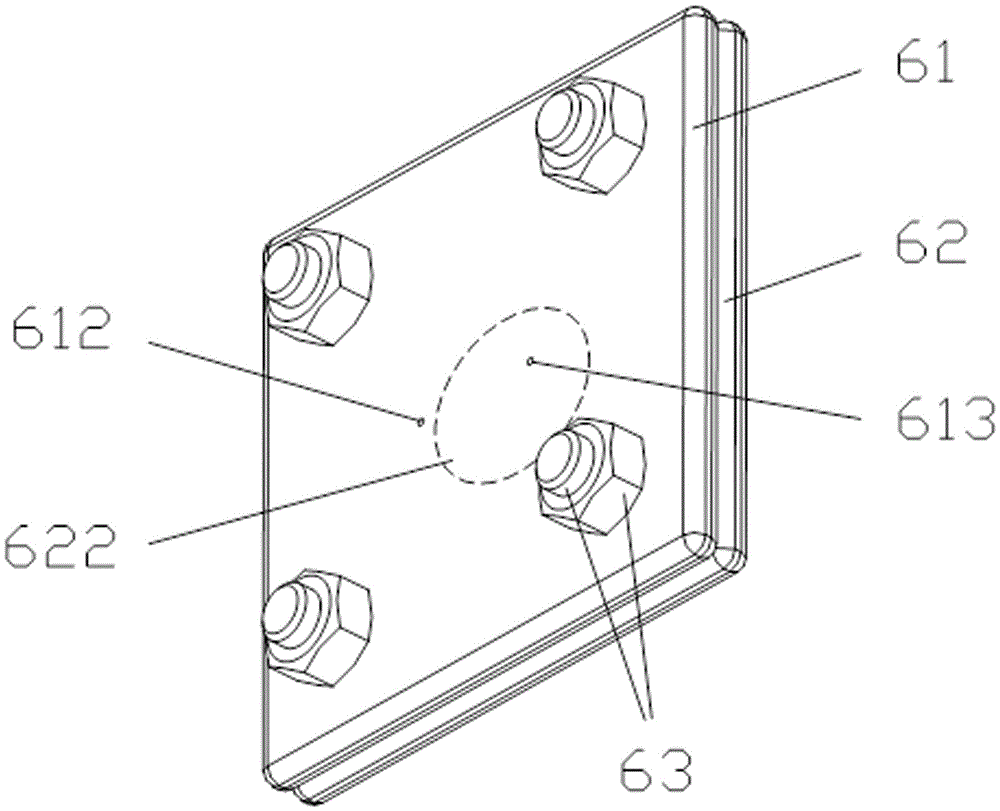

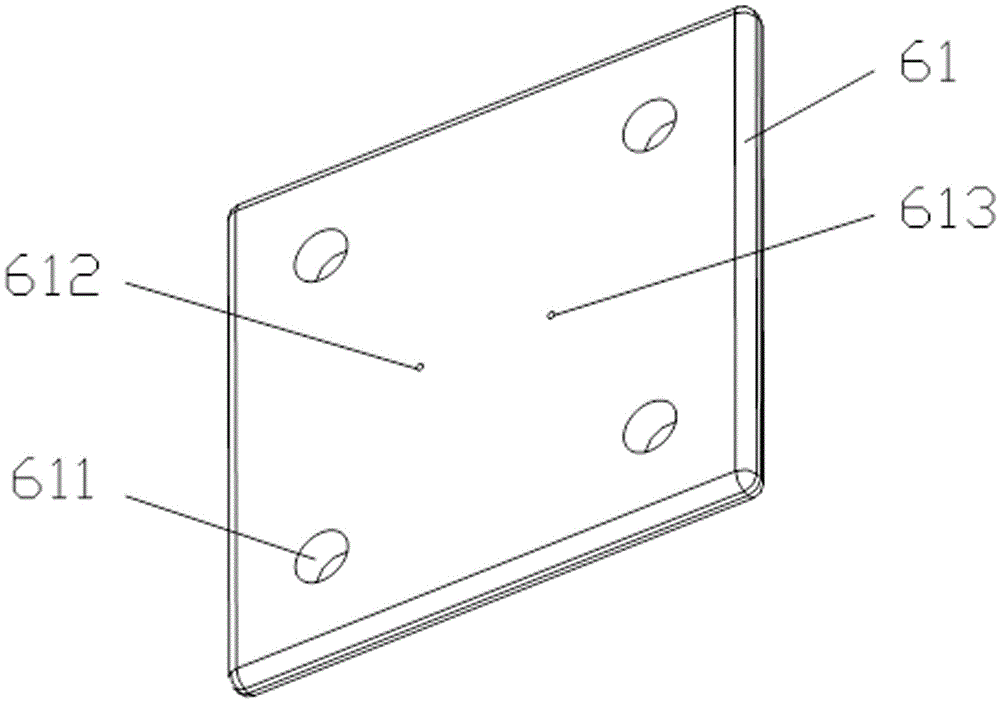

[0041] Such as figure 1 As shown, according to an embodiment of the dynamic visualization observation device for displacement experiments of the present invention, it includes a fluid pumping device 1, an intermediate piston container I2, an intermediate piston container II3, rock core slices 4 and a liquid collection container 5. The intermediate piston container I2 and the intermediate piston container II3 are connected in parallel between the fluid pumping device 1 and the core slice 4, and also include a dynamic visual microscopic model 6 and an observation component 7, and the core slice 4 is placed Inside the dynamic visualization micro-model 6 .

[0042] The rock core slices are fixed by a dynamic visualized microscopic model to simulate microscopic reservoir conditions. The middle piston container I is filled with oil, and the middle piston container II is filled with oil displacement system (water). The fluid pumping device is an advection pump. Inject oil from the...

Embodiment 2

[0058] According to another embodiment of the dynamic visualization observation device for displacement experiments of the present invention, its structure, connection relationship between various components, working principle and beneficial effects, etc. are all the same as Embodiment 1, the difference is: The length of the body and the lower body of the model are both 150mm, the width is 150mm, and the thickness is 10mm. The diameter of the bolt hole of the upper body of the model and the lower body of the model is 15mm. The diameter of the oil-water injection port and the liquid discharge port are both 5mm, and the distance from the center of the upper body of the model is 20mm. After the core sheet is pressed and embedded, the groove formed in the center of the lower body of the model is circular in shape, with a diameter of 60mm and a depth of 0.1mm. The thickness of the core slices is 0.1mm.

[0059] The dynamic visual observation method used in the displacement experim...

Embodiment 3

[0061] According to another embodiment of the dynamic visualization observation device and method for displacement experiments of the present invention, its structure, process steps, working principle and beneficial effects are all the same as those of Embodiment 1, the difference is: After inserting the model lower body, directly use the model upper body to press on the rock core sheet until the model upper body and the model lower body are pressed together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com