Low-temperature explosion-proof turbocharger

A turbocharger, explosion-proof technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., to increase the driving force and reduce the working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

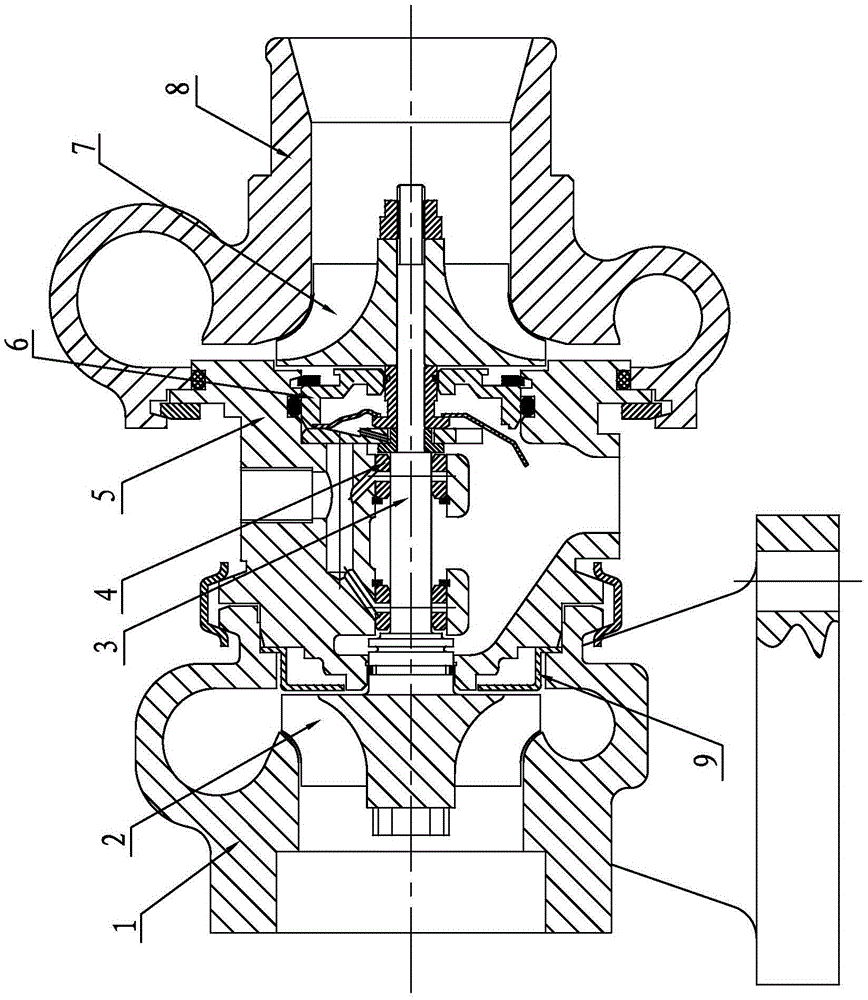

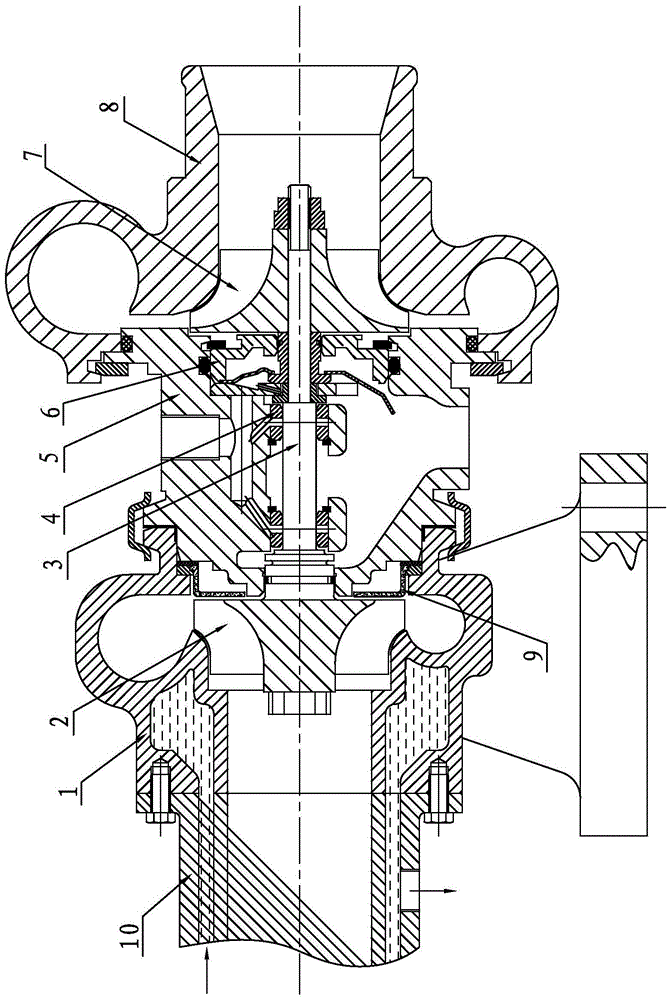

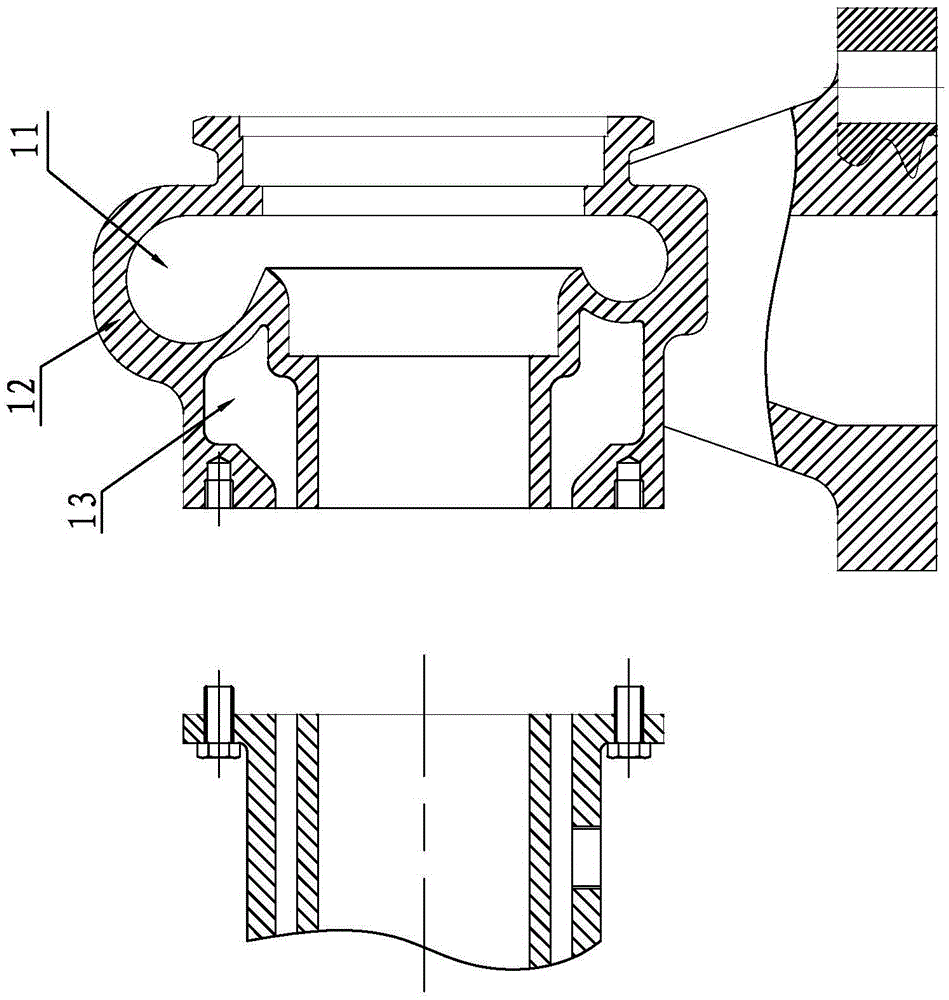

[0025] A low-temperature explosion-proof turbocharger, including a turbine casing 1, a turbine 2, a turbine shaft 3, a sliding bearing 4, an intermediate body 5, a diffuser plate 6, a booster impeller 7, a pressure casing 8, a bridge break heat insulation structure 9 and The water-cooled exhaust temperature control pipe 10, the turbine 2 and the booster impeller 7 are respectively installed at both ends of the turbine shaft 3, the turbine 2 is located in the turbine housing 1, the booster impeller 7 is located in the pressure housing 8, and the turbine shaft 3 is passed through two sliding The bearing 4 is installed on the intermediate body 5, the turbine casing 1 is fixedly installed on the left side of the intermediate body 5 through the broken bridge heat insulation structure 9, the pressure shell 8 is fixedly installed on the right side of the intermediate body 5 through the diffuser plate 6, and the intermediate body 5 The lubricating oil passage is connected with the two ...

Embodiment 2

[0026] Embodiment 2: The difference from Embodiment 1 lies in the shape of the inner surface of the cooling water passage 13. In this example, the radial cross-section shape of the cooling water passage 13 in the turbine shell 1 is wave-shaped, which can not only further increase the water and The contact area of the turbine shell can also reduce the residence time of water in the cooling water channel 13, and the cooling effect on the turbine shell is better.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap