Blast construction method of orientation window of thick-wall brick chimney

A construction method and directional blasting technology, applied in blasting and other directions, can solve the problems of high labor intensity, low construction accuracy, poor safety, etc., and achieve the effects of low labor intensity, low overall construction cost, and low mechanical wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

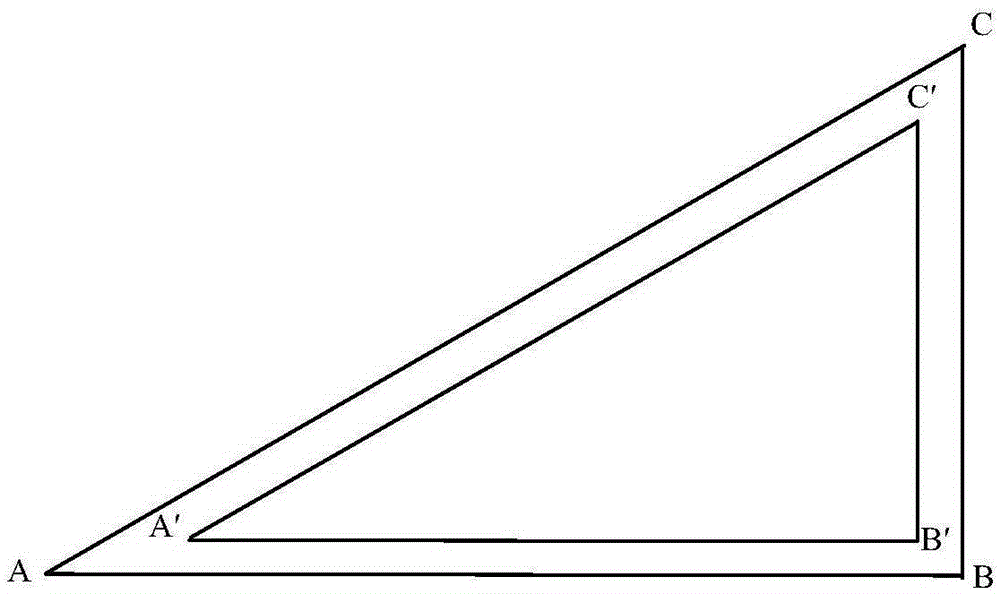

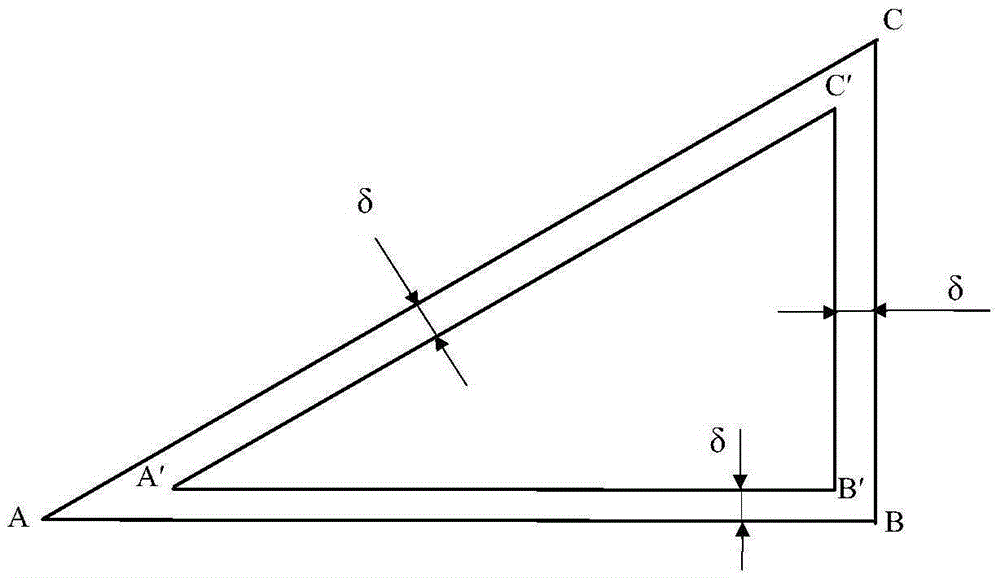

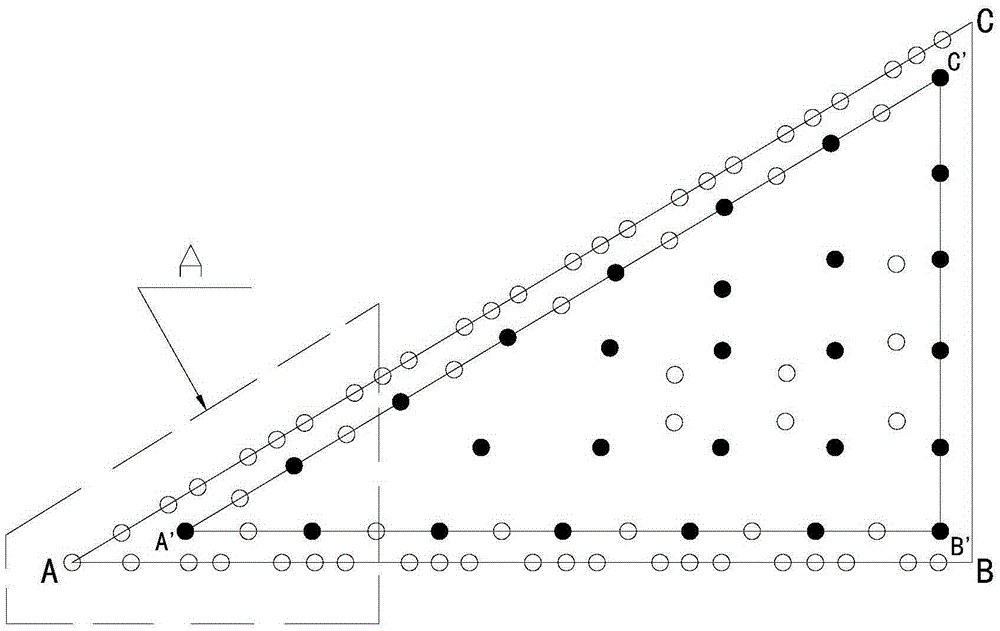

[0040] A method for blasting design and construction of a directional window in a thick-walled brick chimney. The directional window to be excavated is a right triangle ABC. The specific steps are as follows.

[0041]1. Carry out measurement and stakeout according to the blasting cut requirements in the blasting design plan, precisely stake out the specification, size and position of the directional window on the outer wall of the brick chimney, and use a total station for stakeout marking, and use the total station to self-orientate the top of the window The corners are marked point by point, including marking the three vertices and boundary lines of the directional window, and marking the three vertices and side lines of the triangular blasting area A'B'C'. The triangular directional window ABC, the triangular blasting area A′B′C′ and the thickness δ of the blasting protection layer are as follows: figure 1 , figure 2 shown.

[0042] 2. When the total station is staked ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com