Vibronic Sensor

A vibration unit and mechanical vibration technology, applied in the direction of instruments, scientific instruments, engine components, etc., can solve complex problems, achieve the effect of reducing power consumption and simplifying calculation work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

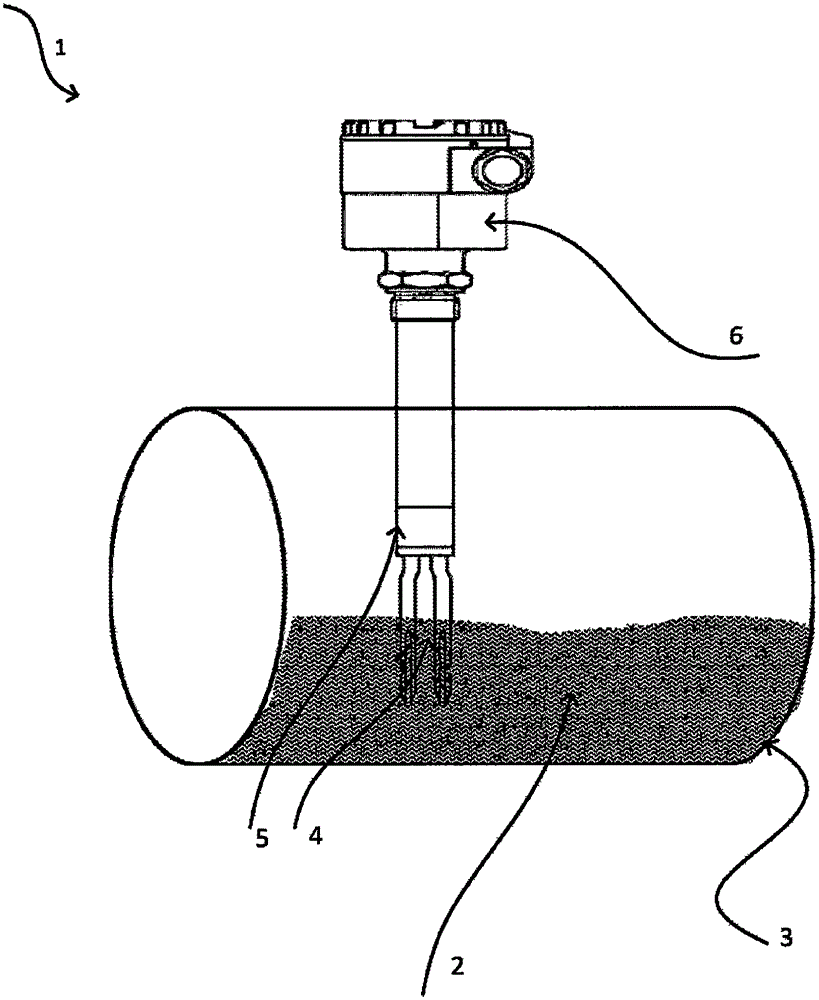

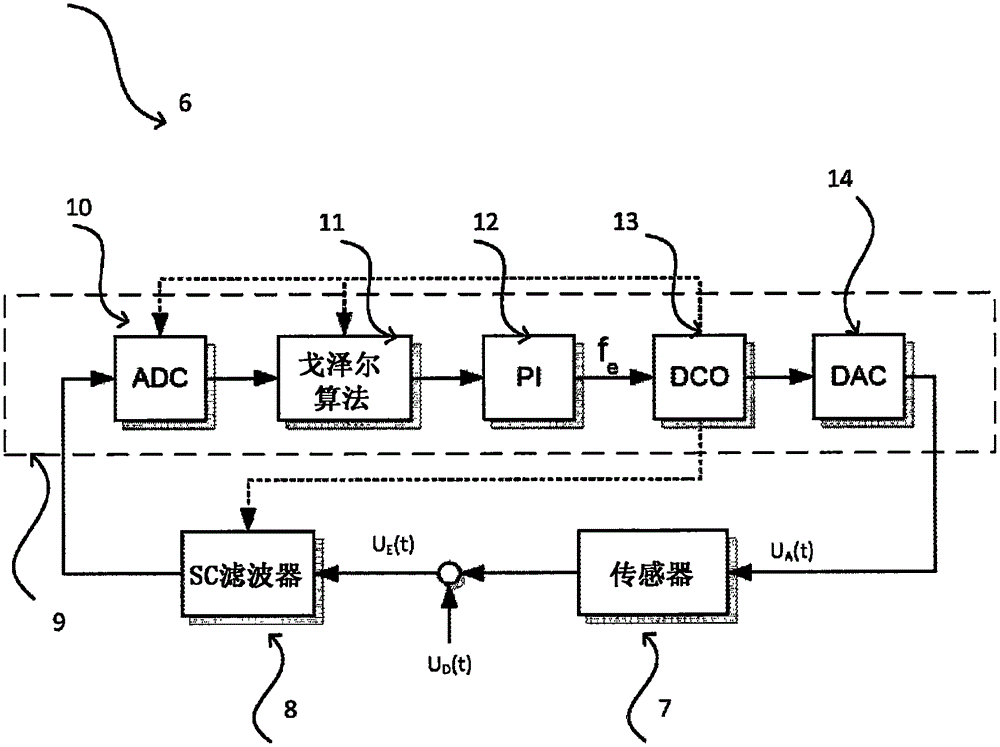

[0063] Electronic vibration sensor 1 in figure 1 shown in . The vibratable unit 4 is represented in the form of an oscillating tuning fork, which is partially immersed in the medium 2 located in the container 3 . The vibratable unit is excited by the electromechanical transducer unit 5 to vibrate mechanically, for example, it may be a piezoelectric stack actuator or a coupling actuator. However, it is naturally understood that other embodiments of the electronic vibration sensor also fall within the protection scope of the present invention. Furthermore, the electronics unit 6 is represented by means by which signal evaluation and / or signal feedback can take place. The essential device block diagram of the electronic unit according to the present invention is figure 2 Theme of.

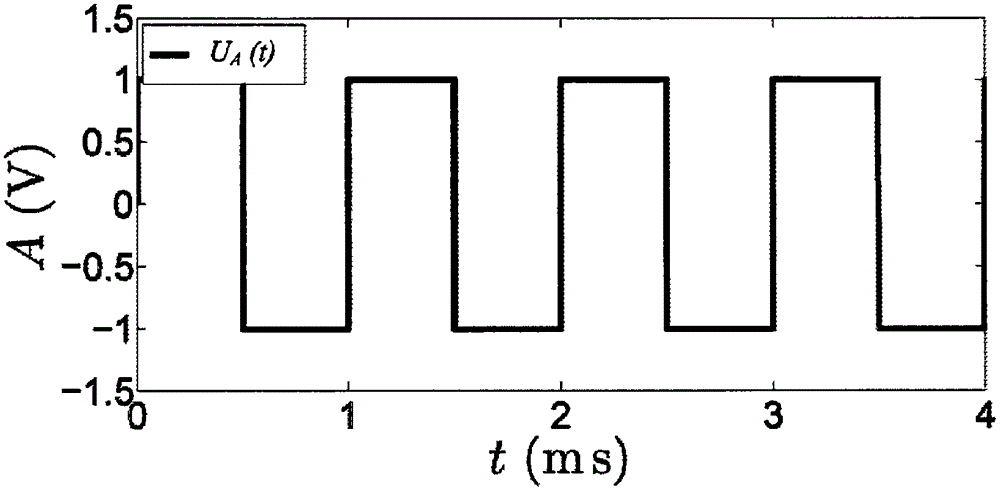

[0064] sensor element 7, consisting of figure 1 The vibratable unit 4 and the electromechanical transducer unit 5 are provided with an excitation signal U A . Conversely, from the mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com