In-situ test device and method for settling and precipitating process of aquatic particles

An in-situ test and deposition process technology, applied to the analysis of materials, instruments, etc., can solve the problems of inability to reflect the environmental information of particle stratification, destroy the characteristics of particle layer deposition, and short capture time, so as to achieve simple structure and easy processing , good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

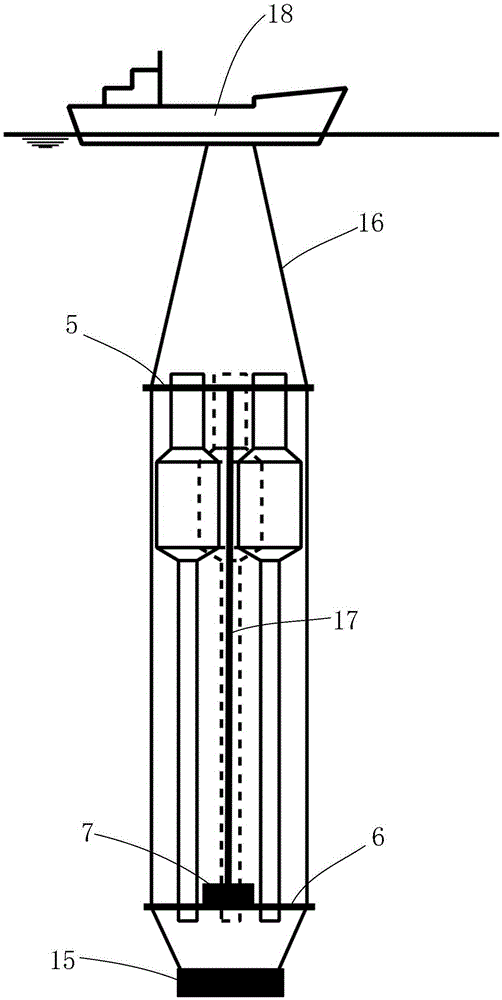

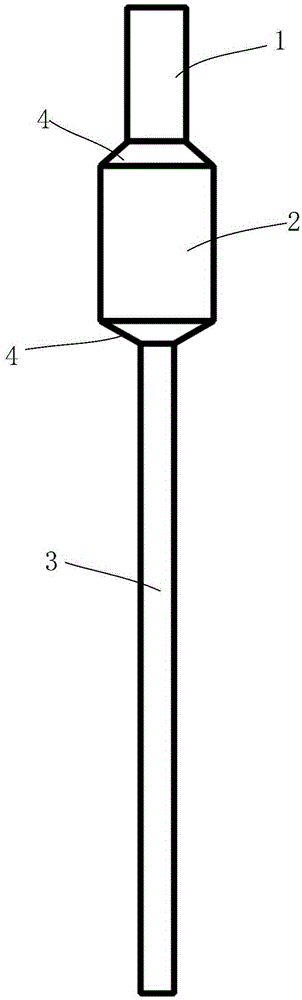

[0080] According to the above-mentioned invention, an in-situ test observation is carried out in a water area in the Three Gorges Reservoir area of the Yangtze River by using a set of in-situ test devices. Among them, the three sets of dustfall traps are all 2.0m in height, integrated and fixed on the support mechanism to form a complete set of dustfall traps. Among them, the diameter of the entrance zone 1 is 0.15m, and the height is 0.2m; the diameter of the settlement zone 2 is 0.3m, and the height is 0.3m; the diameter of the sedimentation zone is 0.1m, and the height is 1.5m.

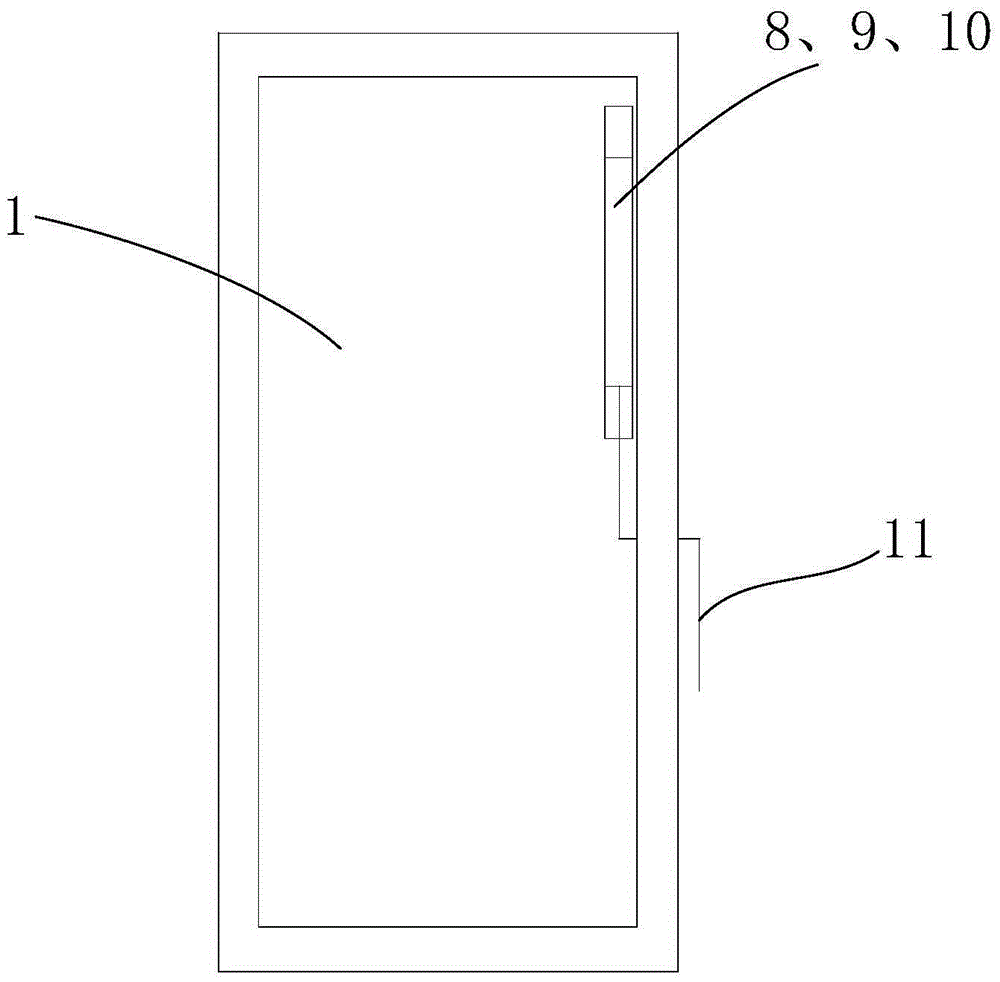

[0081] There are two real-time monitoring probes for water temperature and dissolved oxygen in the inlet section and the sedimentation section of the sedimentation particle trap, and one set of probes in the sedimentation area is located at the bottom of the device. The data collection frequency is once every 24 hours, and the release time of the device is 3 months (June to August), a total of 90...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com