Resolution ratio performance measuring device of cone beam CT and calibration method

A technology of measuring device and calibration method, which is applied in the directions of measuring device, analyzing materials, and using radiation for material analysis, etc., can solve the problems of being easily affected by human factors, complex manufacturing process, and discrete, etc., and achieves low manufacturing cost and easy implementation. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the embodiments and with reference to the accompanying drawings.

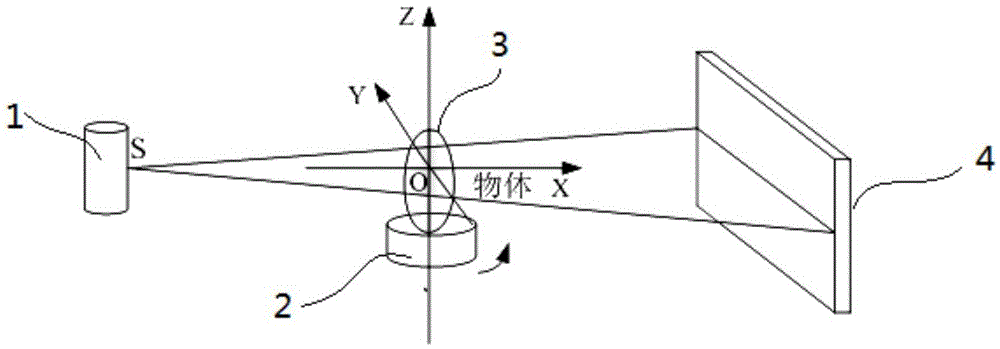

[0057] See figure 1 . figure 1 It embodies the coordinate system of the cone beam CT system, wherein the cone beam CT system mainly includes the main components such as the ray source 1, the rotating table 2, and the flat panel detector 4, and the plane SOZ formed by the focus S of the ray source and the rotation axis is perpendicular to the plane of the detector 4, and The projection of the focal point on the detector 4 is located at the center of the detector 4 . The object is placed on the turntable 2, and the turntable 2 rotates around the Z axis to realize the acquisition of cone beam CT projection data.

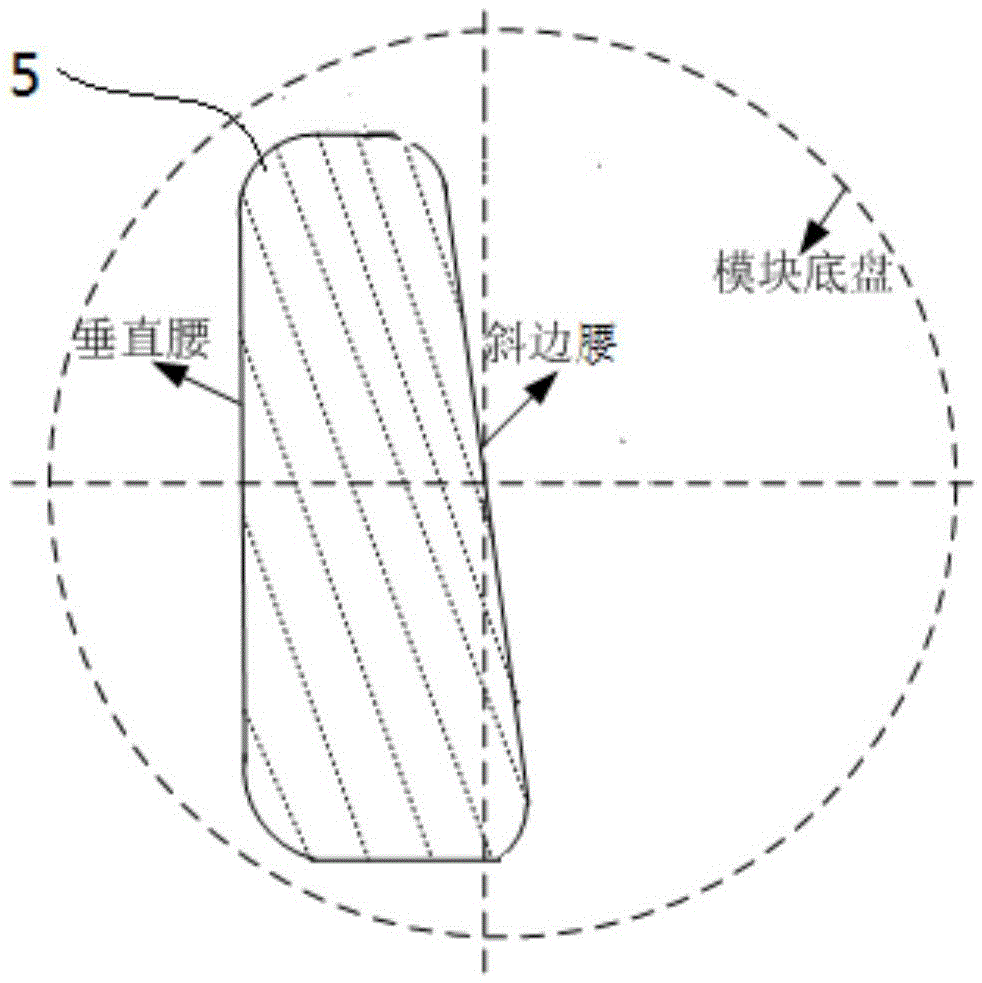

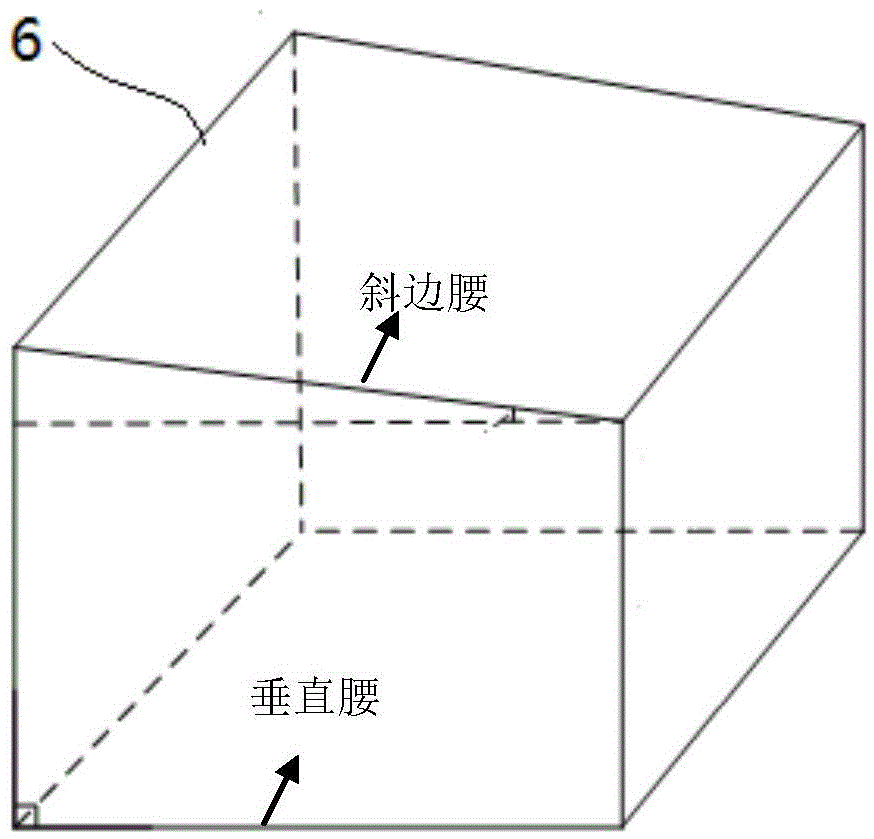

[0058] See figure 2 . Schematic diagram of the cross-section of the lateral resolution measurement module. The cross-section is trapezoidal, one of the waists of the trapezoid is perpendicular to the upper and lower bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com