Iron core remanent magnetism elimination and measurement method based on polarity-reversal DC voltage source

A technology of DC voltage source and polarity reversal, which is applied in the direction of the magnitude/direction of the magnetic field, circuits, magnetic objects, etc., which can solve the problems of inability to measure the residual magnetism value, harsh power requirements, incomplete demagnetization, etc., and achieve the demagnetization effect Good, low power supply, good waveform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in detail:

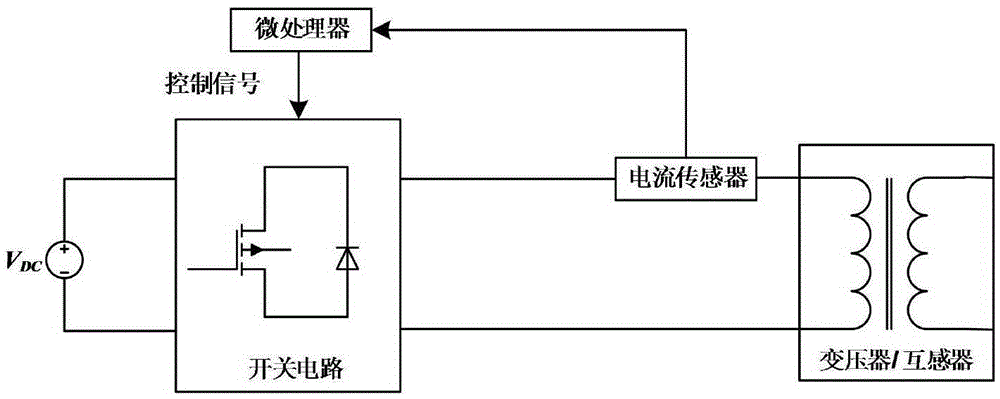

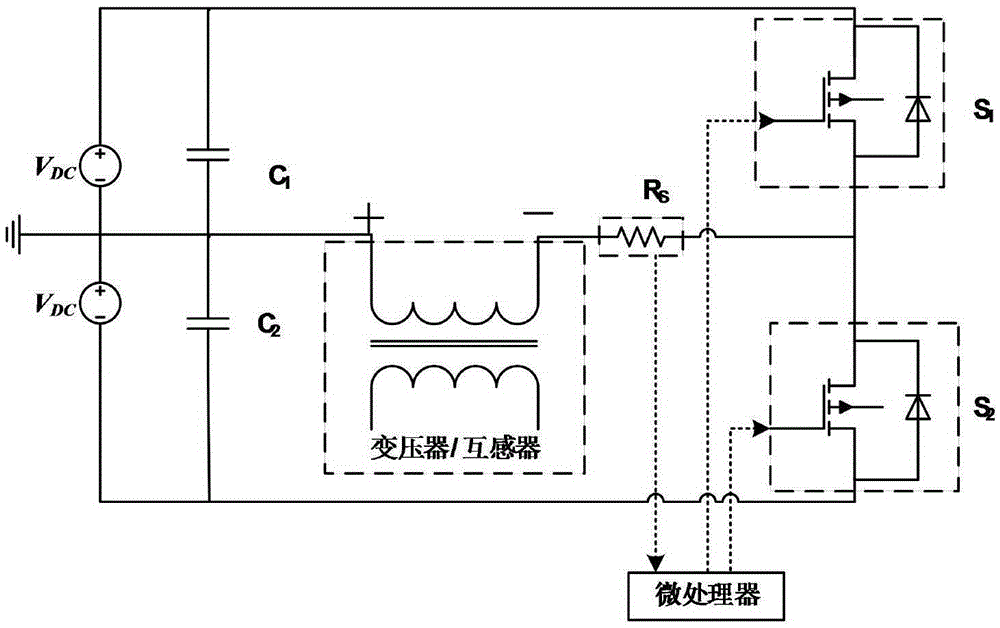

[0031] like figure 1 As shown, the DC voltage source adopts a custom-made voltage adjustable constant voltage source with sufficient power. The switch circuit uses power electronic devices as switches to change the polarity of the DC power supply, and the current sensor uses milliohm-level high-precision non-inductive resistors to reduce losses. The microprocessor mainly controls the switching action according to whether the current in the winding reaches saturation, so as to change the polarity of the voltage applied to both ends of the winding and precisely control its conduction time. Its working process is as follows:

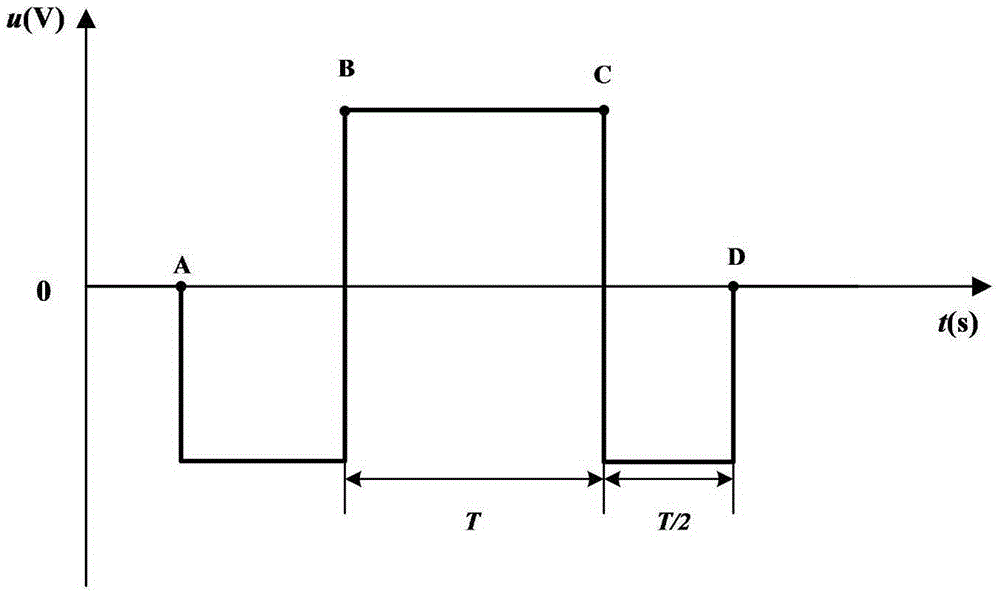

[0032] First, apply a negative DC voltage (-V DC ) to make the iron core reach the negative saturation point; then the microprocessor confirms that the negative saturation current (-I s ), control the switching action, and apply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com