Liquid crystal display panel, manufacturing method thereof and liquid crystal display device

A technology for liquid crystal display panels and liquid crystal display devices, which is applied in the directions of instruments, nonlinear optics, optics, etc., can solve the problems of light source waste, waste, light waste, etc., and achieve the effects of reducing product power consumption, increasing utilization, and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

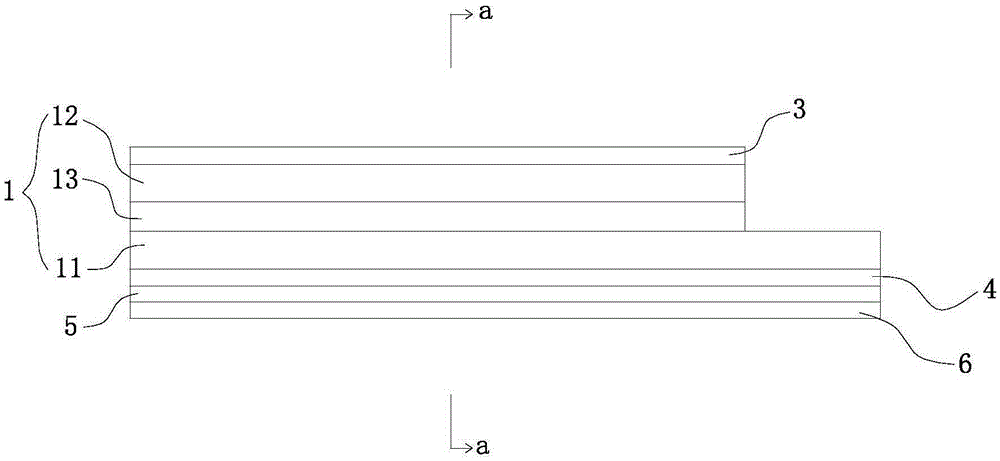

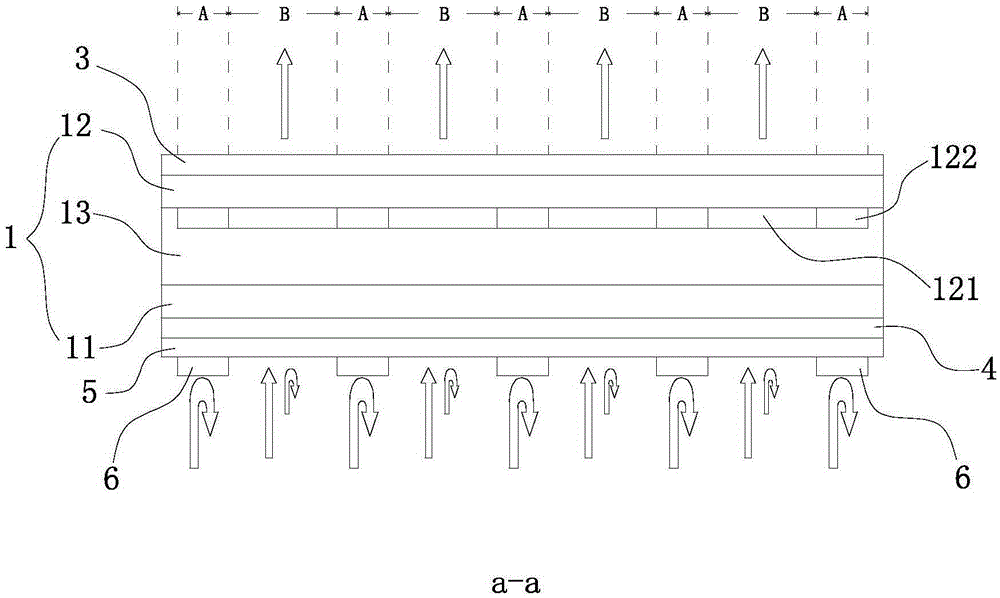

[0031] See figure 2 and image 3 , which respectively show a side view and a schematic cross-sectional structure of the liquid crystal display panel according to the first embodiment of the present invention. In an optional embodiment of the present invention, the liquid crystal display panel includes: a liquid crystal cell 1 , a first absorbing polarizing layer 3 , a second absorbing polarizing layer 4 , a reflecting polarizing layer 5 and a reflecting layer 6 .

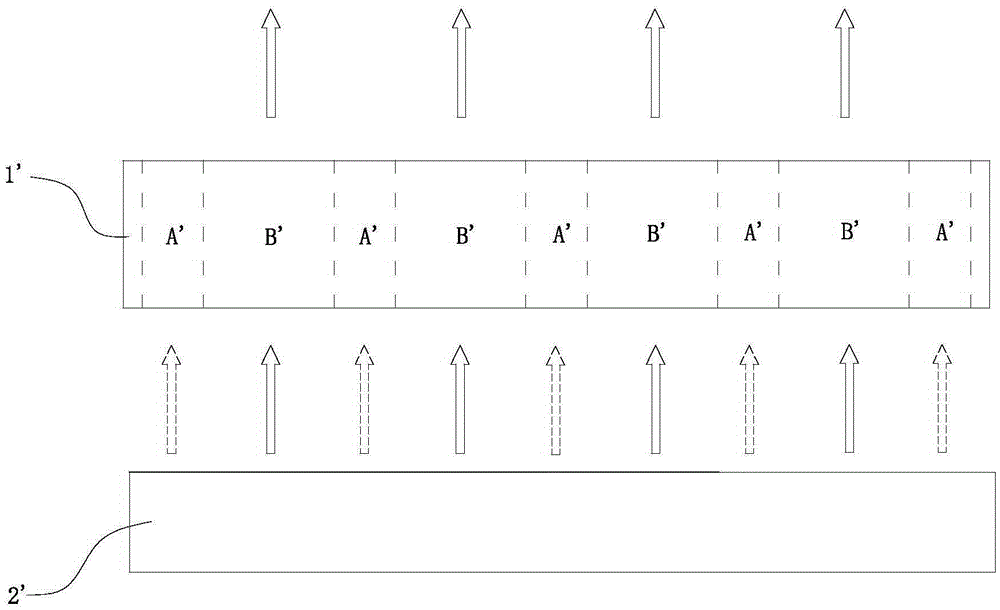

[0032] The liquid crystal cell 1 includes a plurality of light-transmitting regions B (ie, the effective display region of the liquid crystal display panel) and a light-shielding region A surrounding each light-transmitting region B. Such as figure 2 As shown, the liquid crystal cell 1 includes: a first substrate 11 and a second substrate 12 oppositely arranged, and a liquid crystal molecule layer 13 arranged between the first substrate 11 and the second substrate 12 .

[0033]A sub-pixel array formed by a plur...

no. 2 example

[0064] The second embodiment of the present invention is another implementation mode of the liquid crystal display device of the present invention, Figure 12 A side view of the liquid crystal display device described in this embodiment is shown, including figure 2 and image 3 As shown in the liquid crystal display panel, backlight unit 2, drive unit 7 and flexible circuit board 8, optionally, the reflective layer 6 of the liquid crystal display panel in this embodiment is optionally made of a metal material, for example, the reflective layer 6 can be Made of silver, aluminum or their compounds. The difference from the liquid crystal display device described in the first embodiment is that the reflective layer 6 is grounded. Specifically, in Figure 12 In the illustrated embodiment, the reflective layer 6 is electrically connected to the flexible circuit board 8 disposed on the first substrate 11 through a conductive glue 81 . After the reflective layer 6 is electrically...

no. 3 example

[0066] The third embodiment of the present invention is another implementation mode of the liquid crystal display device of the present invention, Figure 13 A side view of the liquid crystal display device described in this embodiment is shown, including figure 2 and image 3 As shown in the liquid crystal display panel, backlight unit 2, drive unit 7 and flexible circuit board 8, optionally, the reflective layer 6 of the liquid crystal display panel in this embodiment is optionally made of a metal material, for example, the reflective layer 6 can be Made of silver, aluminum or their compounds. The reflective layer 6 is grounded. Different from the liquid crystal display device described in the foregoing embodiments, in Figure 13 In the illustrated embodiment, the liquid crystal display device includes a metal frame 9, and the metal frame 9 is located on the outermost side of the liquid crystal display device. Such as Figure 13 As shown, the metal frame 9 is located o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com