Flip-chip eutectic bonding method for chip with medium bridge and obtained product

A eutectic bonding and chip technology, which is used in the manufacture of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., can solve the problem of uneven force on the contact point between the thimble and the chip, difficult to accurately control the thimble pressure, and difficult to position accuracy of the chip. Guarantee and other issues, to achieve the effect of mass assembly, mass assembly, and high-efficiency mass assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

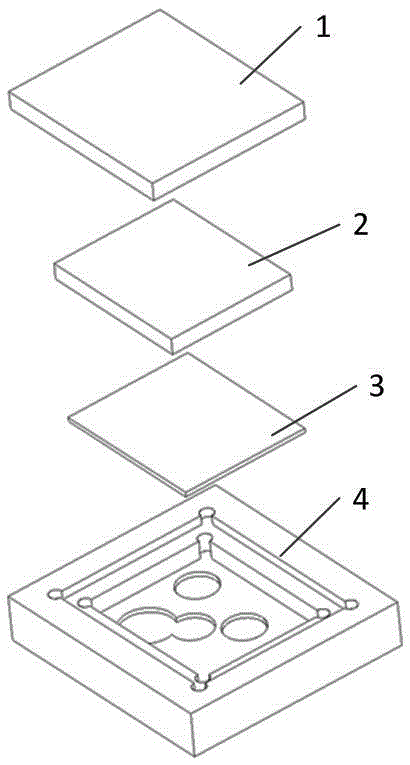

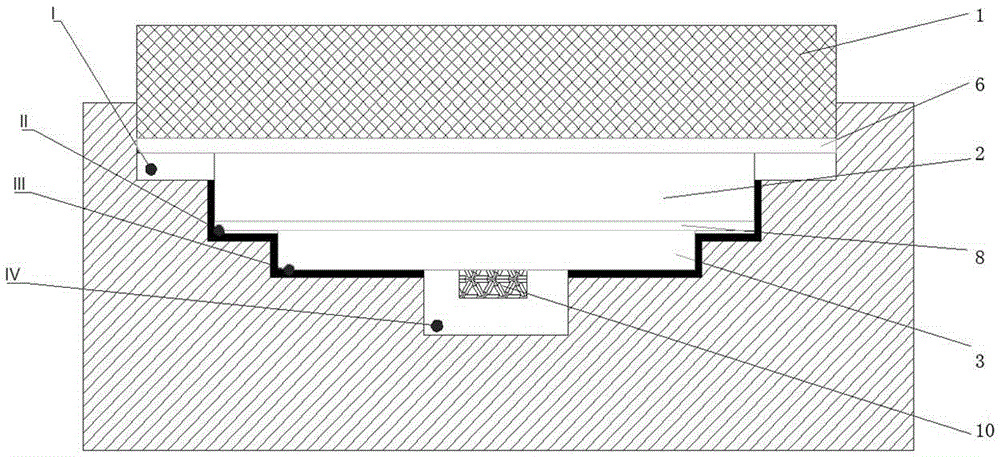

[0094] See figure 1 with figure 2 :

[0095] (1) Forming the base

[0096] Using high-purity graphite precision processing, four-layer cavities are milled by CNC machine tools. Cavity I is opened according to the distribution position of the dielectric bridge on the surface of the chip. Cavity II is used for chip placement and positioning. The cavity size is consistent with the chip eutectic position. The cavity height and chip thickness are 30μm lower. The size of the surface cavity is the same as that of the substrate, and the height is slightly lower than the thickness of the substrate by 30 μm.

[0097] (2) Substrate pretreatment

[0098] The substrate is a high thermal conductivity Mo80Cu20 alloy sheet, which is machined into the required 4mm×6mm×0.5mm, and the surface is plated with Au / Ni plating. The Au80Sn20 eutectic solder with a thickness of 12.7μm is preset on the surface to be bonded by the crimping method .

[0099] (3) Briquetting

[0100] The cover plate is an alumina...

Embodiment 2

[0107] See figure 1 with figure 2 :

[0108] (1) Forming the base

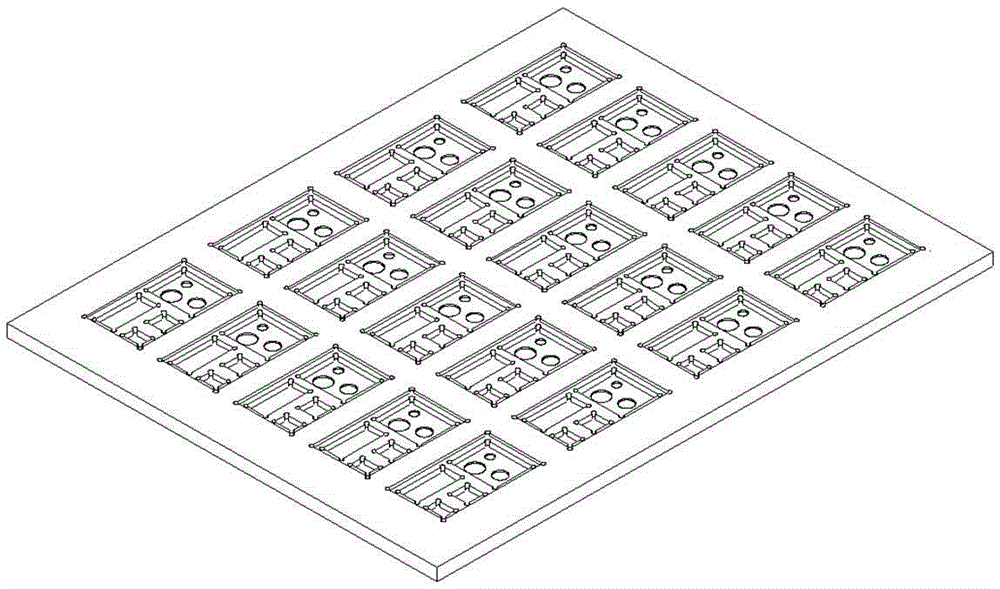

[0109] Using high-purity graphite precision processing, four-layer cavities are milled by CNC machine tools. Cavity I is opened according to the distribution position of the dielectric bridge on the surface of the chip. Cavity II is used for chip placement and positioning. The cavity size is consistent with the chip eutectic position. The cavity height and chip thickness are 30μm lower. The size of the surface cavity is the same as that of the substrate, and the height is slightly lower than the thickness of the substrate by 30μm. The specific structure is as follows image 3 Shown.

[0110] (2) Substrate pretreatment

[0111] The substrate is a high thermal conductivity W85Cu15 alloy sheet, which is machined into the required 10mm×6mm×2mm, and the surface is plated with Au / Ni plating. Pb37Sn63 eutectic solder with a thickness of 0.06mm is preset on the surface to be bonded by crimping.

[0112] (3) Briquetting

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com