High-reliability ultra-small metal ceramic surface-mounted device packaging process

A technology of metal ceramics and packaging technology, which is applied in the field of device packaging, can solve the problems of weak welding between chips and shells, not being widely used, and weak bonding of bonding wires, and achieves easy automation, easy integration, and low weight. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles of the present invention are further described and explained below so that those skilled in the art can better understand the present invention. To be limited, all improvements within the idea of the present invention should be within the protection scope of the present invention.

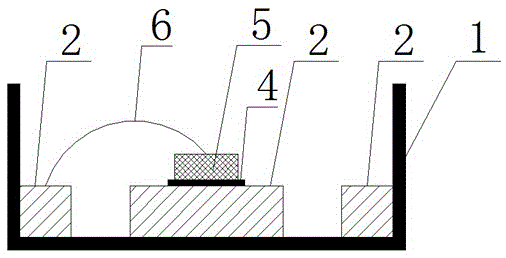

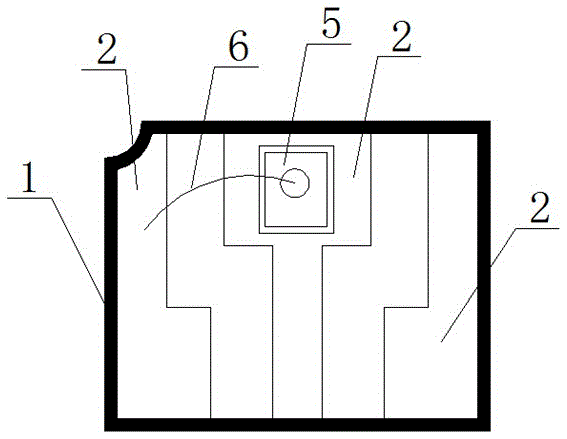

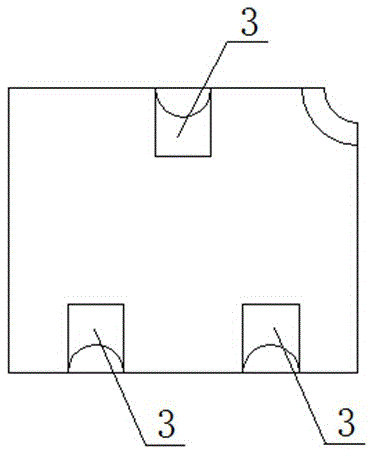

[0033] Such as Figure 1~3 As shown, it is a schematic diagram of a UB package device, Figure 4-6 Shown is a schematic diagram of a UA-type packaged device, the surface mount device includes a package 1, the tube core of the package 1 and two ends are provided with conductive areas 2, the chip 5 is welded on the conductive area 2 at the tube core, the chip 5 and The conductive area 2 at the end of the shell is electrically connected through the bonding wire 6 , and the back of the shell 1 is provided with a lead-out terminal 3 , which is electrically connected to the conductive area 2 . Compared with traditional devices, the highly reliable ultra-small cermet surface moun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com