Mode-locked fiber laser and pulse laser generation method

A technology of fiber lasers and mode-locked lasers, which is applied to lasers, laser components, phonon exciters, etc., can solve the problems of complex structure, maintenance-free and poor reliability, and achieve simple structure, reliability, maintenance-free, and easy engineering application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

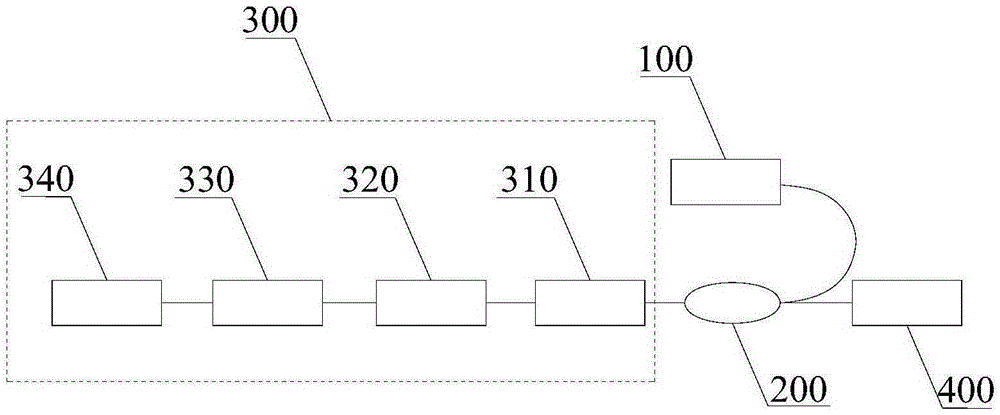

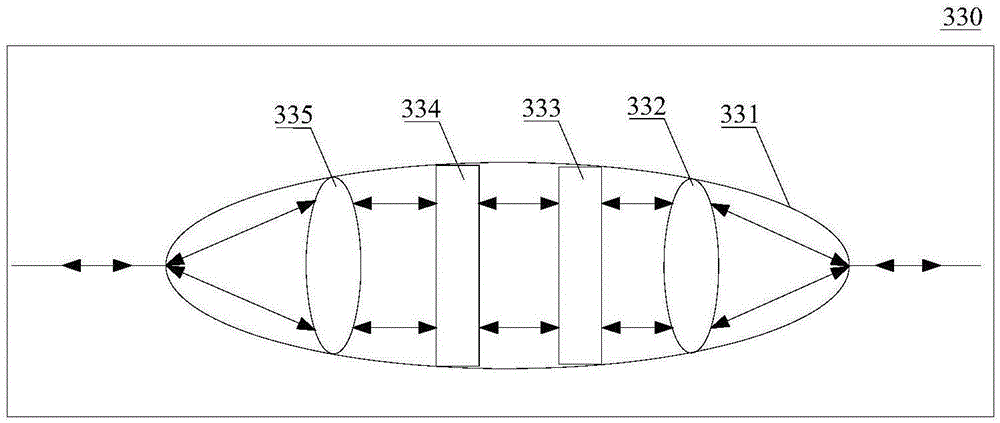

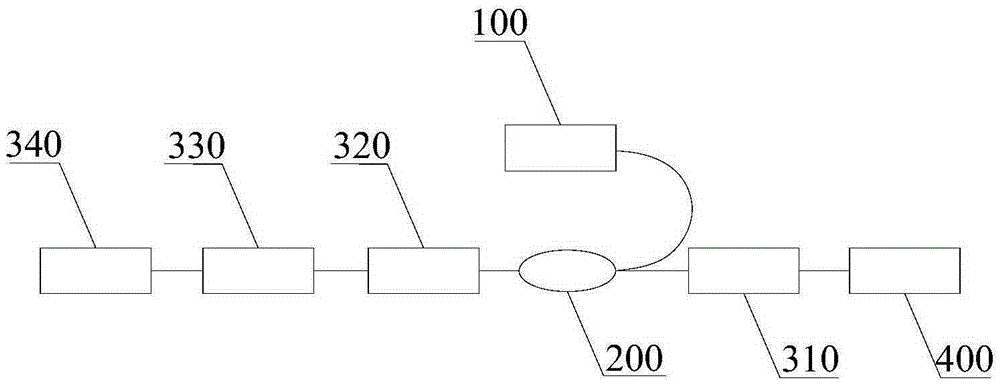

[0036] An embodiment of the present invention provides a mode-locked fiber laser for outputting pulsed laser light, including: a pump source 100 and a mode-locked laser resonator 300 . Such as figure 1 As shown, the mode-locked laser resonator 300 further includes a reflection component 310 , a gain fiber 320 , a polarization-maintaining filter 330 and a saturable absorber mirror 340 for mode-locking, which are sequentially coupled.

[0037]The reflective component 310 and the saturable absorbing mirror 340 are used to make the signal light generated by the gain fiber 320 oscillate multiple times in the mode-locked laser resonator 300 to output the mode-locked pulse laser. Wherein, the reflecting part 310 is mainly used for outputting the mode-locked pulsed laser, outputting a part of the mode-locked pulsed laser, and reflecting the other part back into the mode-locked laser resonator 300 to continue to oscillate. For example, a fiber grating or a laser output mirror can be us...

no. 2 example

[0050] Such as Figure 4 As shown, the embodiment of the present invention provides a pulsed laser generation method, which is applied to the mode-locked fiber laser provided in the first embodiment above, and the method includes:

[0051] Step S401: the gain fiber generates signal light according to the pump light emitted by the pump source, and outputs the signal light to the polarization maintaining filter;

[0052] Step S402: the polarization-maintaining filter processes the received signal light into signal light with a preset polarization direction and a preset wavelength range and outputs it to a saturable absorbing mirror;

[0053] Step S403: The saturable absorber performs mode-locking on the signal light in the preset polarization direction and preset wavelength range, and then transmits it to the polarization-maintaining filter;

[0054] Step S404: the gain fiber amplifies the signal light output by the polarization maintaining filter and transmits it to the reflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com