Magnetic cam driving unit, vibration table device and linear driving device

A driving unit and cam technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of poor control accuracy, low energy utilization rate, complex structure, etc., and achieve large driving torque, high energy utilization rate and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

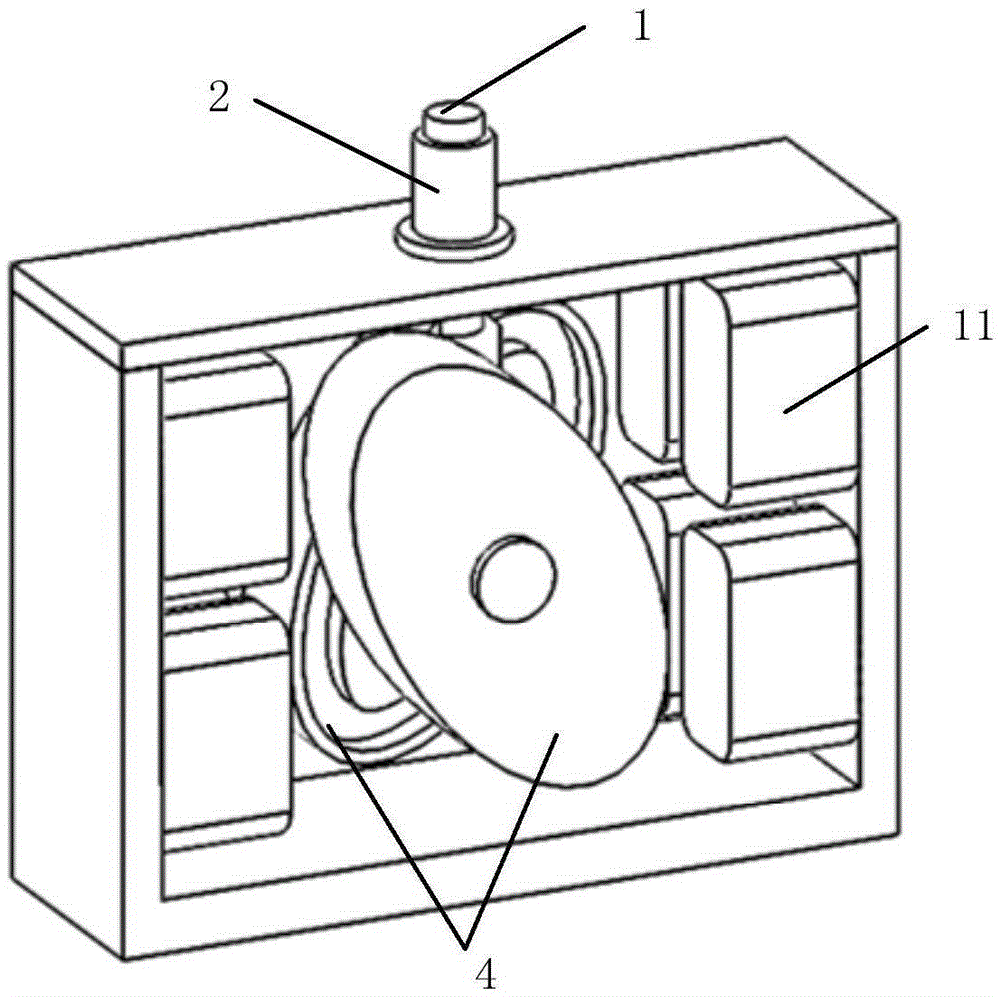

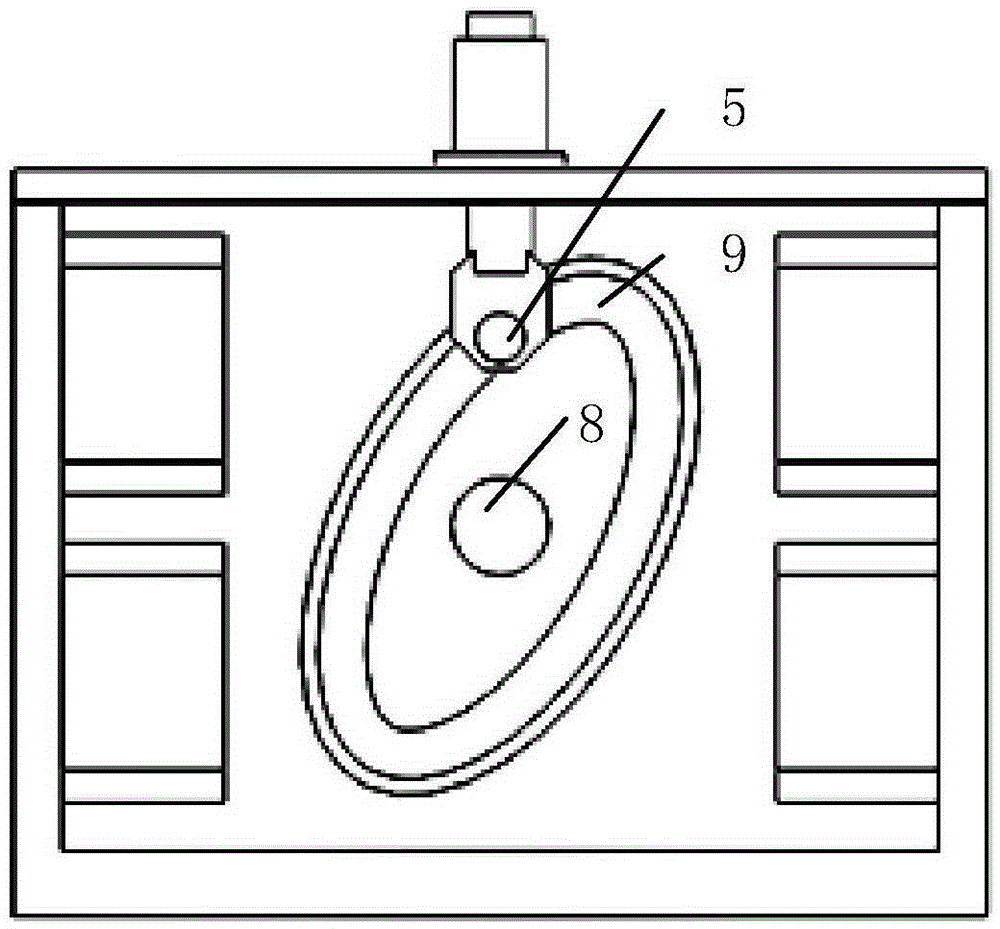

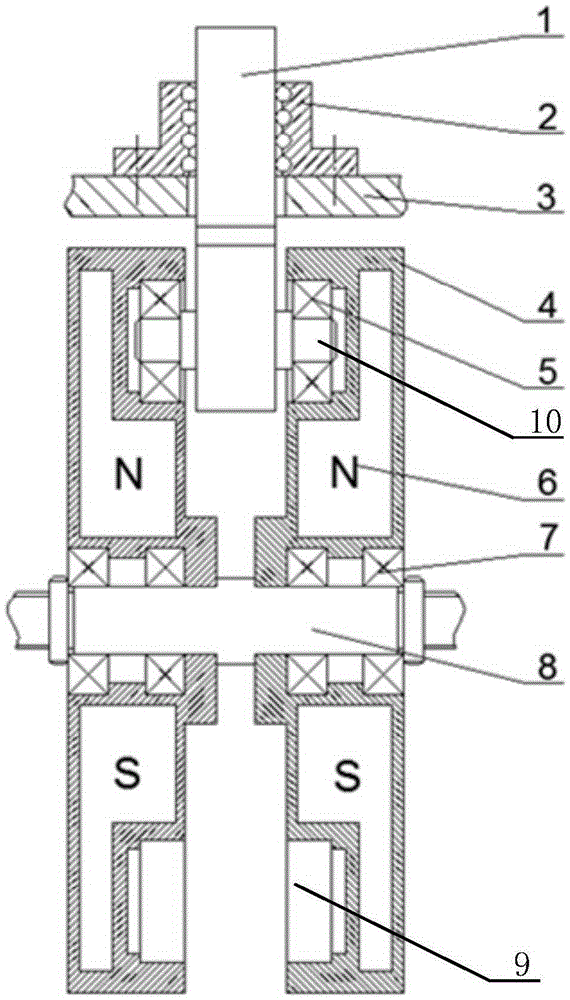

[0076] The first embodiment of the present invention is a preferred example of the basic embodiment. like Figure 1 to Figure 6 As shown, in this embodiment, the cam adopts a pair of conjugated cams; the pair of conjugated cams rotates around the cam support shaft, and are respectively equipped with first magnets (permanent magnets); the pair of conjugated cams The opposite surfaces are respectively provided with annular grooves with consistent contours; one end of the push rod is provided with a push rod support shaft, and two groove bearings are respectively installed on both ends of the push rod support shaft, and the two groove bearings are respectively arranged In the respective annular grooves of the pair of conjugated cams; the grooved bearings can only move along the annular grooves; the push rod is guided by the linear bearings fastened on the support plate; in the pair of conjugated cams Under the magnetic force exerted by the second magnet, the two conjugate cams c...

no. 2 example

[0082] The second embodiment of the present invention is a preferred example of the basic embodiment. like Figure 9 , Figure 10 As shown, in this embodiment, one end of the push rod is connected to the roller, and the curved surface profile of the cam drives the push rod through the roller; the first magnet includes one or more permanent magnets; the second magnet includes a plurality of electromagnets, wherein, more Each electromagnet has an independent power supply circuit, that is, multiple electromagnets can apply magnetic force to the first magnet alone; the permanent magnet is flat, and multiple electromagnets are arranged on one side or both sides of the permanent magnet; the first magnet, the second The two magnets interact to form a magnetic circuit structure. Under the overall excitation of the plurality of electromagnets, the first magnet rotates from an angle corresponding to a smaller magnetic flux in the magnetic circuit structure to an angle corresponding to ...

no. 3 example

[0087] The third embodiment of the present invention is a preferred example of the basic embodiment, and also a modification example of the second embodiment. In this embodiment, the number of first magnets and second magnets is one or more groups; in each group of first magnets and second magnets, the number of electromagnets located on either side of the first magnet is equal to the number of permanent magnets. quantity. A plurality of permanent magnets are evenly distributed in the circumferential direction; a plurality of electromagnets are evenly distributed in the circumferential direction.

[0088] Specifically, the first magnet and the second magnet can adopt various methods. like Figure 15 , Figure 16 , Figure 17 Shown is the arrangement of multiple permanent magnets in a single plane. This arrangement allows multiple permanent magnets to be simultaneously stressed in different orders during the rotation of the cam, making the rotation of the cam more stable an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com